Patents

Literature

36results about How to "Improve the degree of adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

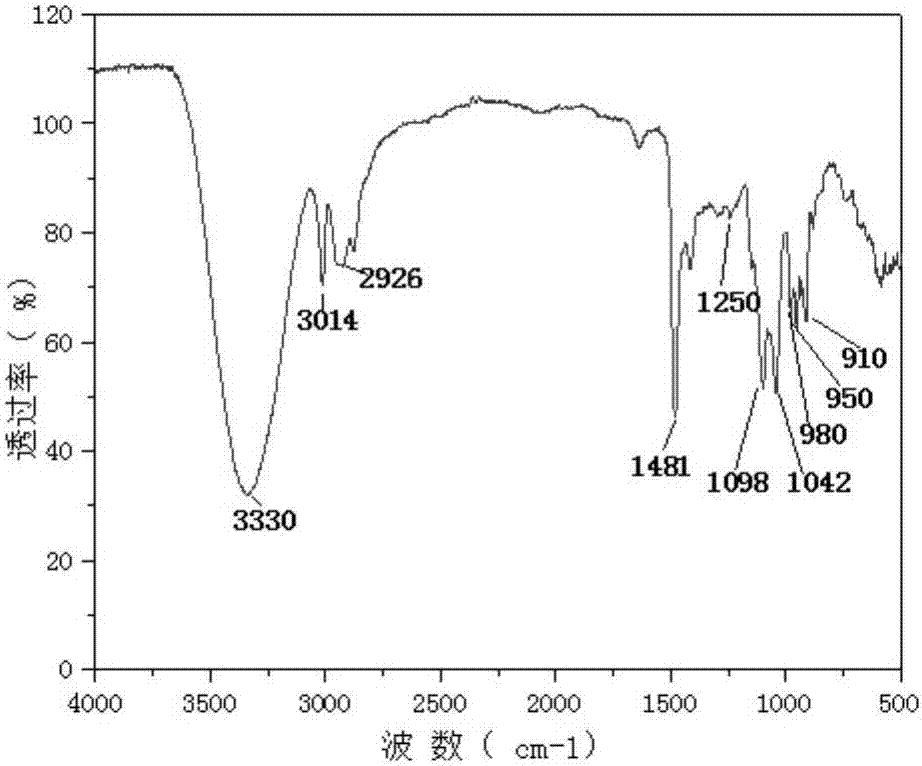

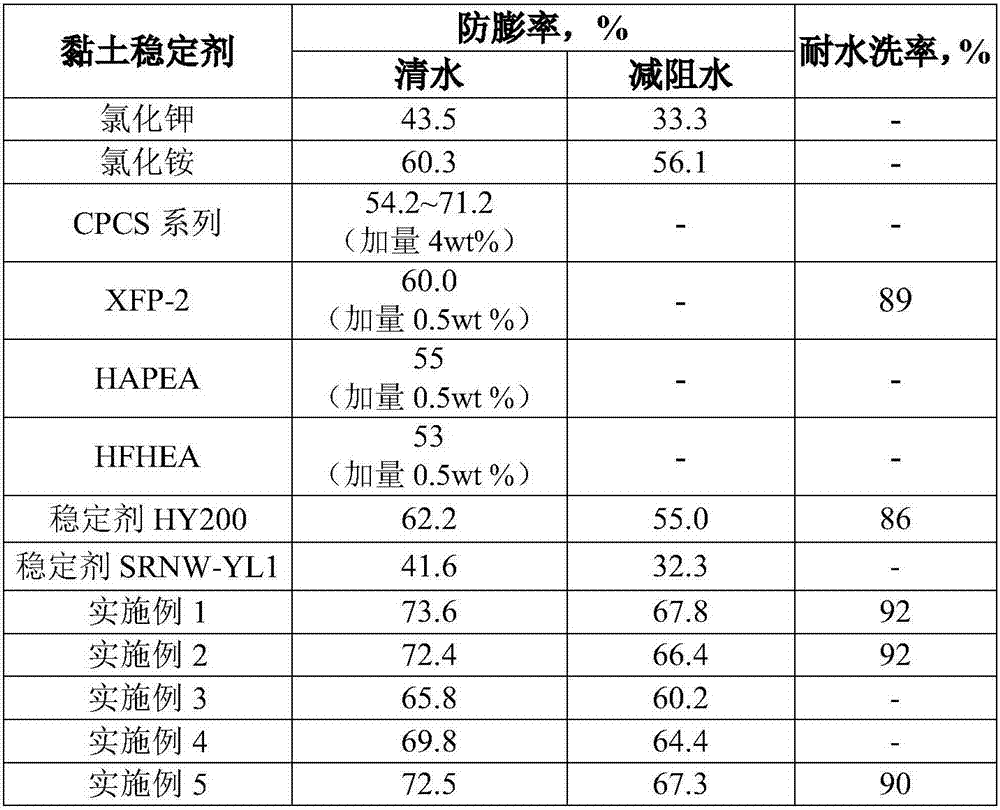

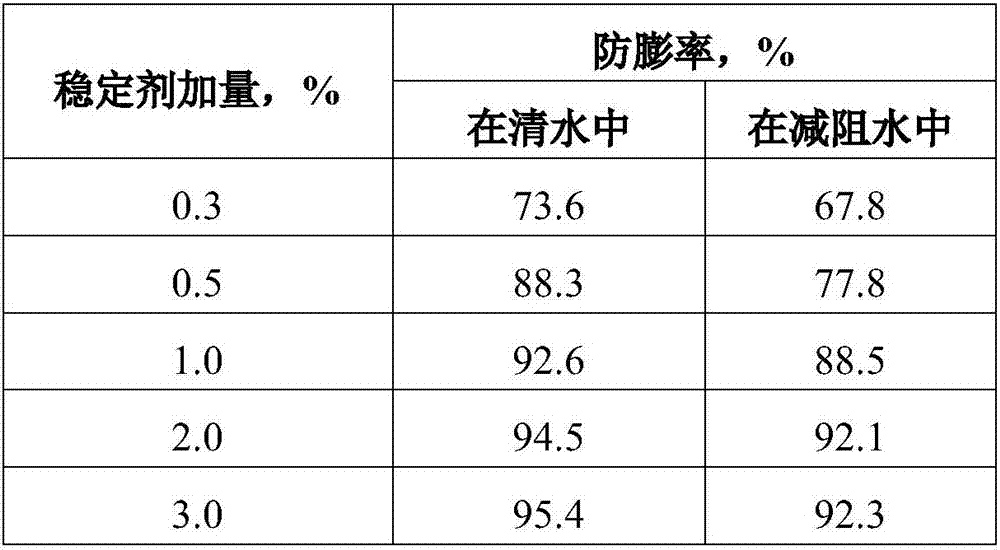

Clay stabilizer and applications thereof

ActiveCN107312507AImprove the degree of adsorptionImprove the degree of reaction conversionDrilling compositionEpichlorohydrinAqueous solution

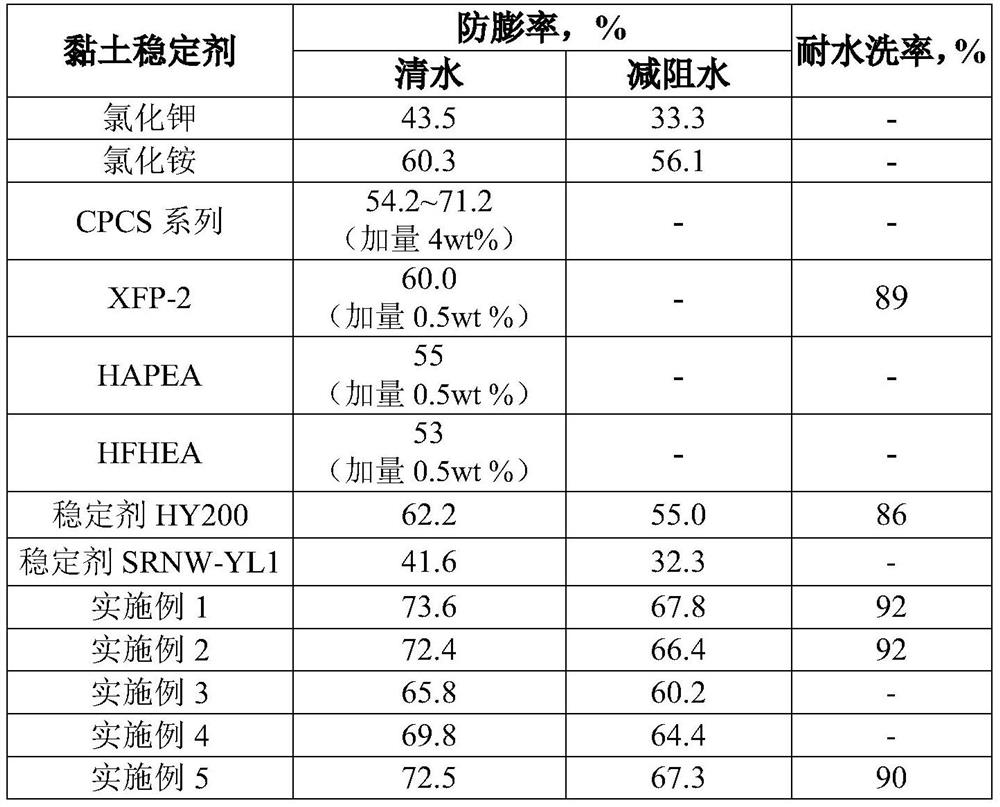

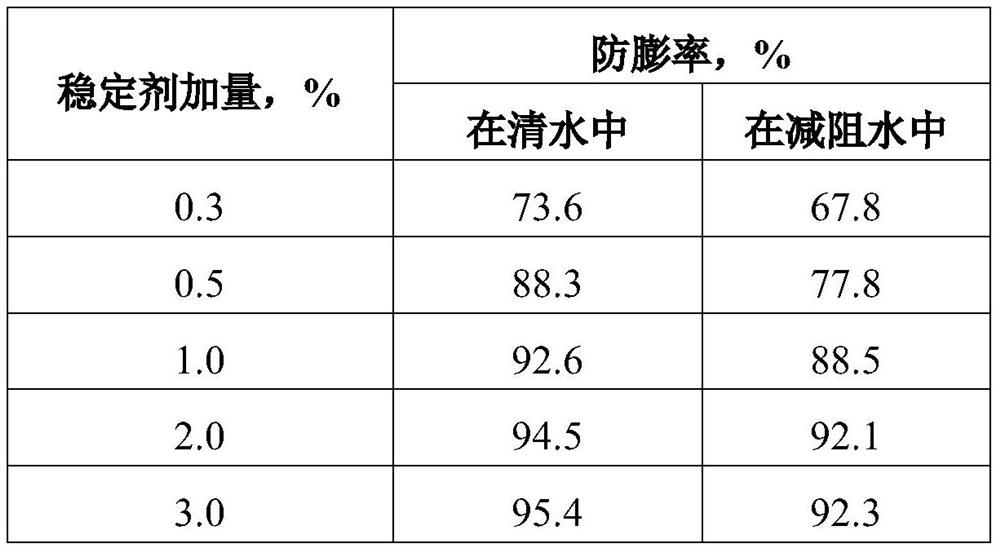

The present invention relates to a preparation method of a clay stabilizer for low permeability stratum. The preparation method sequentially comprises: adding epichlorohydrin to the aqueous solution of a monoaliphatic amine, carrying out a reaction for a certain time, adding epichlorohydrin, heating, carrying out a reaction, adding polyamine, adding epichlorohydrin, carrying out a reaction, and drying to obtain the clay stabilizer.

