Bamboo straw manufacturing equipment for beverage shop

A technology for manufacturing equipment and beverage stores, applied in the direction of mechanical equipment, manufacturing tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

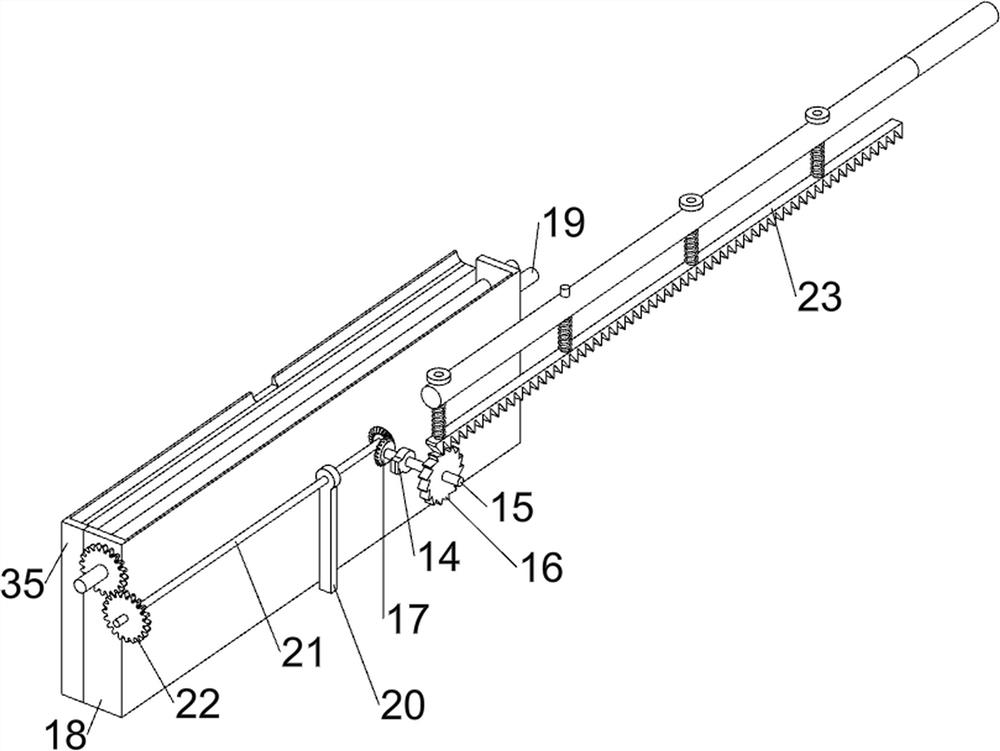

[0025] A kind of bamboo straw manufacturing equipment for beverage shops, such as figure 1 As shown, it includes a base 1, a cylinder 2, a drilling mechanism 3 and a propulsion mechanism 4. A cylinder 2 is provided on the right rear side of the upper part of the base 1, a drilling mechanism 3 is provided on the right side of the upper part of the base 1, and a drilling mechanism 3 is provided on the upper left side of the base 1. Propulsion mechanism4.

[0026] When you need to make wooden straws, you can use this equipment. First, place the bamboo strips for making straws in the propulsion mechanism 4, then open the cylinder 2, move forward through the cylinder 2, and drive the propulsion mechanism 4 to push a bamboo strip Push it into the drilling mechanism 3, and then drive the drilling mechanism 3 to drill the bamboo strips through the cylinder 2. After the drilling is completed, close the cylinder 2.

Embodiment 2

[0028] On the basis of Example 1, as Figure 2-6 As shown, the drilling mechanism 3 includes a presser 30, a drill bit 31, a first slide rail 32, a special-shaped block 33, a first spring 34, a clamping groove 35 and an elastic hard sheet 36, and the front side of the cylinder 2 is provided with a drill bit 31. , the drill bit 31 is provided with a presser 30, the base 1 top right front side is provided with a first slide rail 32, the first slide rail 32 is provided with a special-shaped block 33 slidingly, and the special-shaped block 33 is connected with the first slide rail 32 There is a first spring 34, and a clamping groove 35 is provided on the right front side of the upper part of the base 1, and two elastic hard plates 36 are provided in a rotating manner on the right side of the clamping groove 35.

[0029] When the bamboo strip is located in the clamping groove 35, the elastic hard sheets 36 on both sides can withstand the right side of the bamboo strip to prevent th...

