Grinding device capable of following steel nails in self-adaptive mode

A self-adaptive, steel nail technology, which is applied in the direction of grinding drive devices, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problem that the steel nail grinding device cannot self-adaptively follow the size and changes of steel nails, and achieve installation And easy disassembly, strong practicability, and the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

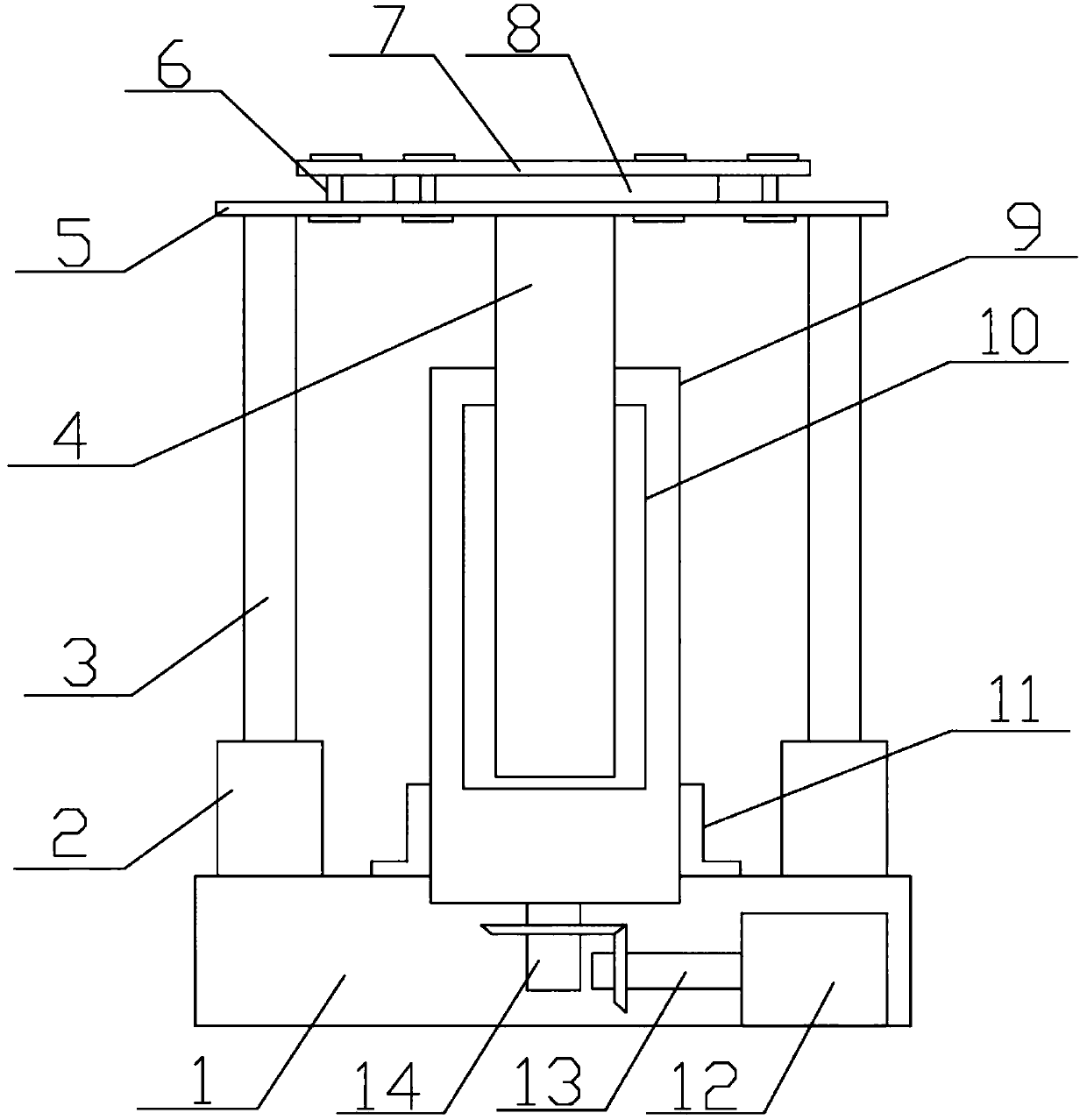

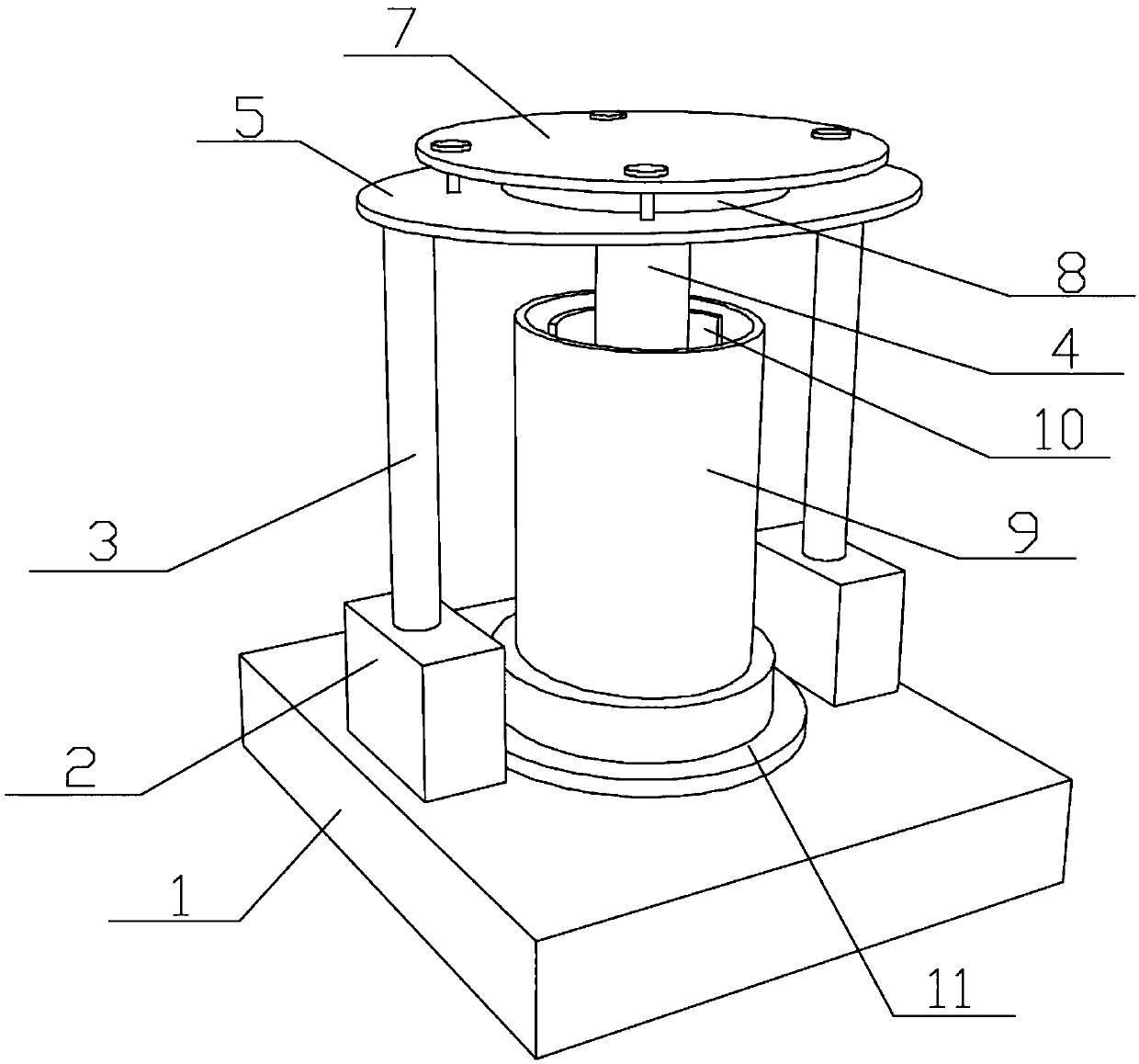

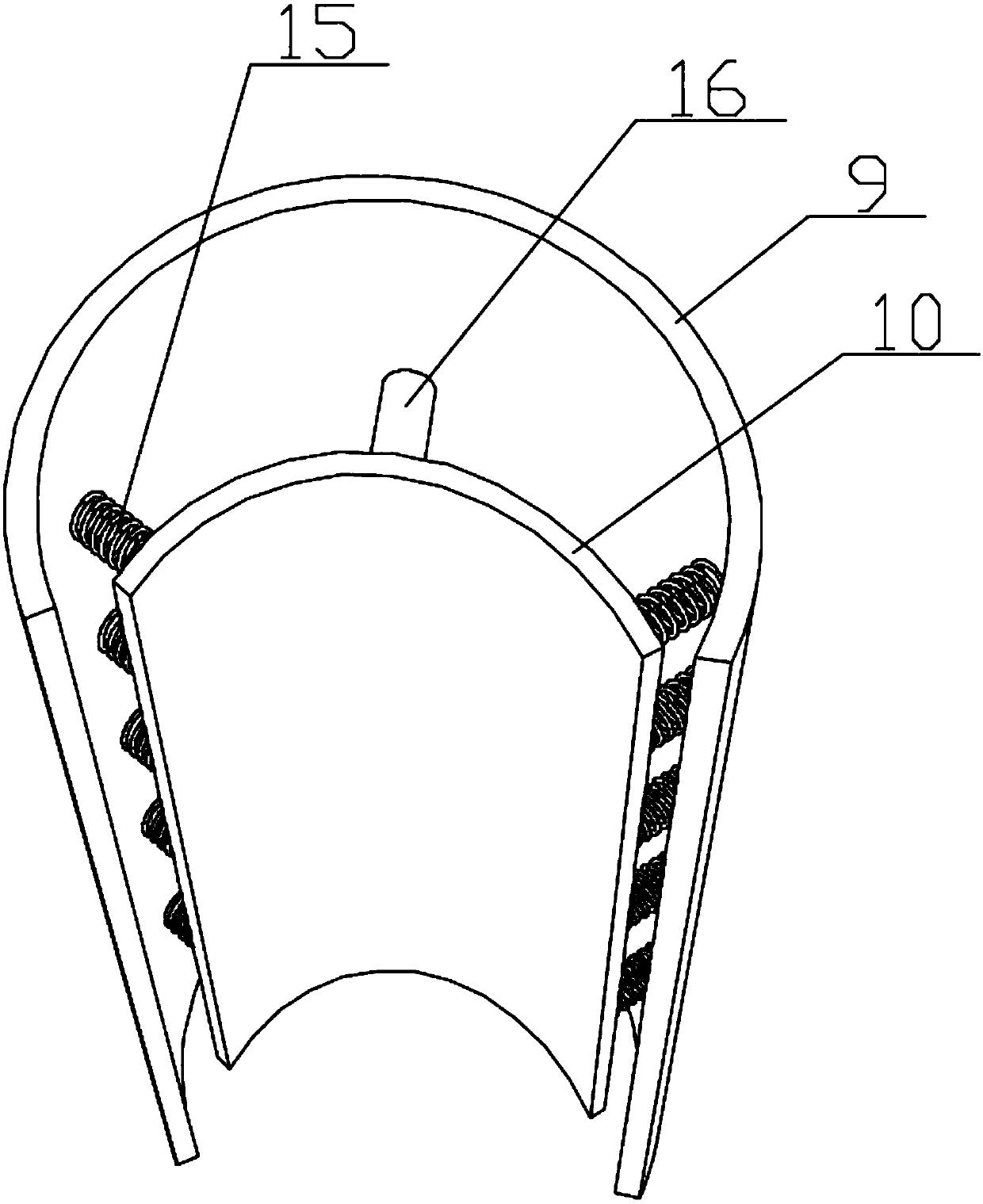

[0026] A grinding device capable of self-adaptively following steel nails, comprising a steel nail fixing device, a base 1 is provided below the steel nail fixing device, and a rotatable grinding cylinder 9 with a top opening is fixed on the base 1, and the grinding cylinder 