Owner:CHINA PETROLEUM & CHEM CORP +1

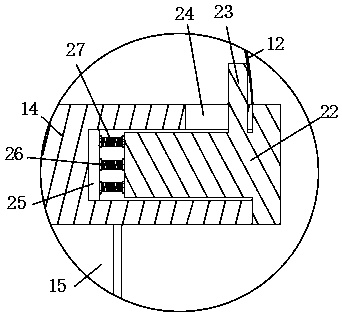

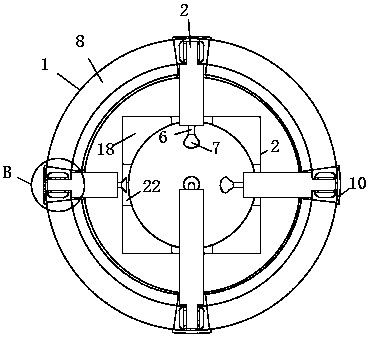

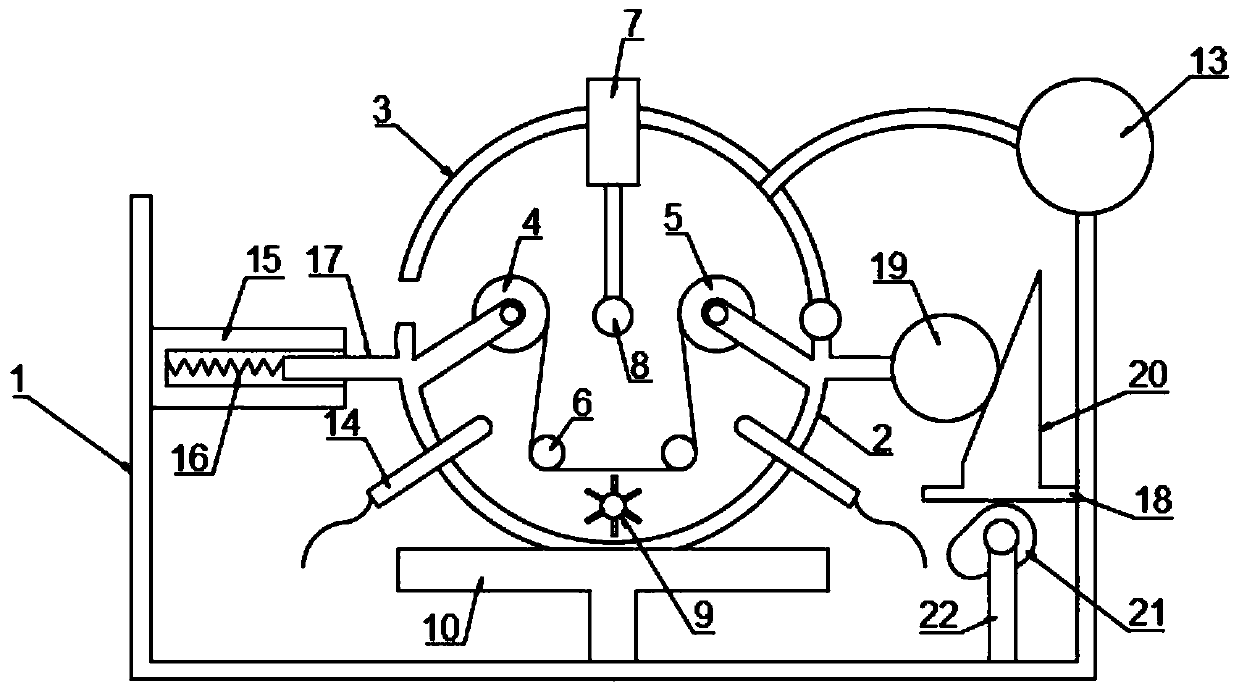

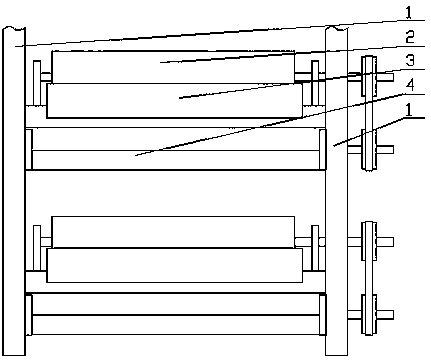

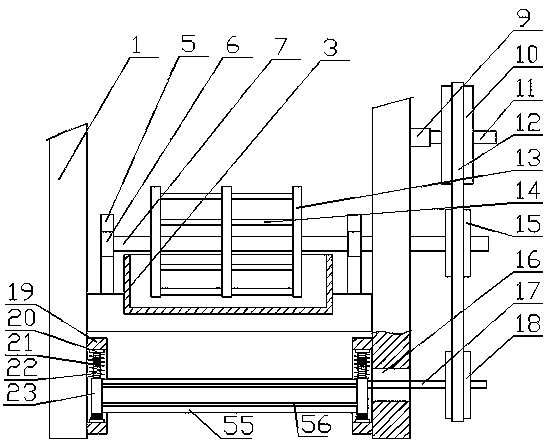

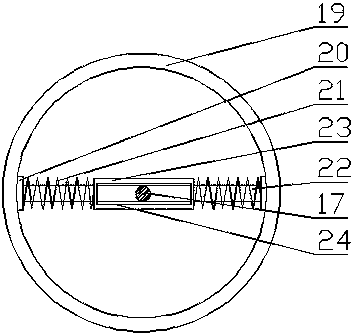

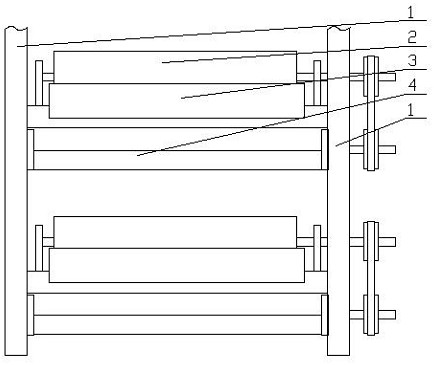

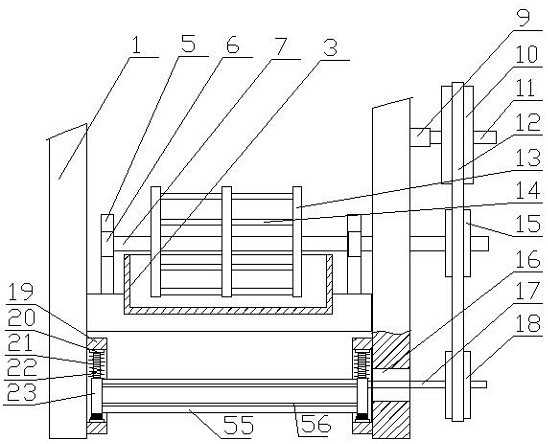

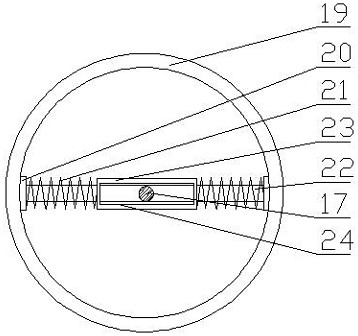

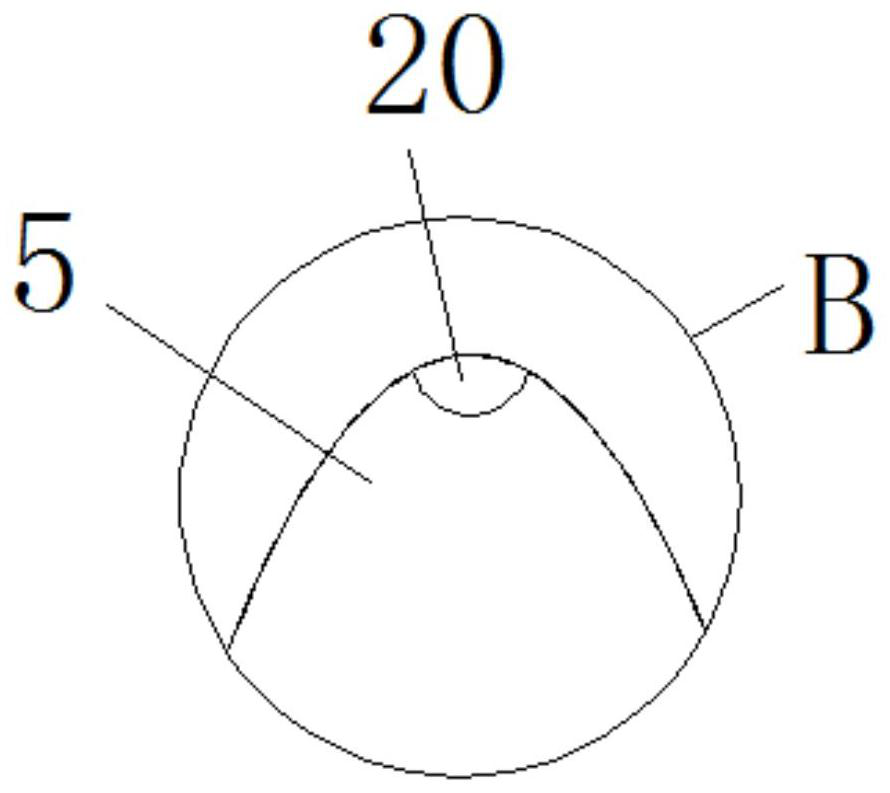

Anti-slippage composite base material boiler body outer surface polishing and grinding machine

PendingCN108544360AImprove the degree of adsorptionImprove stabilityGrinding carriagesPolishing machinesPulp and paper industryBolt connection

The invention provides an anti-slippage composite base material boiler body outer surface polishing and grinding machine. The anti-slippage composite base material boiler body outer surface polishingand grinding machine comprises a polishing mechanism and a clamping mechanism. Supporting columns are arranged on the outer side of the polishing mechanism. Polishing rack fixing bases are arranged atthe upper ends of the supporting columns an integral forming manner. The polishing rack fixing bases are in bolt connection to the tail ends of polishing racks through fastening bolts. Polishing wheel shafts are fixedly connected to the front ends of the polishing racks. The front ends of the polishing wheel shafts are fixedly connected with polishing wheels. Stable plates are arranged at the lower ends of the supporting columns and internally fixedly connected with sliding wheels. The sliding wheels are in sliding connection into sliding grooves, and the sliding grooves are in a circular ring shape and are fixedly formed outside the clamping mechanism. A containing plate is arranged at the upper end of the clamping mechanism, each of the four side edges of the containing plate is fixedlyconnected with a spring buckle, and a vacuum suction pipe is arranged in the middle of the containing plate. According to the anti-slippage composite base material boiler body outer surface polishingand grinding machine, the angle of the polishing racks can be adjusted, the polishing wheels can face the surfaces of boiler bodies different in height for grinding along the surfaces of the boiler bodies, polishing is more comprehensive and more thorough, the anti-slippage composite base material boiler body outer surface polishing and grinding machine can adapt to polishing of the boiler bodiesdifferent in height, and usage is more convenient.

Owner:PINGDINGSHAN MEIYI METAL PROD

Preparation method of high-strength waterproof plate

InactiveCN109233194ALarge specific surface areaImprove mechanical propertiesMaleic anhydrideCorn starch

Owner:佛山齐安建筑科技有限公司

Preparation method of hydrotalcite-like compound with uniform particle size and high stability

PendingCN110395753AAvoid uneven particle size distributionImprove structural strengthNanotechnologyHydrotalciteFiberCellulose

The invention discloses a preparation method of a hydrotalcite-like compound with a uniform particle size and high stability, and belongs to the technical field of metal oxide preparation. According to the method provided by the invention, bean dregs and starch are mixed, proteins and plant fibers in the bean dregs are hydrolyzed to produce amino acid, cellulose and the like respectively through ahigh-temperature high-pressure reaction, hydroxyl groups in the cellulose and the plant fibers are oxidized to form carboxyl groups by using sulfuric acid and potassium permanganate, the carboxyl groups and ethylene glycol are subjected to an esterification reaction, so that a part of ester compounds are coagulated at the surfaces of the fibers, the plant fibers are used to bind components of thehydrotalcite-like compound to avoid non-uniform distribution of particle sizes of the hydrotalcite-like compound product, and the compatibility of the hydrotalcite-like compound with other materialsis improved; and organic components such as the cellulose and saccharide compounds are extracted from the bean dregs and the starch, the organic matter and other components in the hydrotalcite-like compound form a binder adsorption effect, mixing and crystallizing nucleation are performed at a high temperature, so that the structural strength of the hydrotalcite-like compound is improved, and thedurability and stability of the hydrotalcite-like compound are enhanced.

Owner:王志胜

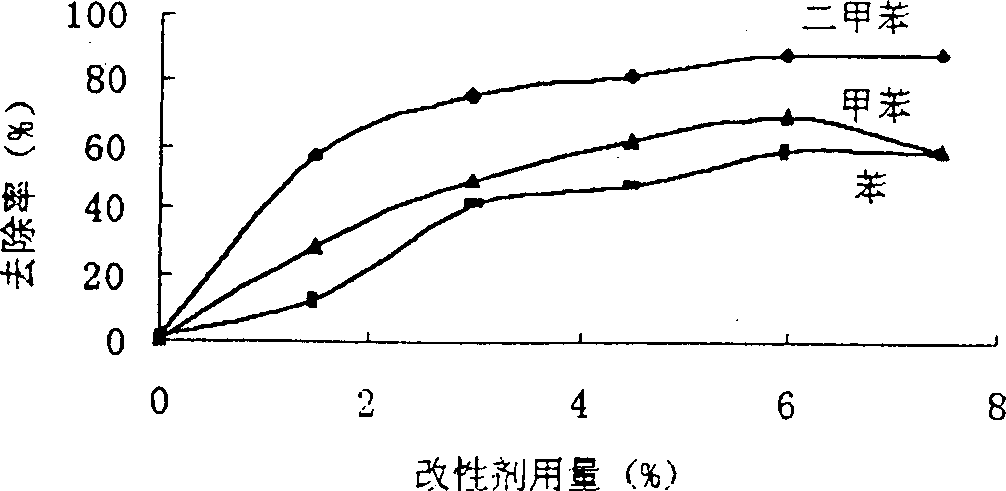

Acrylic factory waste gas treatment process

InactiveCN107899401AReduce the temperatureReduce pollutionDispersed particle separationIncinerator apparatusFiberActivated carbon

Owner:MACHENG ZHONGYOUSHUN BUILDING MATERIAL TECH CO LTD

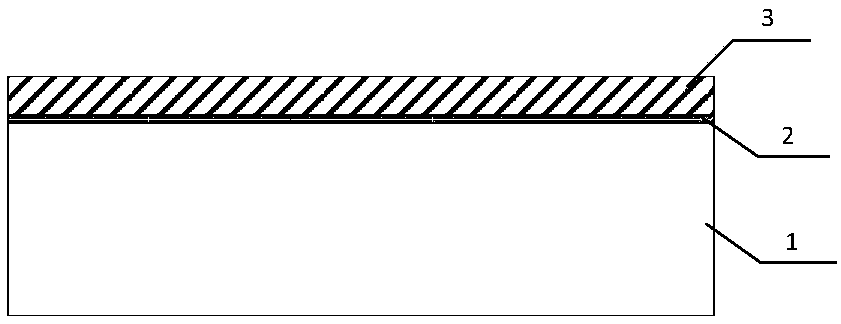

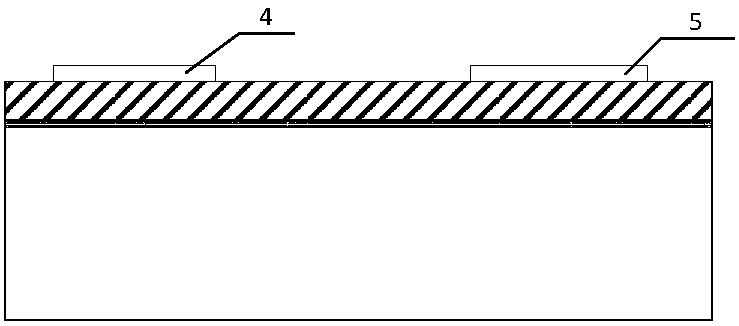

MEMS (Micro-Electro-Mechanical Systems) gas sensor and preparation method thereof

InactiveCN108152340AImprove the degree of adsorptionPromote absorptionMaterial capacitancePhysical chemistryBlack phosphorus

The invention belongs to the technical field of gas sensors, and relates to an MEMS (Micro-Electro-Mechanical Systems) gas sensor and a preparation method thereof. The MEMS gas sensor disclosed by theinvention sequentially consists of a substrate, a micro-beam structure, and a gas-sensitive layer, and the gas-sensitive layer is prepared from a Li atom-doped few-layer black phosphorus material. The gas sensor disclosed by the invention can be used for detecting CO gas, and has higher stability and sensitivity.