Embodiment 3

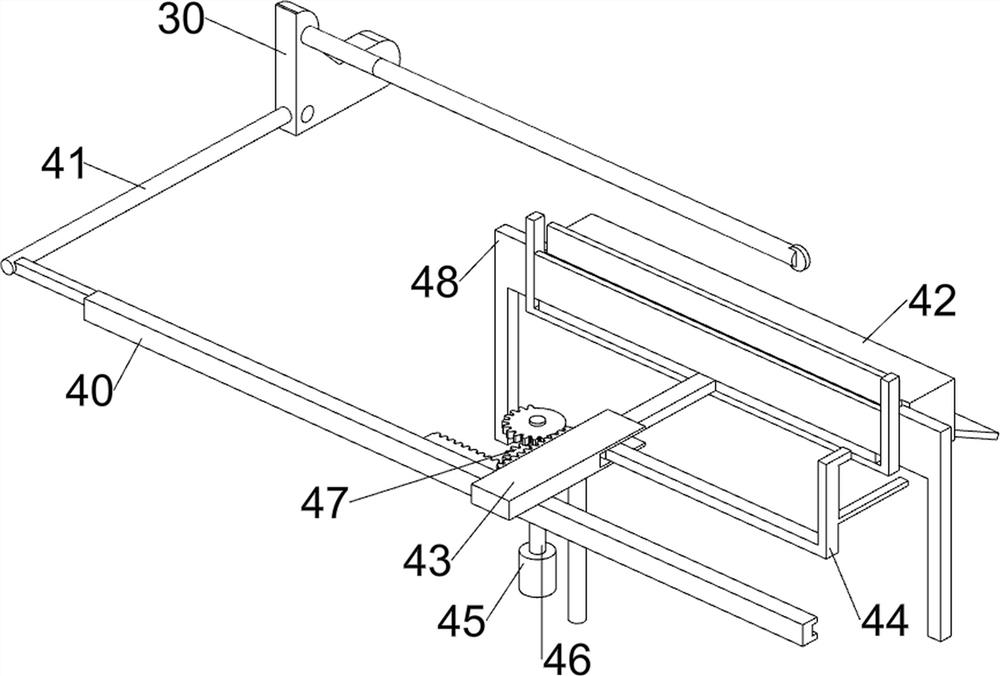

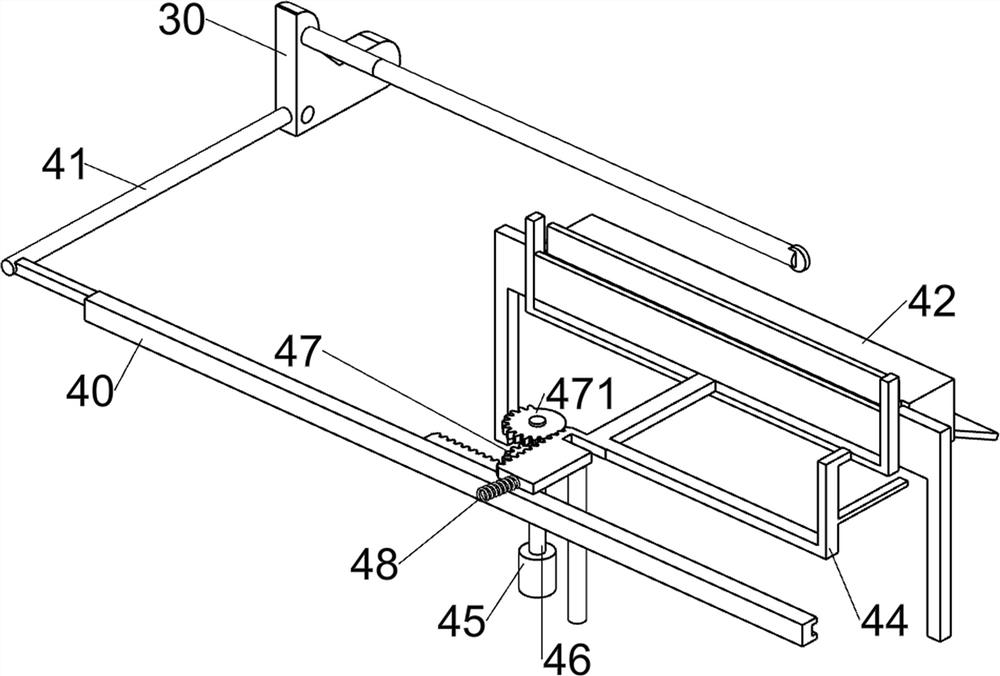

[0033] On the basis of Example 2, such as figure 1 and Figure 7-9 As shown, it also includes a first material box 5, a second rotating shaft 6, a feeding tooth 7, a first ratchet bar 8 and a second ratchet tooth 9, and the front side of the upper part of the base 1 is provided with the first material box 5, the first material Inside the case 5, a second rotating shaft 6 is provided in a rotating manner, and a feeding tooth 7 is arranged symmetrically front and back on the second rotating shaft 6. The front side of the second rotating shaft 6 is provided with a second ratchet 9, and the front side of the second rack 44 is connected with The first ratchet strip 8 cooperates with the second ratchet tooth 9 .

[0034] The user can place the bamboo strips in the first material box 5, and the second rack 44 moves to the left to drive the first ratchet bar 8 to move to the left, thereby driving the second ratchet 9, the second rotating shaft 6 and the two upper ratchets. The feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com