9 An arc-shaped piece 10 made of elastic material is arranged inside, the outer side of the arc-shaped piece 10 is fixed to the inner wall of the grinding cylinder 9 by a fixed rod 16, and the outer side of the arc-shaped piece 10 near the side is connected to the inner wall of the grinding cylinder 9 by a spring 15, The inner side of the arc part 10 is provided with steel wire bristles for grinding the nail body 4 .

[0027] When the present invention is in use, after the steel nail is fixed by the steel nail fixing device, the nail body 4 of the steel nail extends into the grinding cylinder 9, and the steel wire bristles on the inner side of the arc-shaped part 10 are kept under the action of the fixing r...

Embodiment 2

[0029] Based on Embodiment 1, a bearing seat 11 is fixed on the base 1, and a bearing is installed in the bearing seat 11, and the lower end of the grinding cylinder 9 is connected to the bearing; the bottom of the grinding cylinder 9 extends into the base 1 and is connected to a rotating shaft 14. The base 1 is provided with a motor 12 for driving the rotating shaft 14 to rotate. The bearing can play the role of supporting the grinding cylinder 9 on the one hand, and on the other hand, can also ensure that the grinding cylinder 9 rotates. The present invention drives the rotating shaft 14 to rotate through the motor 12, thereby driving the grinding cylinder 9 to rotate.

Embodiment 3

[0031] Based on the second embodiment, the rotating shaft 14 and the output shaft 13 of the motor 12 are transmitted through gears. Gear transmission has the characteristics of high efficiency, compact structure, reliable operation and long life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com