Owner:台州市吉吉知识产权运营有限公司

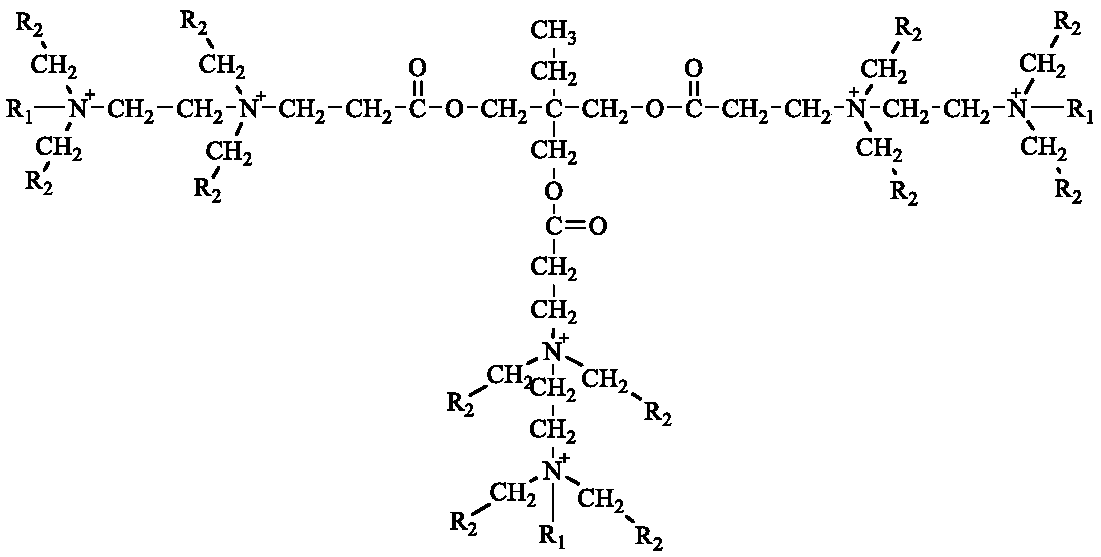

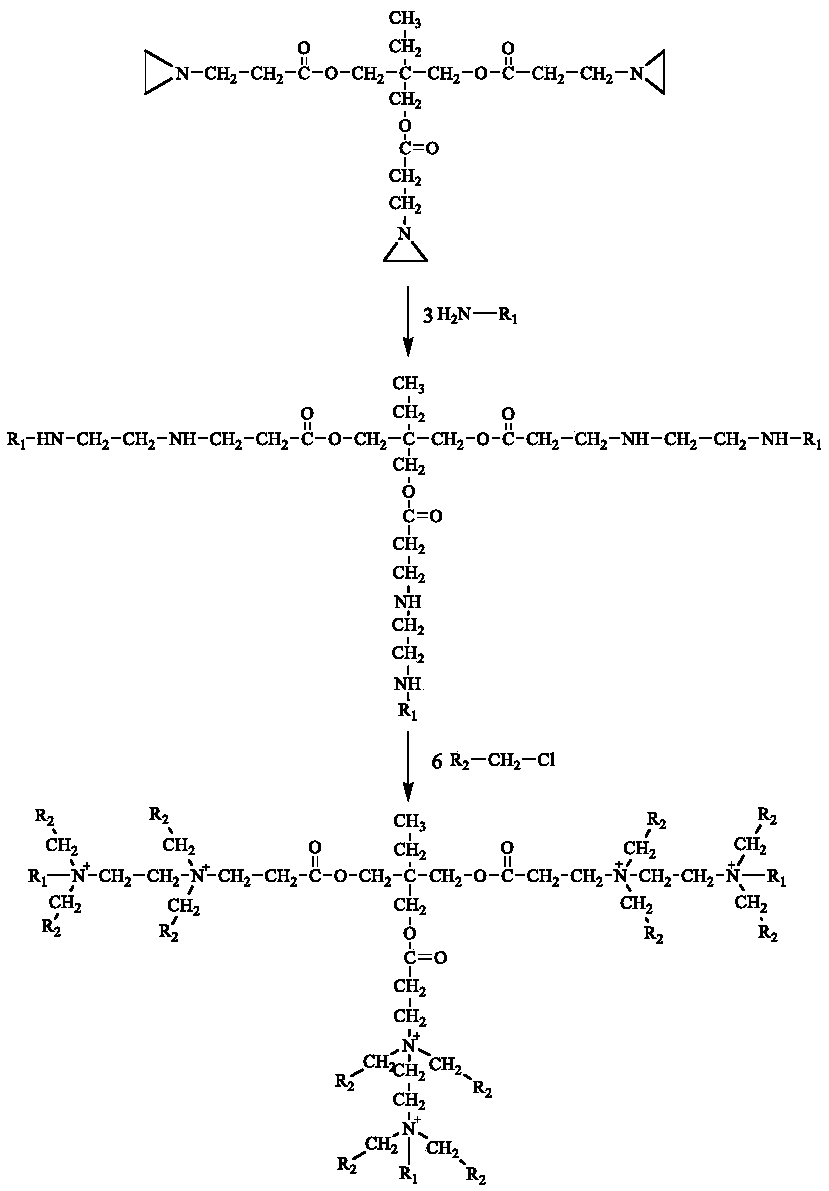

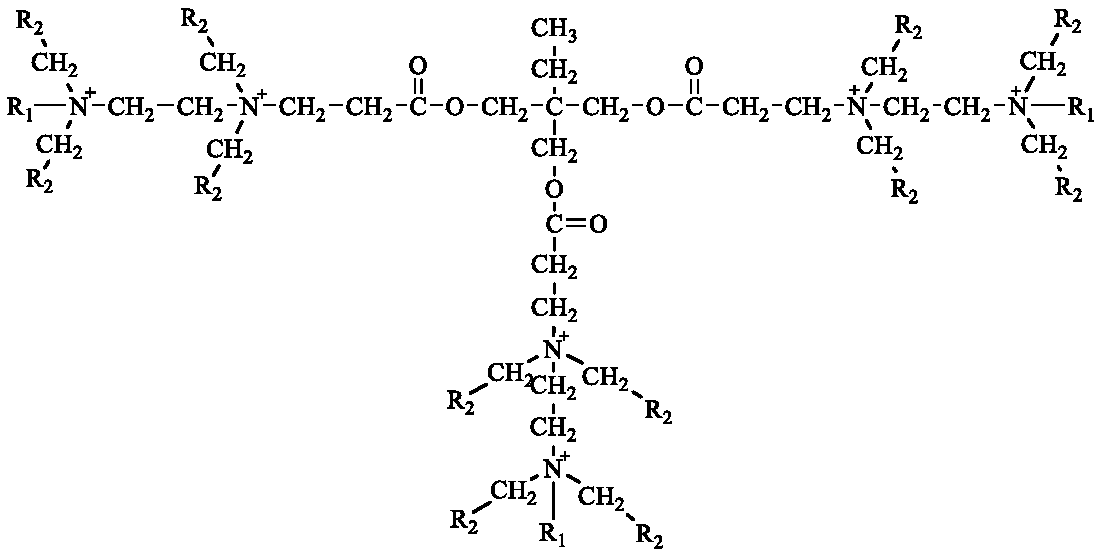

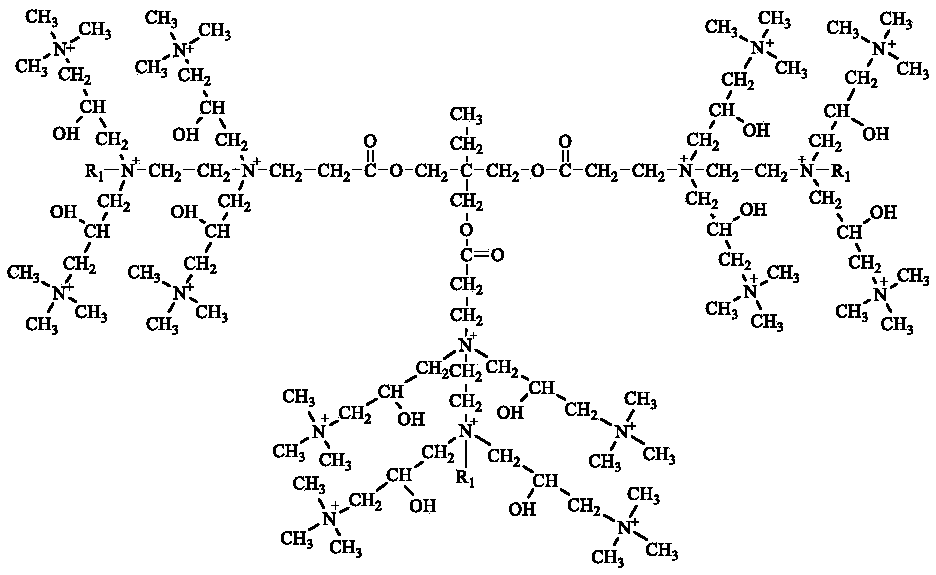

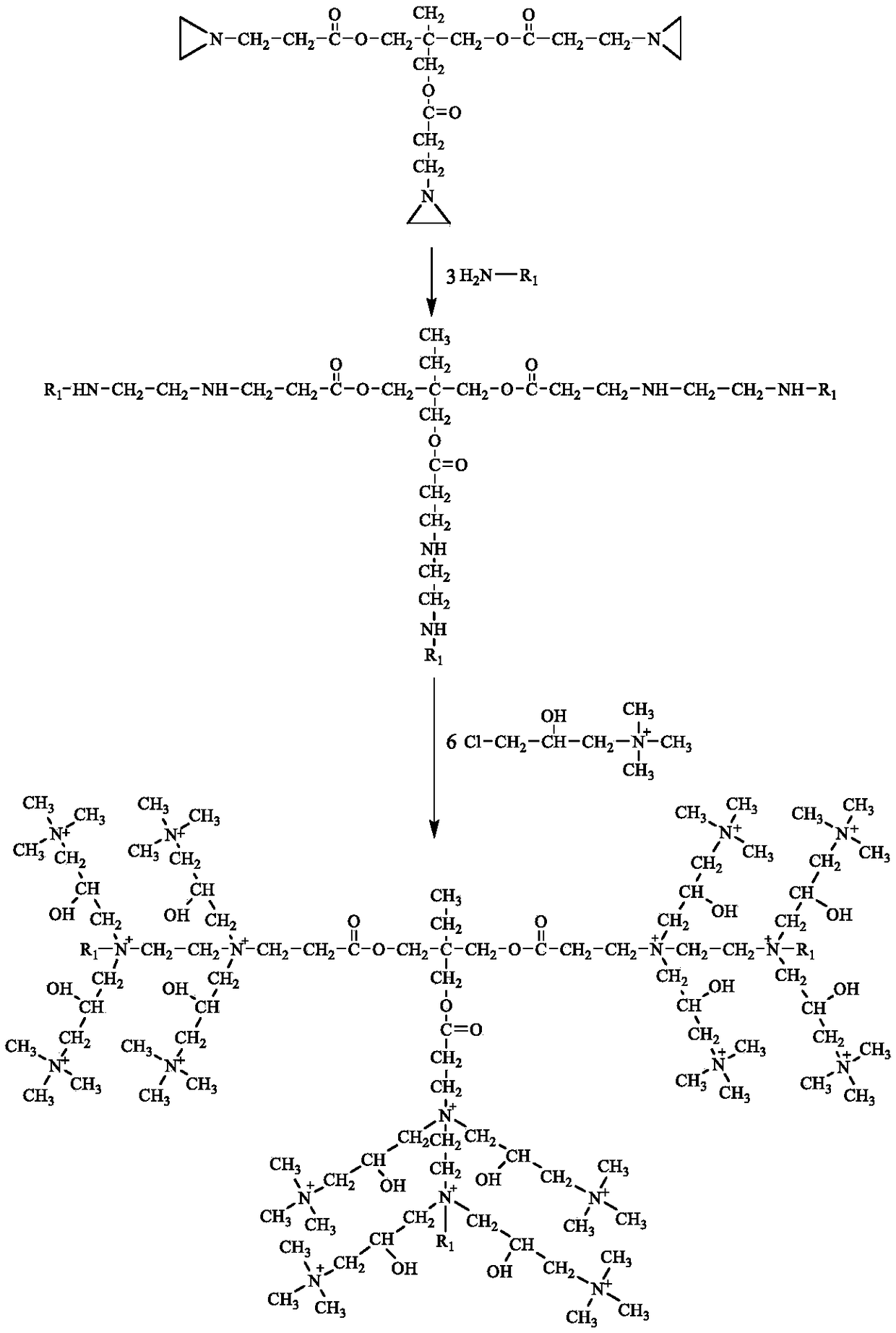

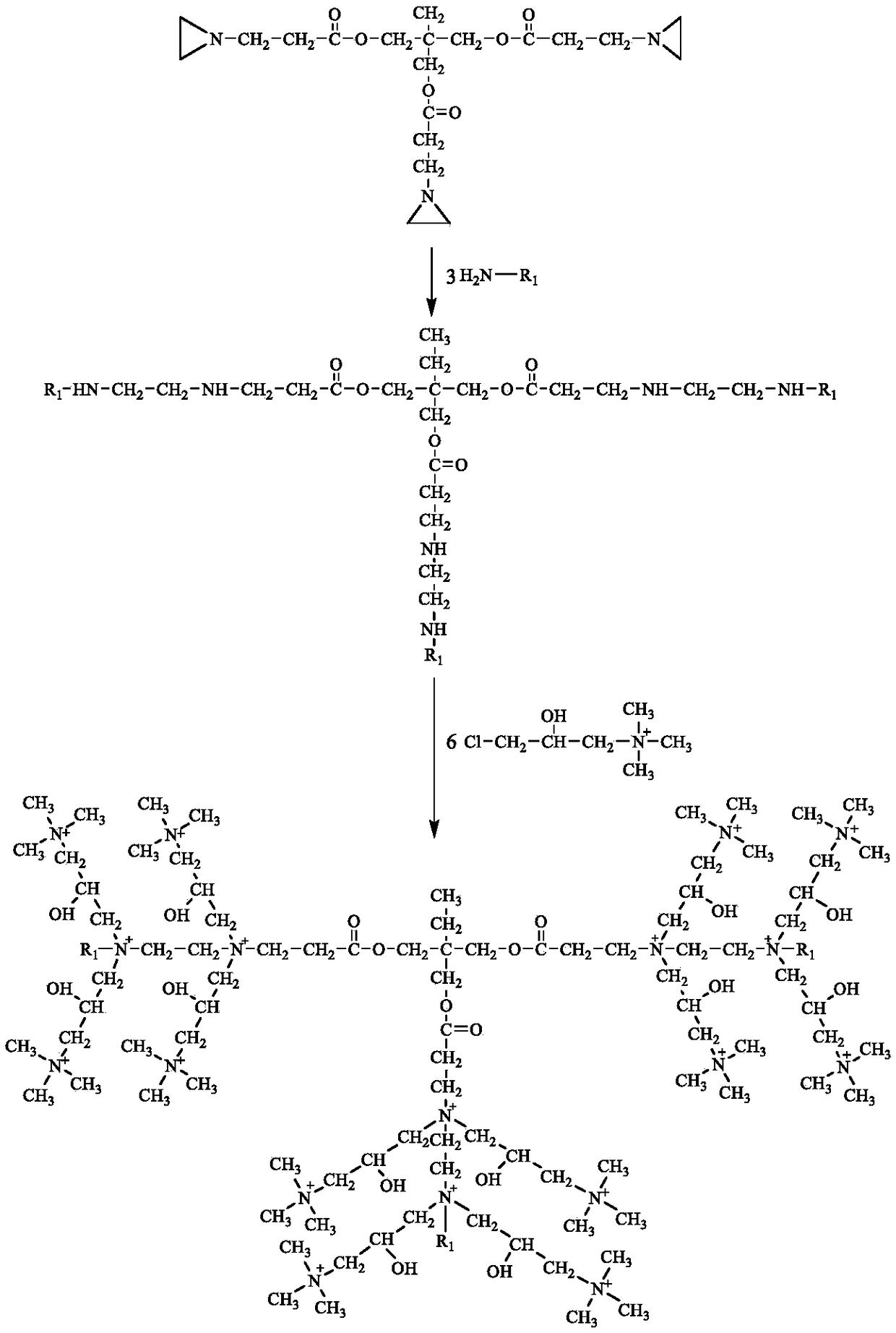

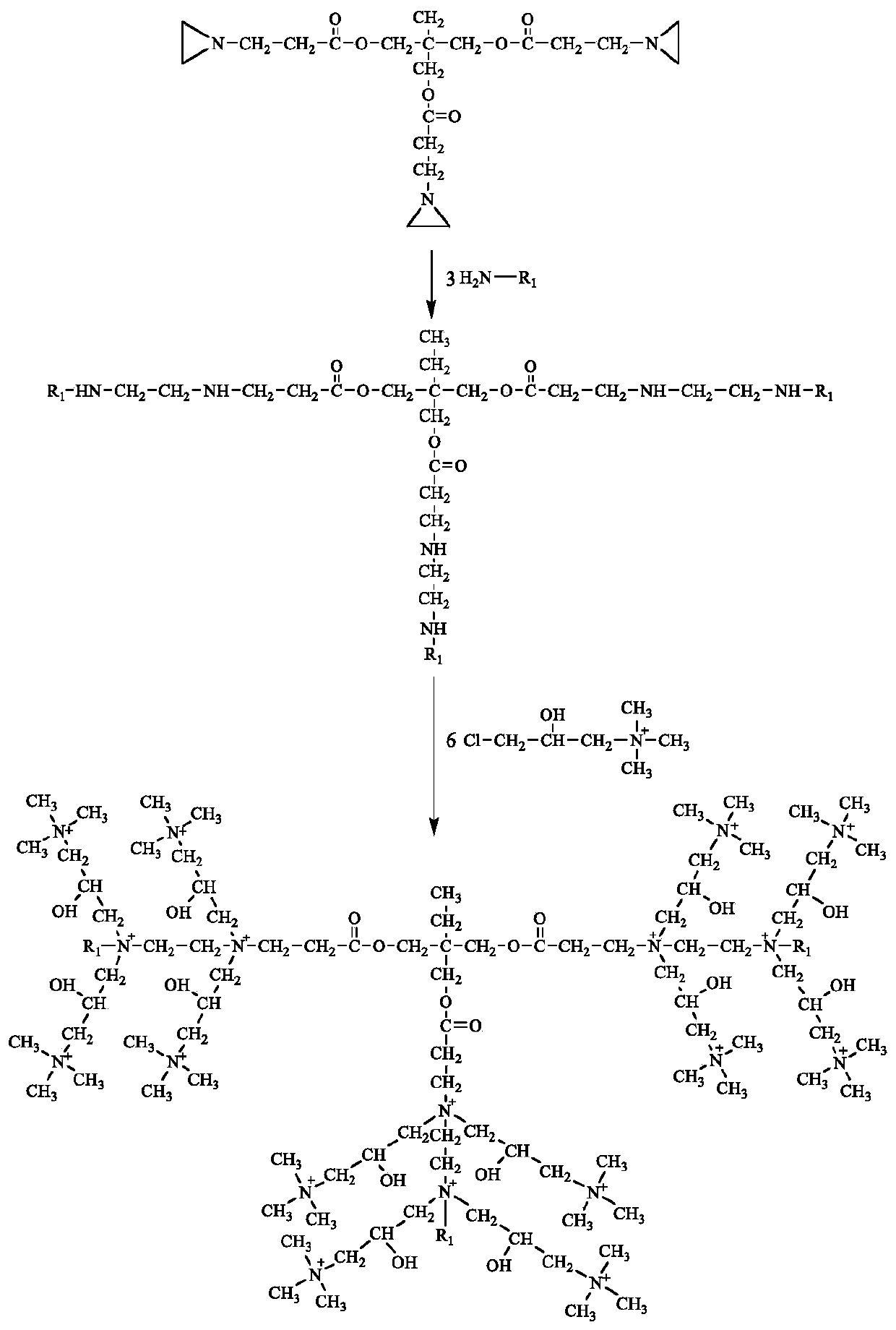

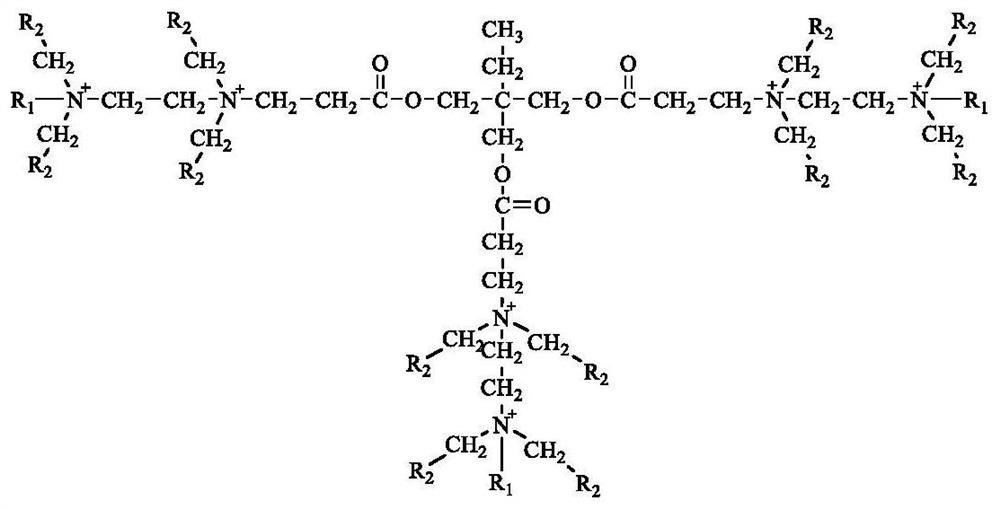

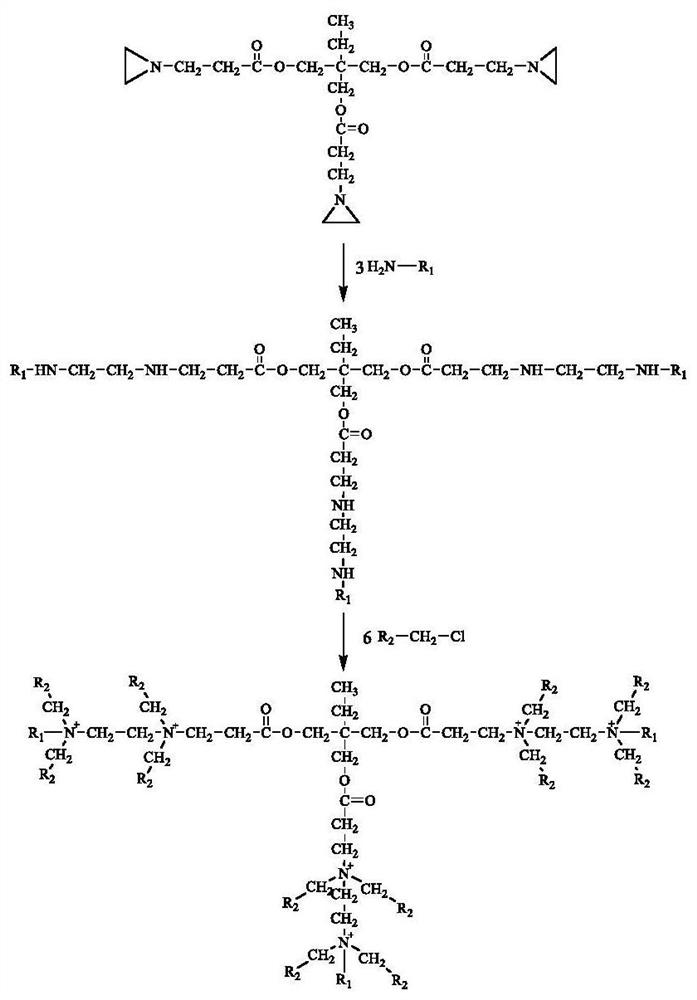

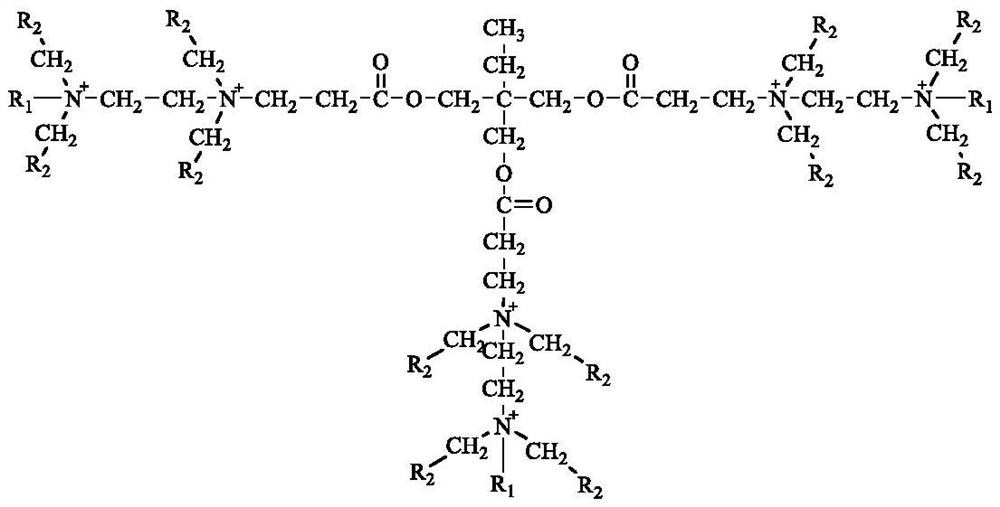

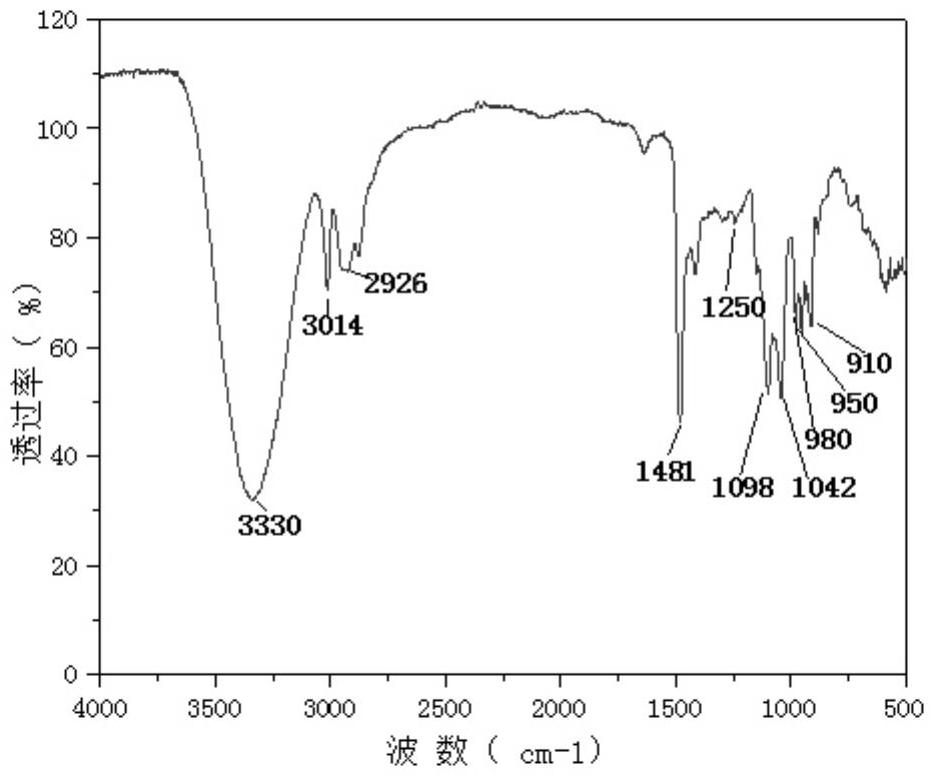

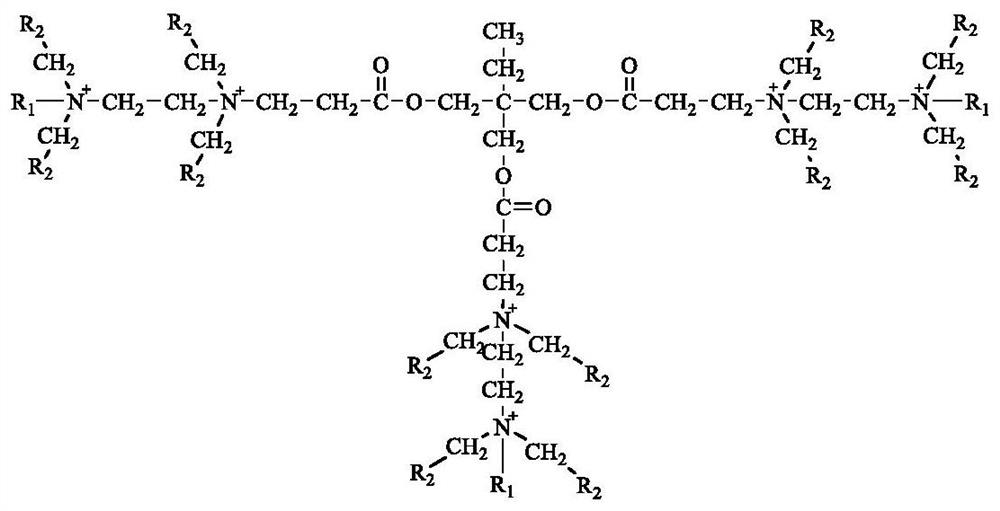

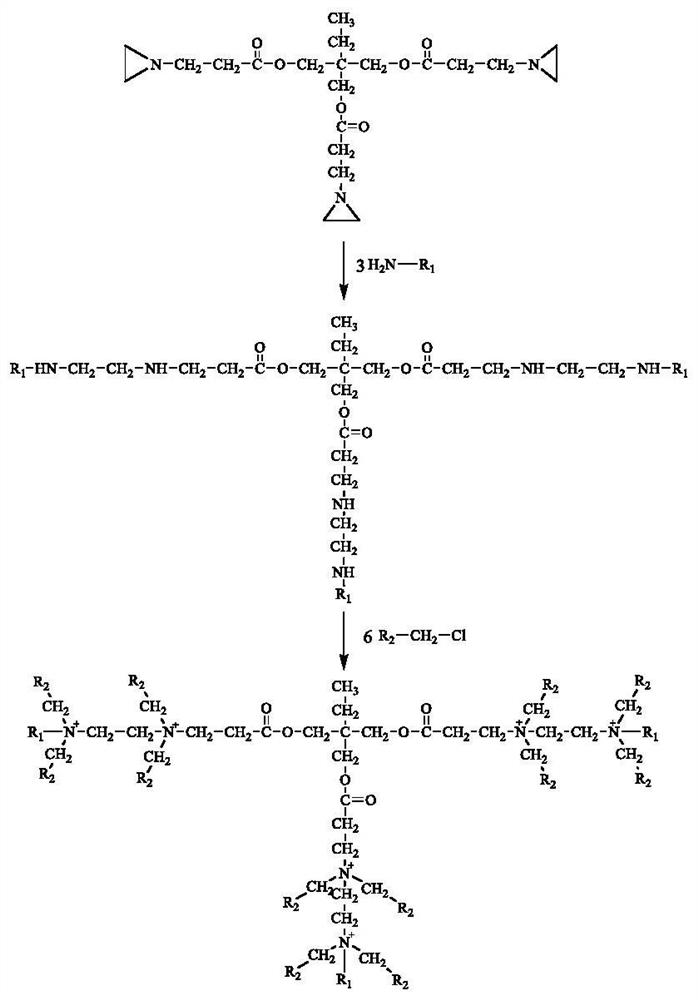

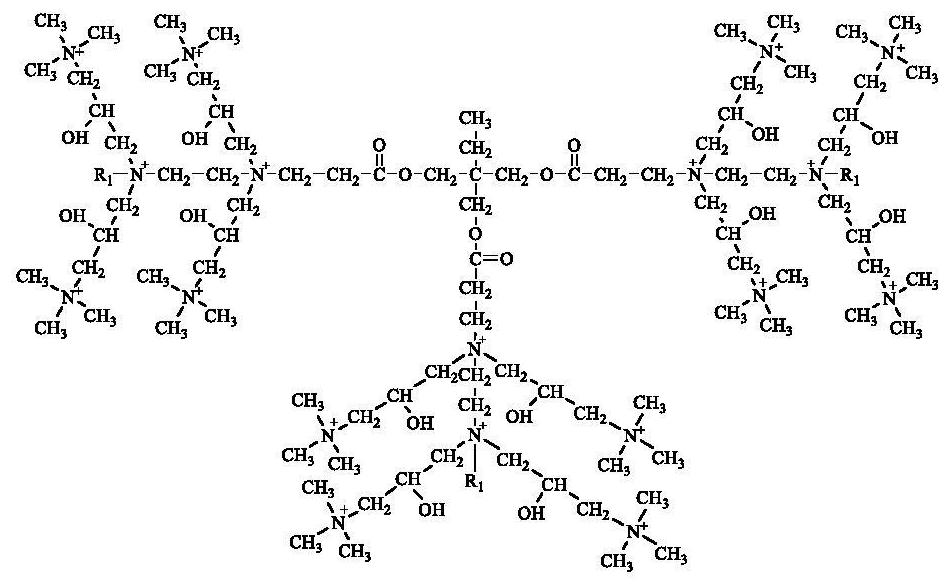

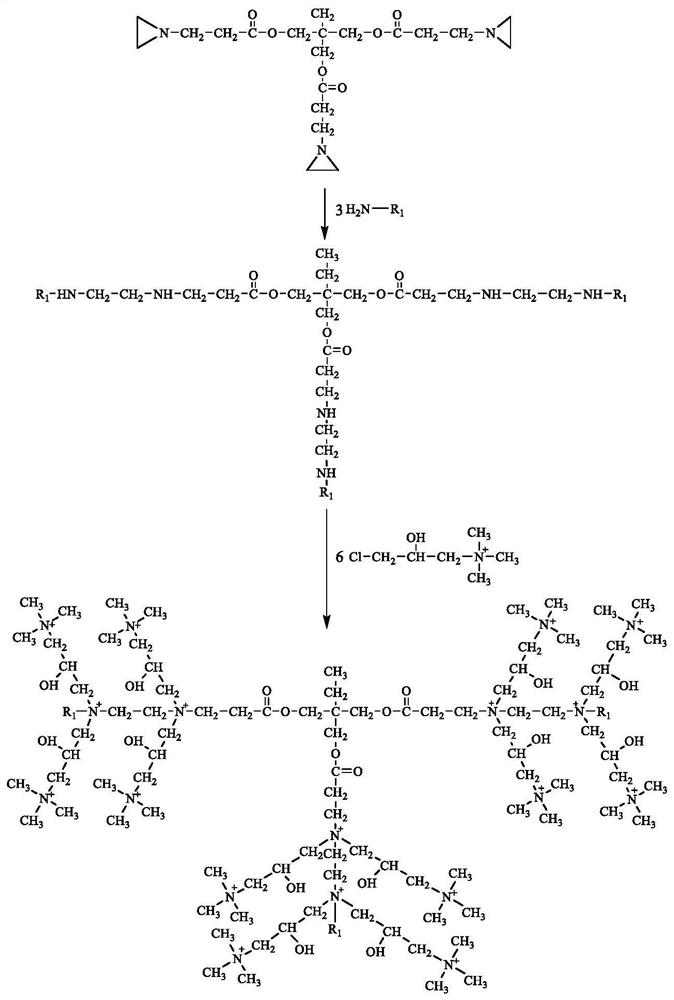

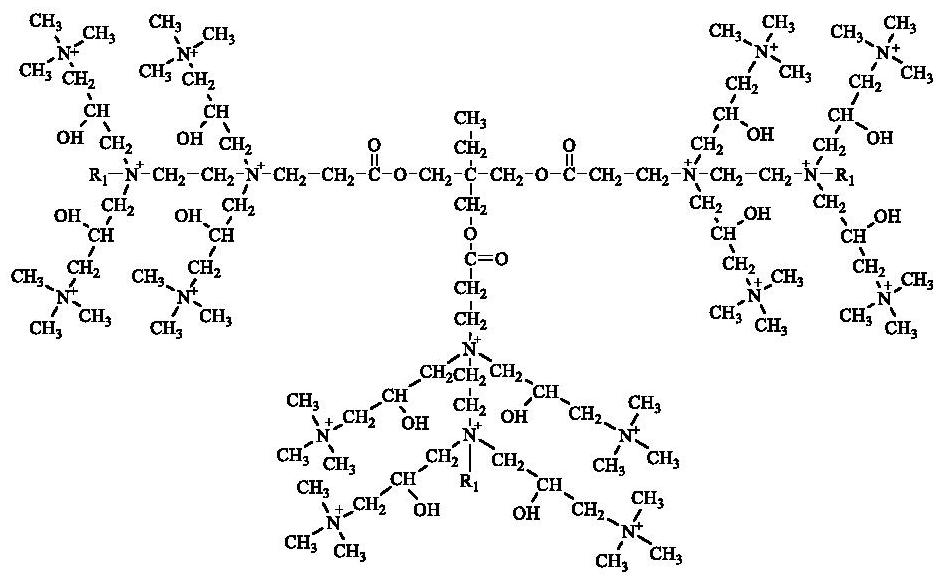

Star-shaped polycation-based surfactant as well as preparation method and application thereof

ActiveCN108440323AWide range of actionInhibits hydration swellingOrganic compound preparationAmino-carboxyl compound preparationAziridineBenzyl chloride

The invention discloses a star-shaped polycation-based surfactant as well as a preparation method and application thereof. The surfactant is prepared through the following steps: dropwise adding a certain amount of a trimethylol propane-tri(3-aziridinylpropanoate) reaction solution into a reaction flask filled with a long-chain fatty primary amine ethanol solution and an acidic catalyst, and carrying out first-step aziridine ring-opening reaction; then adding a certain amount of a chloromethane (or benzyl chloride) reaction solution into a reaction solution and carrying out second-step amination reaction, wherein the obtained product is the star-shaped polycation-based surfactant.

Owner:KENTE CATALYSTS INC

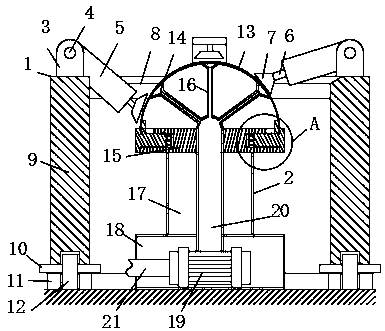

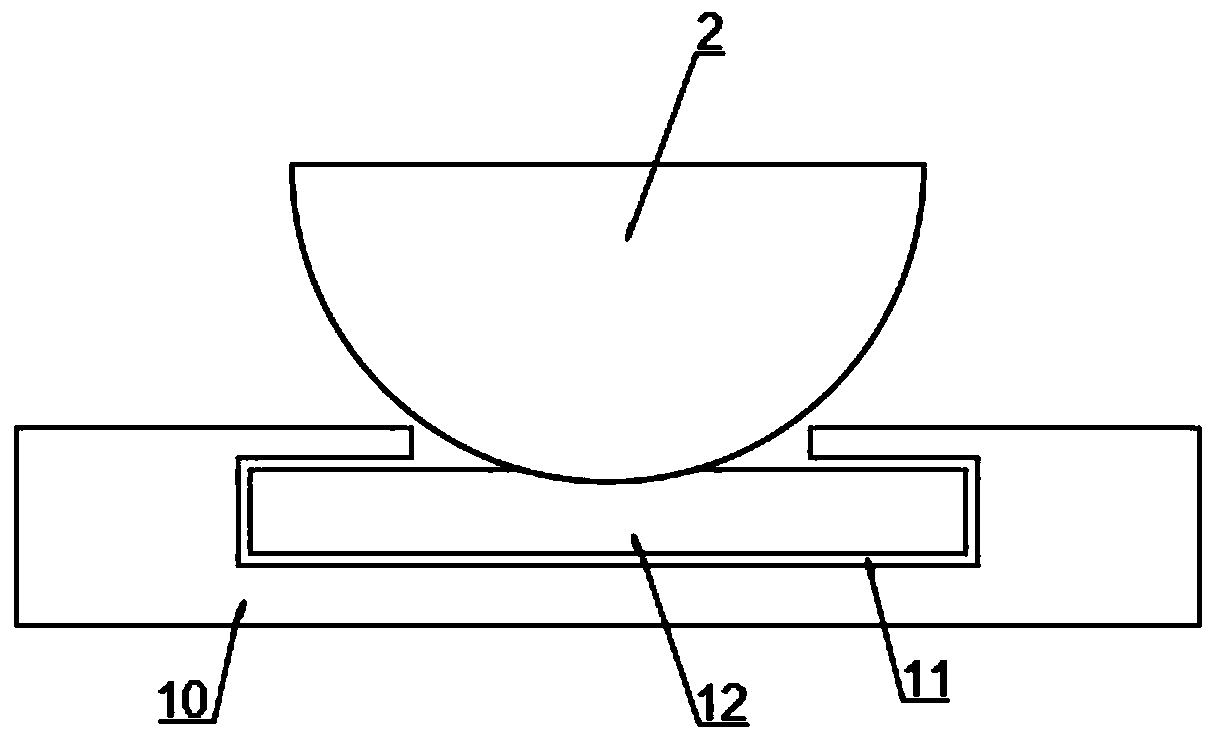

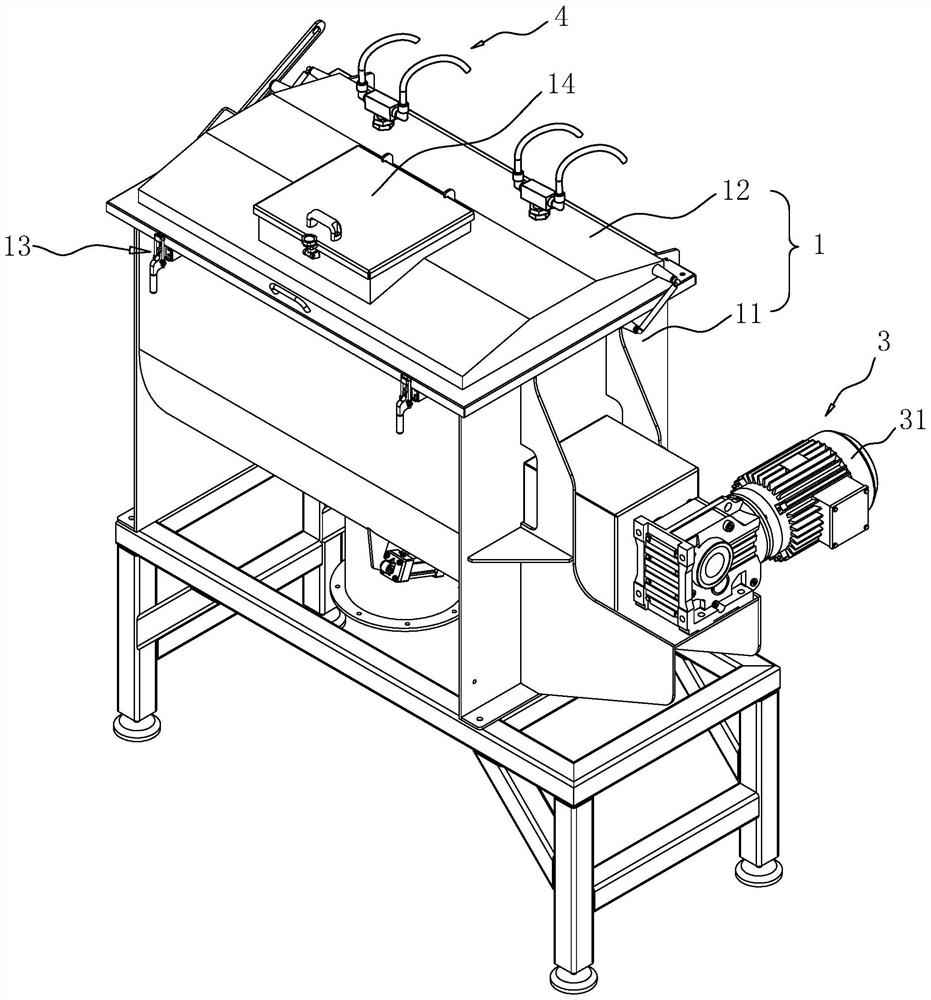

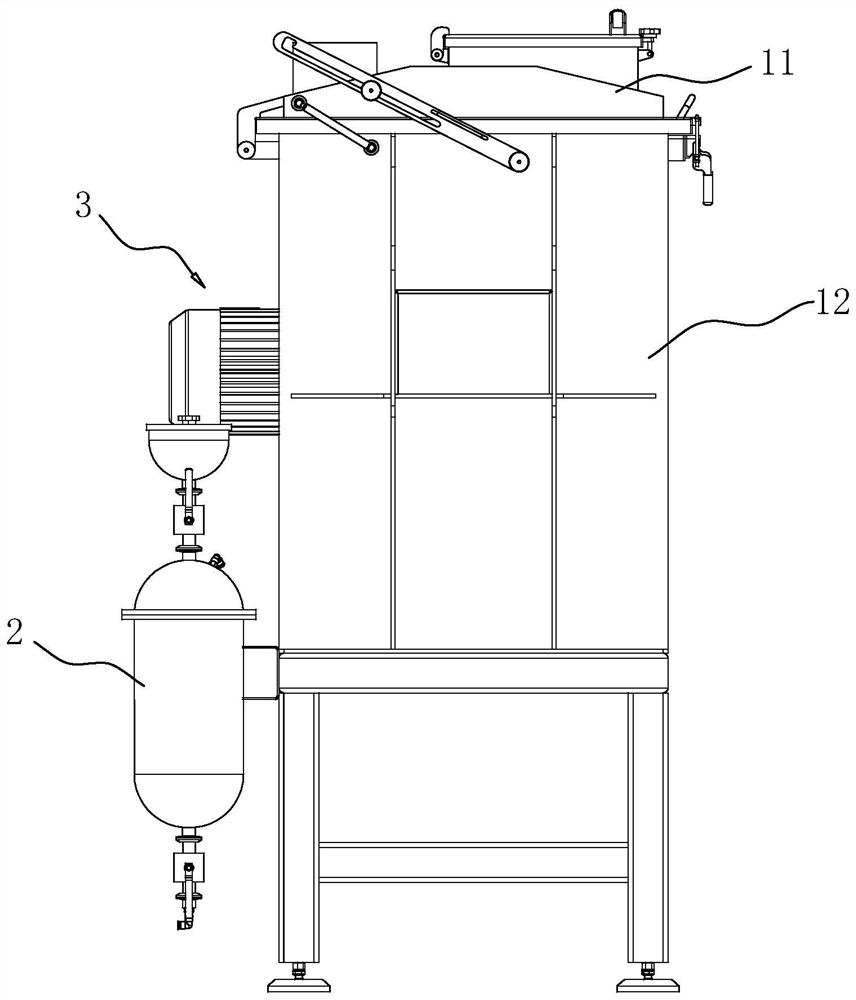

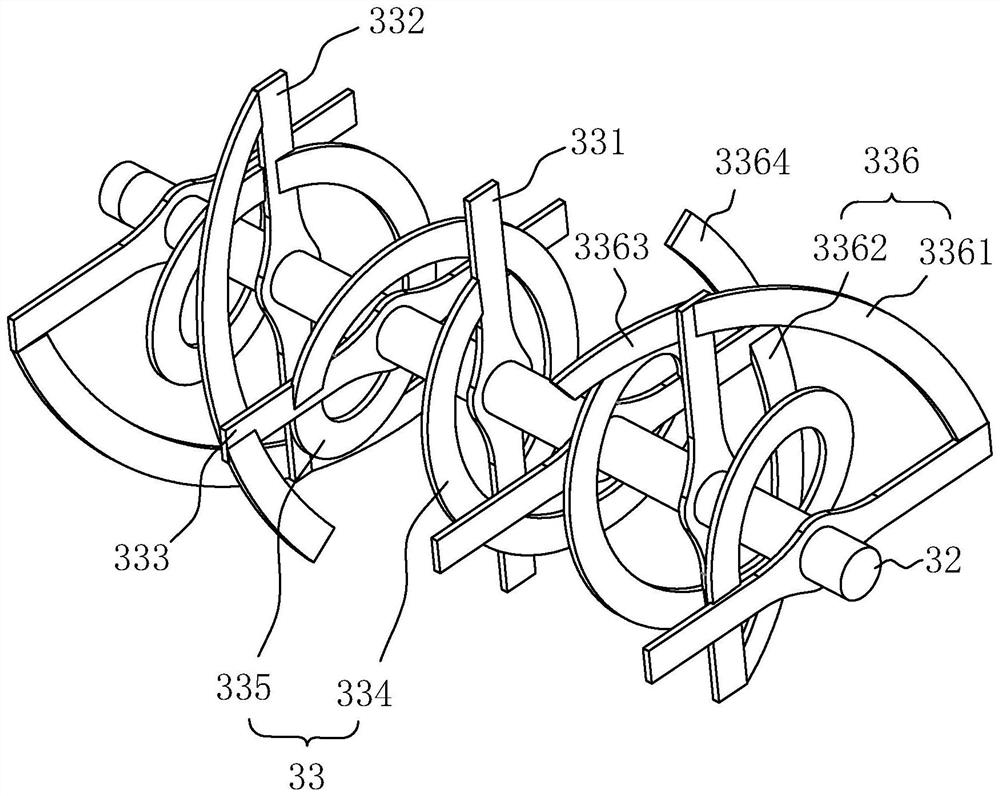

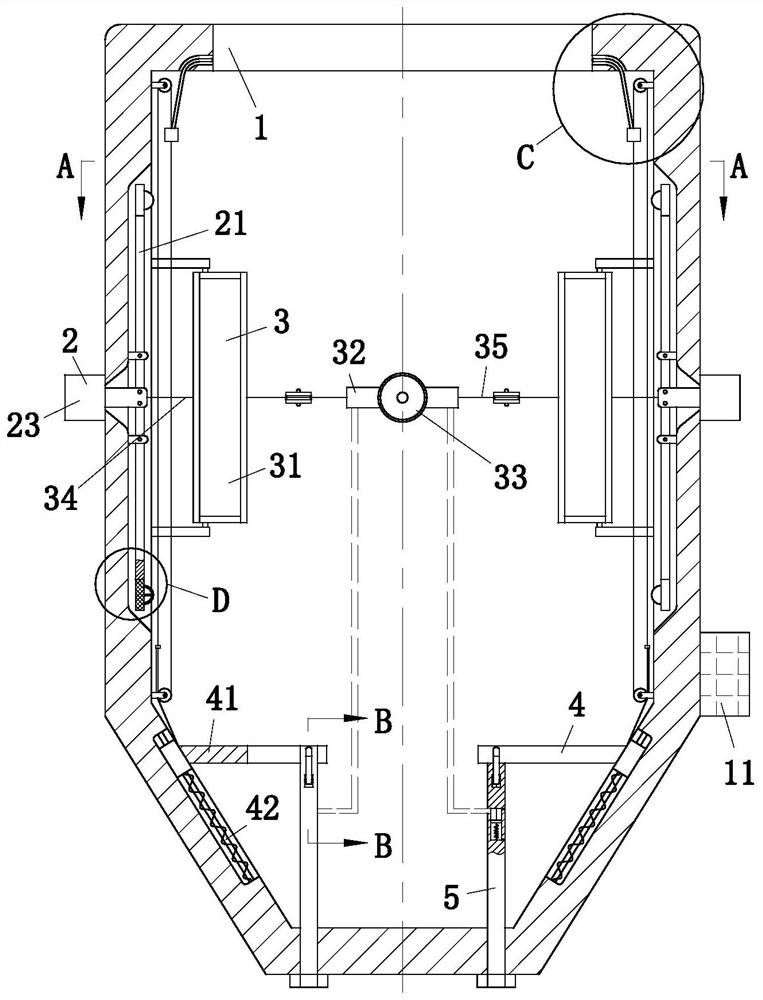

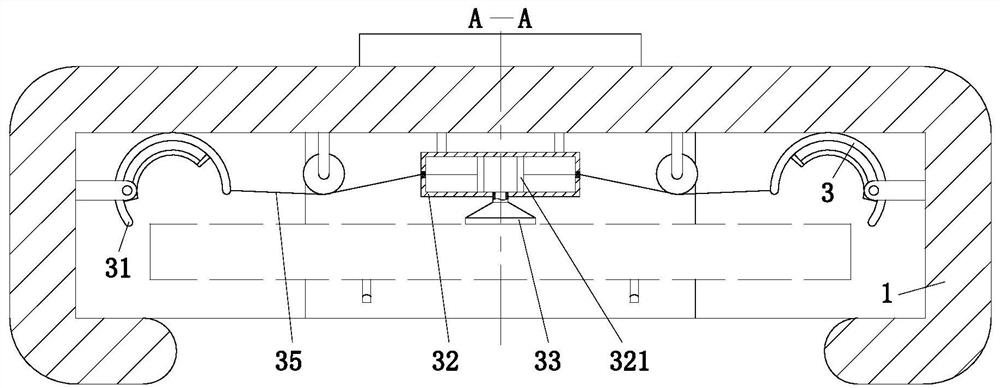

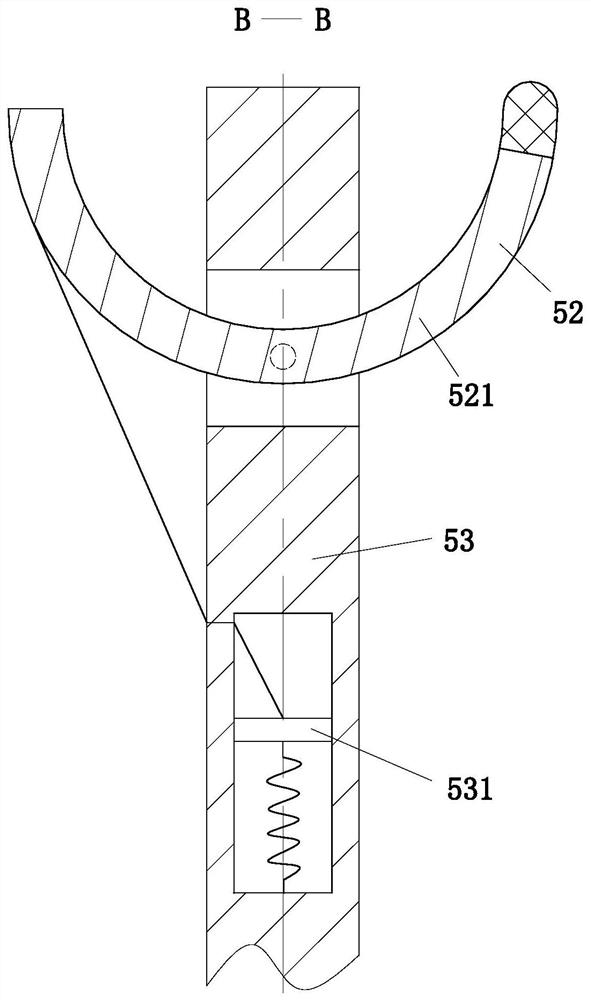

High-temperature high-pressure jig dyeing device for cotton cloth production and processing

InactiveCN110205765ARealize the role of swingAvoid sediment accumulationLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsElectric machineryCotton cloth

The invention belongs to the technical field of cotton cloth production and processing, particularly relates to a high-temperature high-pressure jig dyeing device for cotton cloth production and processing and aims to solve the problems of dye accumulation and precipitation, low temperature pressure intensity and poor adorptivity of dye in existing jig dyeing processes. The jig dyeing device comprises a mounting tank and a container positioned in the mounting tank, the container is composed of a semicircular tank positioned at the lower end and an upper cover positioned at the upper end and matched with the semicircular tank, dye is arranged in the semicircular tank, a cloth winding roller and a cloth unwinding roller are mounted on the inner wall of the semicircular tank, two cloth discharging rollers positioned on the lower sides of the cloth winding roller and the cloth unwinding roller are fixed inside the semicircular tank, and a first motor is fixed on the outer wall of the semicircular tank. Shaking of the dye is realized by driving the container to move back and forth and a stirring rod to rotate in the process of jig dyeing, so that dye accumulation and precipitation are avoided; by heating pressure increase, adsorption efficiency of the dye is improved, and jig dyeing quality is better.

Owner:江苏科沃纺织股份有限公司

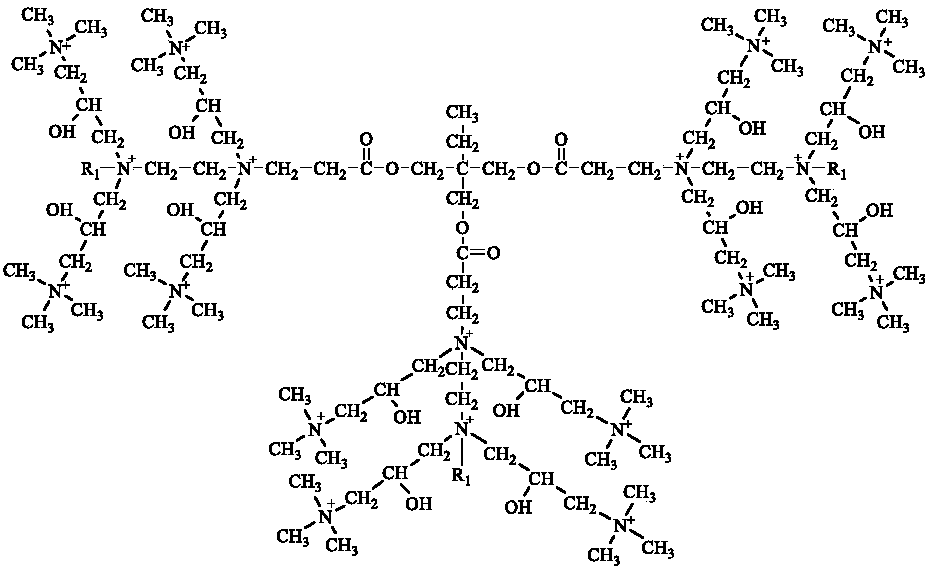

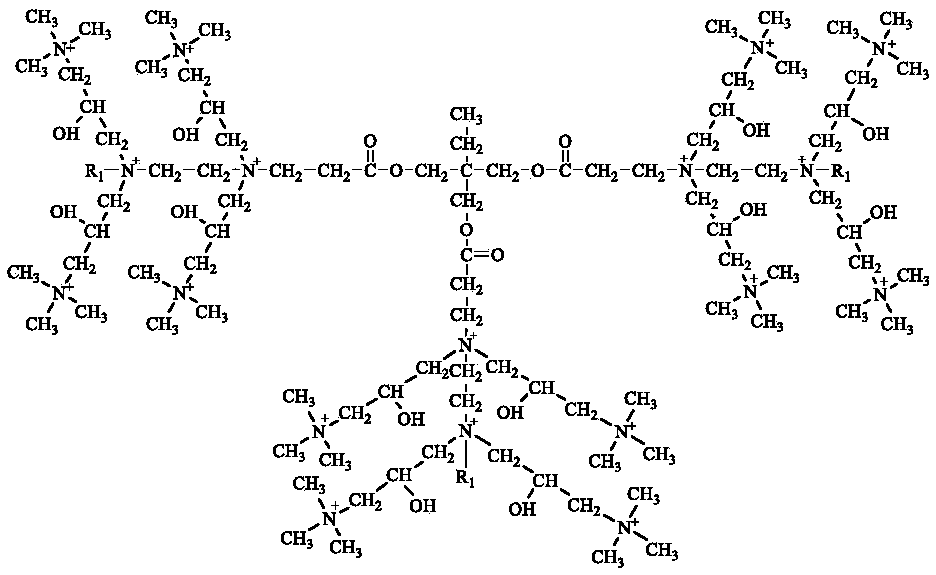

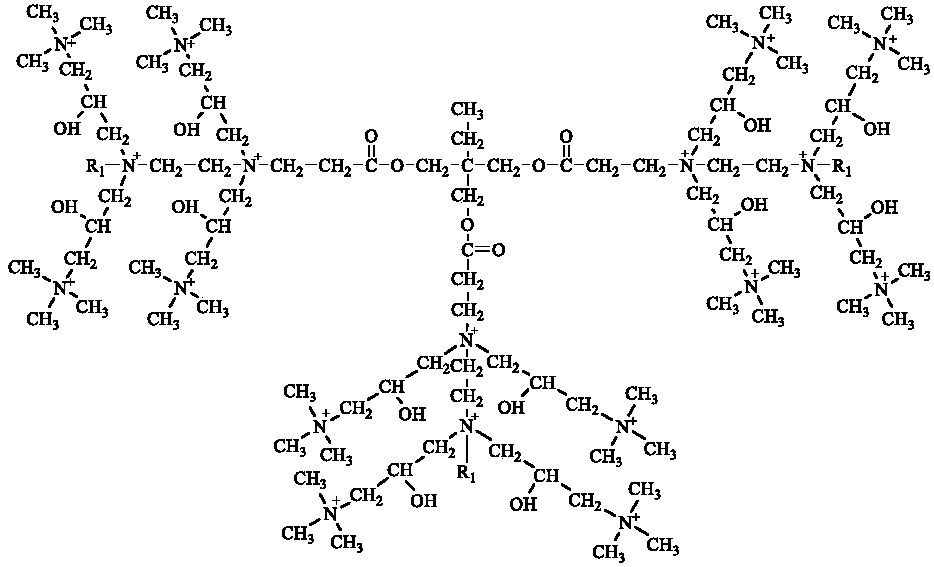

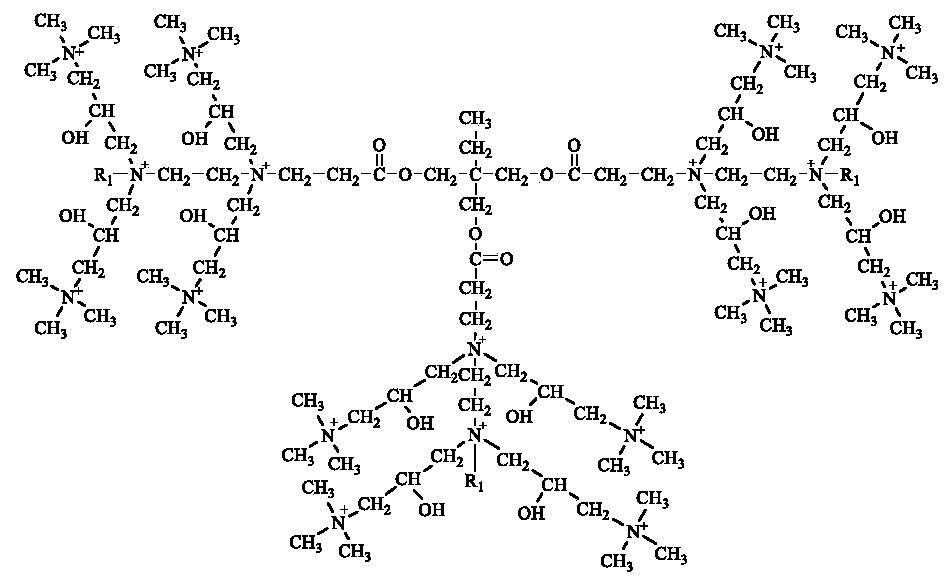

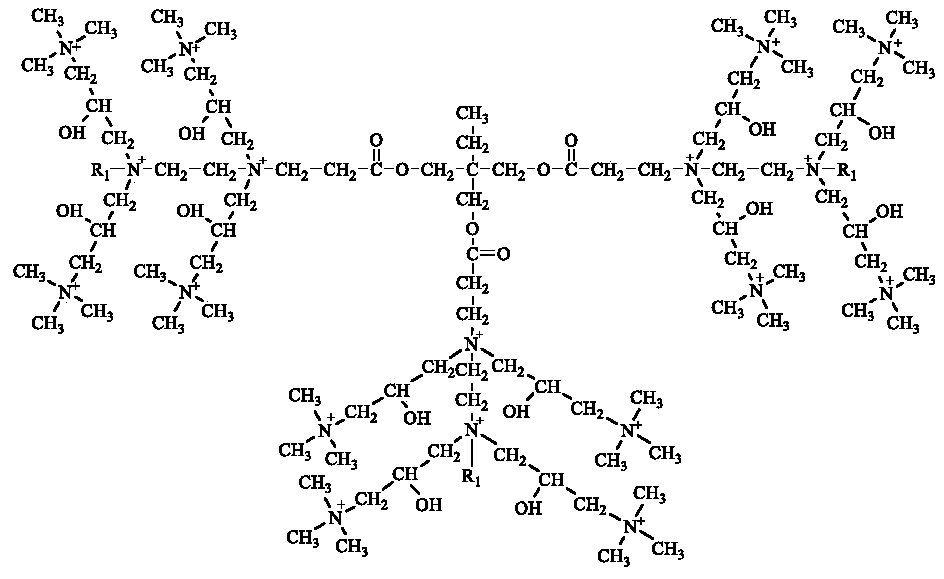

Star compound carrying intensive charge and preparation method thereof

ActiveCN108558691AHigh activityInhibit dyeing and finishingOrganic compound preparationAmino-carboxyl compound preparationPropionateChemical compound

The invention discloses a star compound carrying intensive charge and a preparation method thereof. The star compound is prepared according to the following steps: dropwise adding a certain amount oftrimethylolpropane-tris(3-aziridinyl propionate) reaction liquid into a reaction flask filled with a methylamine (or ethylamine) aqueous solution and an acid catalyst, so as to perform a first step ofan aziridine ring-opening reaction; then adding a certain amount of 3-chlorine-2-hydroxypropyl-trimethyl ammonium chloride into the reaction liquid, so as to perform a second step of a quarter of amination reaction. An obtained product is the star compound carrying the intensive charge.

Owner:SHAANXI UNIV OF SCI & TECH

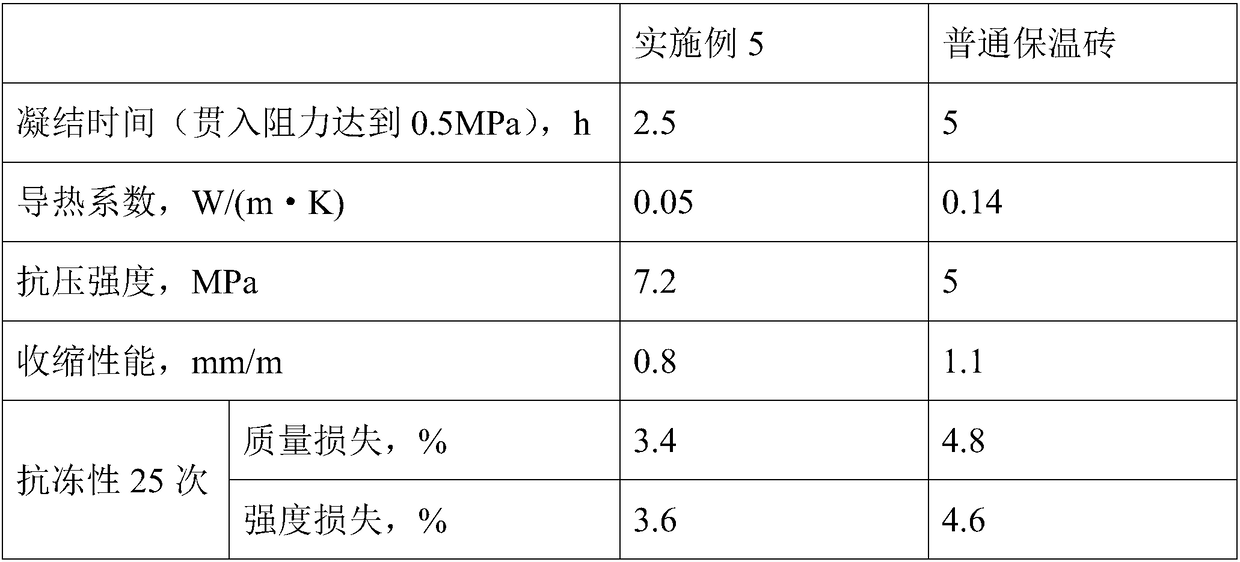

Method for preparing heat-insulation bricks with high compressive strength

The invention discloses a method for preparing heat-insulation bricks with high compressive strength. The method includes steps of adding corncob powder into potassium hydroxide solution, heating andstirring the corncob powder and the potassium hydroxide solution to obtain first mixtures, filtering the first mixtures, carrying vacuum drying on the first mixtures, carbonizing and grinding the first mixtures, adding humic acid and water into the first mixtures to obtain second mixtures, ultrasonically dispersing the second mixtures, filtering the second mixtures, carrying out vacuum drying on the second mixtures and smashing the second mixtures to obtain prefabricated materials; mixing building garbage, the prefabricated materials, mica powder, blast furnace slag, hydroxyethyl celluloses, diatomaceous earth, acrylonitrile base carbon fibers, sepiolite powder, grit, triethanolamine, sodium bicarbonate, ethylene-vinyl acetate copolymers, cement, heavy calcium carbonate and calcium chloride with one another to obtain third mixtures; smashing the third mixtures; adding the third mixtures into water and stirring the third mixtures and the water; carrying out press forming; carrying out natural still standing; carrying out normal-pressure curing to obtain the heat-insulation bricks with the high compressive strength. The method has the advantages that the heat-insulation bricks prepared by the aid of the method are high in compressive strength and difficult to craze, and have low heat conductivity coefficients, and good heat-insulation effects can be realized by the heat-insulation bricks.

Owner:安徽润晟建设有限公司

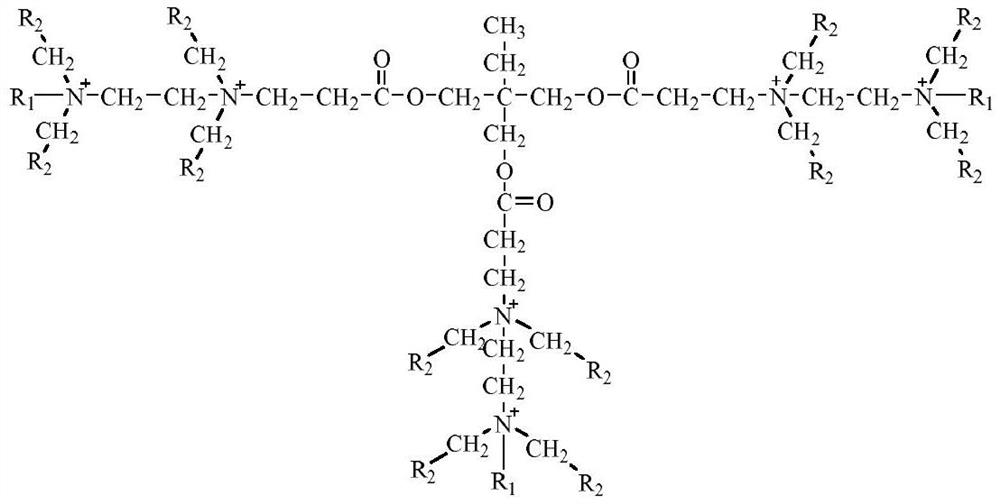

Cationic surfactant with dense charges and preparation method and applications thereof

ActiveCN108543498AHigh surface/interface activityLow critical micelle concentrationOrganic compound preparationTransportation and packagingAmmonium chloride mixturePropionate

The invention discloses a cationic surfactant with dense charges and a preparation method and applications thereof. The surfactant is prepared by the following steps: dropwise adding quantitative trihydroxymethyl propane-tri(3-aziridinyl propionate) reaction liquid into a reaction bottle, which is filled with an ethanol solution of long chain aliphatic primary amine and an acidic catalyst to carryout aziridine ring-opening reactions (first step); and then adding quantitative 3-chloro-2-hydroxypropyl-trimethyl ammonium chloride into the reaction liquid to carry out quaternary amination reactions (second step). The reaction product is the cationic surfactant with dense charges.

Owner:KENTE CATALYSTS INC

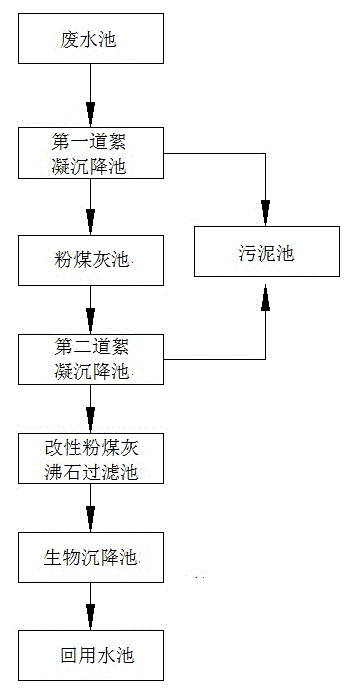

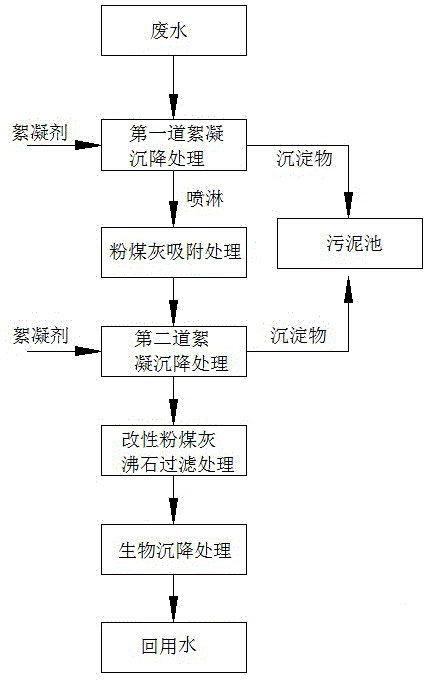

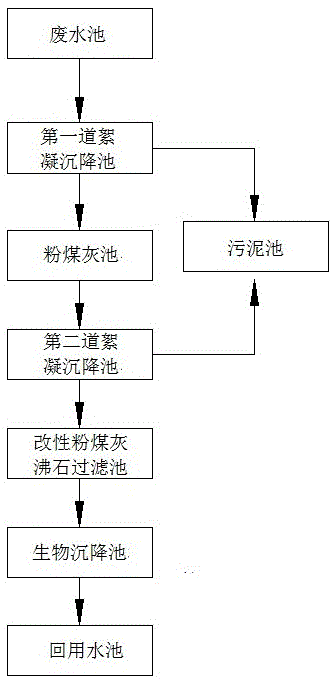

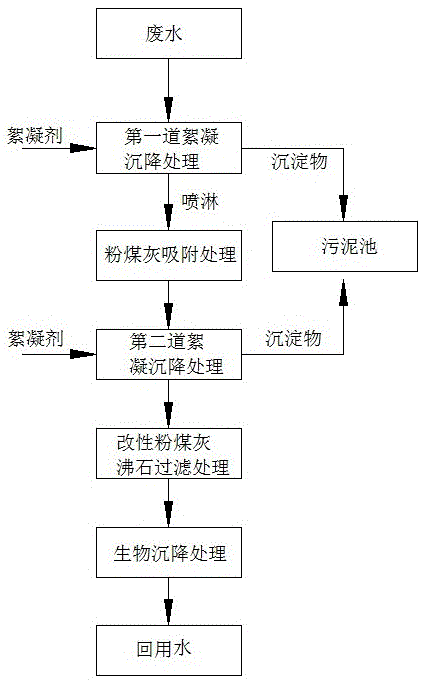

Papermaking wastewater treatment system and method

ActiveCN104370412AGood purification effectShorten the timeMultistage water/sewage treatmentWaste water treatment from plant processingSettlingZeolite

The invention relates to a papermaking wastewater treatment system and method. The wastewater treatment system comprises a wastewater tank, a first flocculating settling tank, a fly ash tank, a second flocculating settling tank, a modified fly ash zeolite filtration tank, a biological settling tank and a reuse water tank. The wastewater treatment method comprises the following steps: first flocculating settling, fly ash adsorption roguing, second flocculating settling, modified fly ash zeolite adsorption filtration and biological settlement. The system and method can gradually remove harmful substances in the wastewater, and have the advantages of ideal purifying effect and short wastewater treatment period.

Owner:安徽景丰纸业有限公司

Bio-oxidization-method harmless treatment technology of arsenic-containing dangerous wastes

The invention provides a bio-oxidization-method harmless treatment technology of arsenic-containing dangerous wastes. The bio-oxidization-method harmless treatment technology comprises the following steps: carrying out oxidization on arsenic-containing wastes; adding the oxidized arsenic-containing waste into a three-dimensional aeration tank; adding activated sludge into the three-dimensional aeration tank; matching the three-dimensional aeration tank with a mains supply driving motor through intercepted wind power to drive a stirring device and a gas feeding mechanism to stir the arsenic-containing wastes and the activated sludge in the aeration tank; after separating the activated sludge and clarified water, overflowing and discharging the clarified water, wherein the activated sludge is increased continuously in a treatment process and residual sludge in a sedimentation tank is discharged. According to the bio-oxidization-method harmless treatment technology, arsenic ions of the arsenic-containing wastes are adsorbed through the activated sludge so that the pollution, caused by the arsenic-containing wastes, on the environment is solved; a wind power direct driving manner is matched with a unique structure of the aeration tank, so that the function of the aeration tank is finished under the condition that electric energy is not needed or less electric energy is needed and secondary pollution to thermal power is reduced.

Owner:许立中

A bio-oxidation harmless treatment process for arsenic-containing hazardous waste

The invention provides a harmless treatment process of arsenic-containing hazardous waste biological oxidation method, which includes the following steps: oxidizing arsenic-containing waste; putting the oxidized arsenic-containing waste into a three-dimensional aeration tank, adding active Sludge; the three-dimensional aeration tank drives the stirring device and the air intake mechanism to stir the arsenic-containing waste and activated sludge in the aeration tank by intercepting the wind force and the city electric drive motor; the fully aerated waste and activated sludge are sent to After entering the sedimentation tank, the activated sludge is separated from the clarified water, and the clarified water overflows and is discharged; during the treatment process, the activated sludge continues to grow, and the remaining sludge is removed in the sedimentation tank. The invention uses activated sludge to absorb arsenic ions in arsenic-containing waste to solve the environmental pollution of arsenic-containing hazardous waste, and is directly driven by wind to cooperate with the unique structure of the aeration tank, without the need for electric energy or a small amount of electric energy Complete the function of the aeration tank and reduce the secondary pollution of thermal power.

Owner:许立中

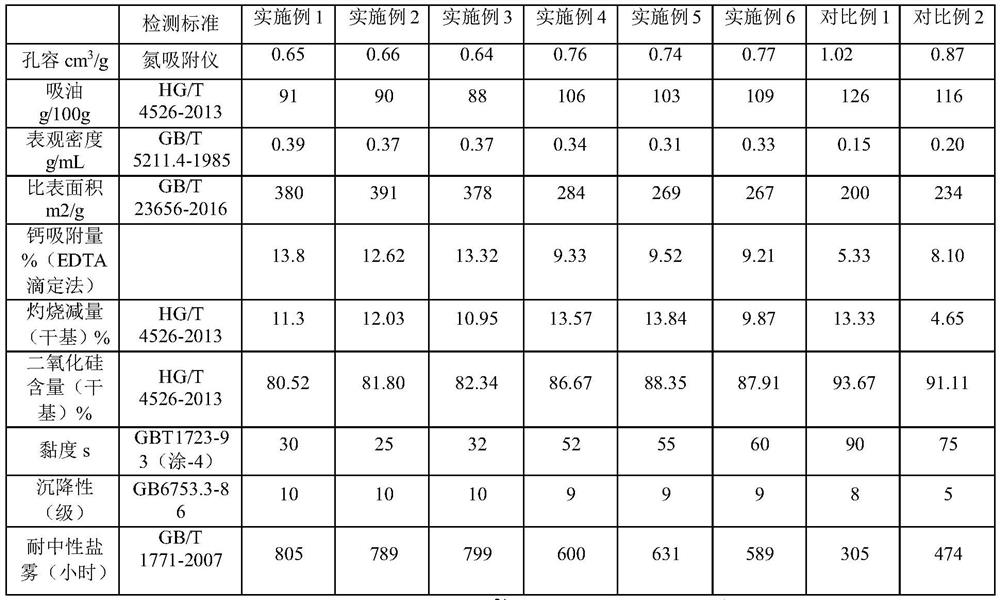

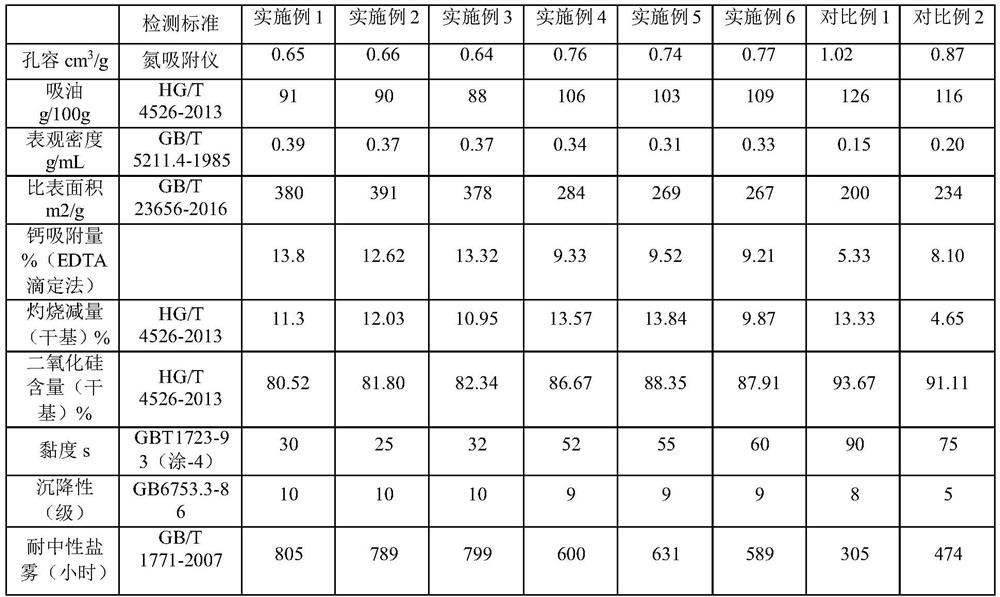

Composite anticorrosive pigment and preparation method and application thereof

InactiveCN112175432AReduce oil absorptionLow pore volumeAnti-corrosive paintsEpoxy resin coatingsO-Phosphoric AcidIon exchange

The invention discloses a composite anticorrosive pigment and a preparation method and application thereof, and belongs to the field of pigments, which comprises the following steps: reacting sodium silicate and sulfuric acid used as raw materials at normal temperature and normal pressure to synthesize low-water-pore low-oil-absorption silicon dioxide, sequentially adding a supersaturated calciumhydroxide solution, a phosphoric acid solution and calcium chloride into the system, uniformly stirring and mixing to obtain the composite anticorrosive pigment, coating with a wax emulsion, washing,drying and crushing to obtain the anticorrosive pigment with the average particle size of less than 5[mu]m. According to the preparation method, the whole process is normal temperature and normal pressure, a single anti-corrosion mechanism is broken through, design is comprehensively considered from the aspects of compact layer forming, calcium ion exchange and metal chelating, the production costis low, and the prepared anti-corrosion pigment is excellent in salt mist resistance. The main component of the anticorrosive pigment is low-water-pore low-oil-absorption silicon dioxide, the main component of the anticorrosive pigment is calcium phosphate, oxidized polyethylene wax and adsorbed calcium ions, the salt spray resistance is achieved by forming a compact layer, chelating phosphoric acid ions and exchanging part of calcium ions, and the salt spray resistance is excellent.

Owner:北京航天赛德科技发展有限公司

Preparation method and application of composite anticorrosive coating

ActiveCN112251063AReduce oil absorptionLow pore volumeAnti-corrosive paintsEpoxy resin coatingsEpoxyO-Phosphoric Acid

The invention discloses a preparation method and application of a composite anticorrosive paint, and belongs to the field of pigments. The preparation method comprises the following steps: 1) preparing a composite anticorrosive pigment: taking sodium silicate and sulfuric acid as raw materials, and reacting at normal temperature and normal pressure to synthesize low-water-pore low-oil-absorption silicon dioxide, sequentially adding a supersaturated calcium hydroxide solution, a phosphoric acid solution and calcium chloride into the system, uniformly stirring and mixing the mixture, coating themixture with a wax emulsion, washing and drying the mixture, and crushing the mixture to obtain the anticorrosive pigment with the average particle size of less than 5 [mu]m; 2) mixing 65-75 parts byweight of epoxy resin, 12-15 parts by weight of butyl acetate, 8-12 parts by weight of a composite anticorrosive pigment, 5.5 parts by weight of a drying agent and 0.5 part by weight of iron oxide red to prepare the anticorrosive paint. The whole process of the preparation method is carried out at normal temperature and normal pressure, wherein a single anti-corrosion mechanism is broken through,design is comprehensively considered from the aspects of compact layer forming, calcium ion exchange and metal chelating, the production cost is low, and the prepared anti-corrosion pigment is excellent in salt mist resistance.

Owner:北京航天赛德科技发展有限公司

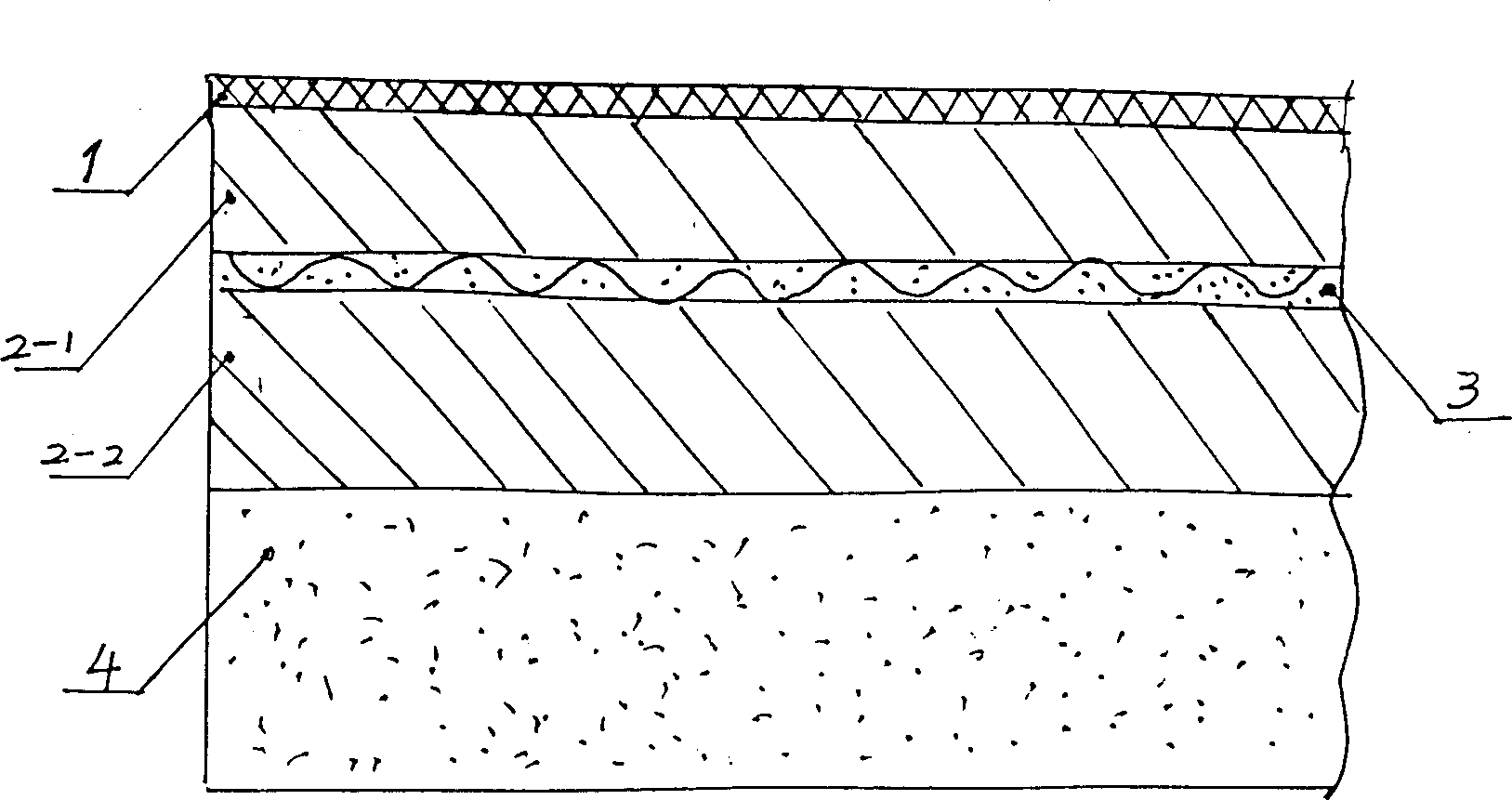

Lining material for garbage burying field

InactiveCN1124204CEffectively interceptEffective immobilizationProtective foundationNatural mineral layered productsSodium BentoniteHalocarbon

The lining material for garbage-burying field features by blending the organic, metal and natural bentonites together to construct the laminar lining material. The invented material has strong absorption ability to the organic pollutants such as carbolic acid, aniline, benzol series material and halocarbon containing in the percolating liquid of the garbage so that it can prevent the leakage of organic pollutants so as to protect underground water from pollution.

Owner:鲁安怀

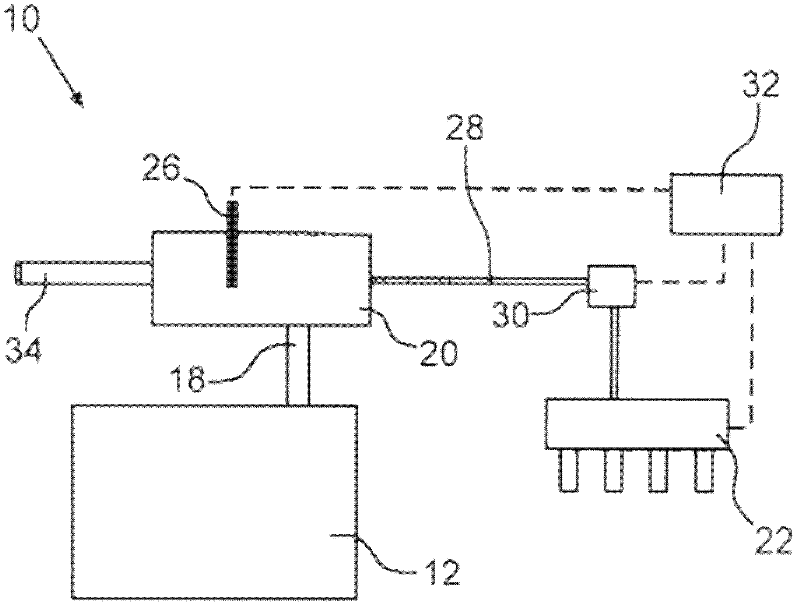

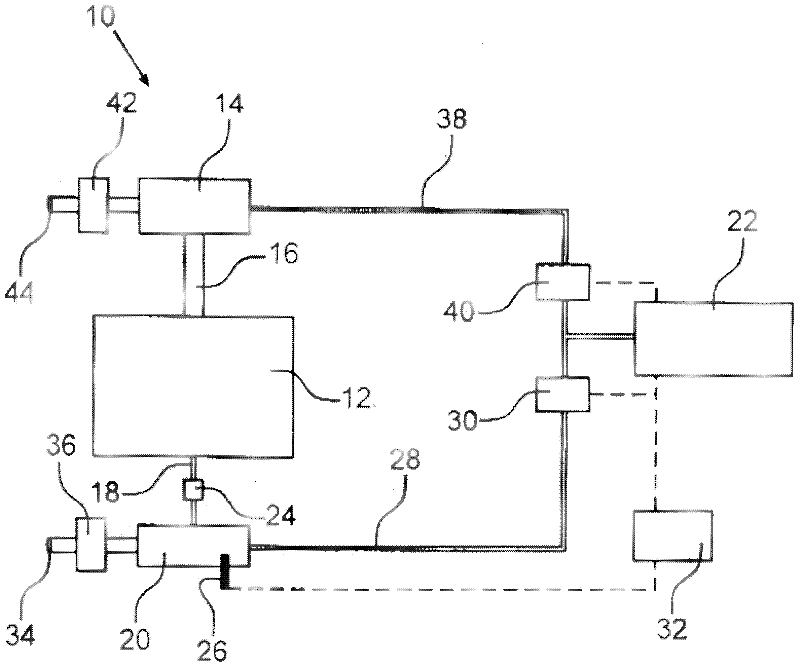

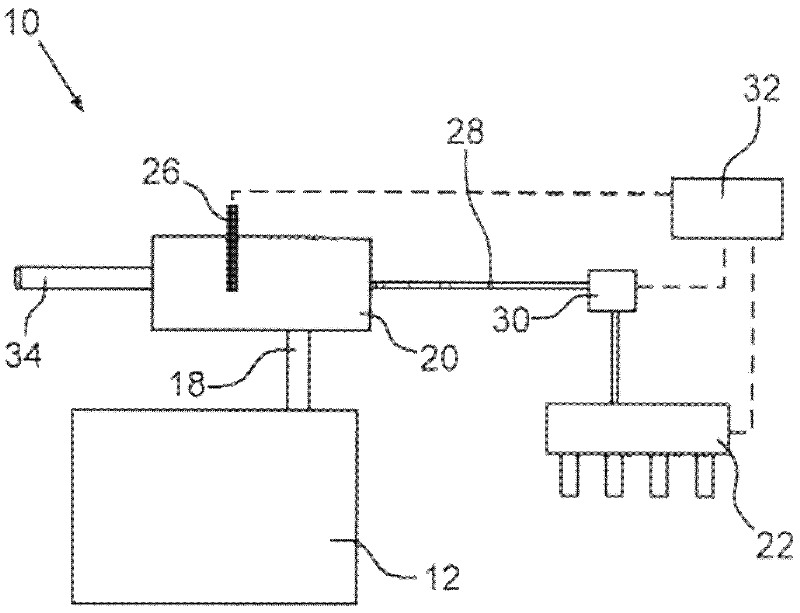

Ventilating device used for fuel tank and method used for operating ventilating device

InactiveCN102330622AImprove the degree of adsorptionTimely responseHybrid vehiclesElectrical controlCombustionFuel tank

The present invention relates to a ventilating device (10) used for a fuel tank (12) of a motor vehicle, wherein the ventilating device (10) comprises: at least one filter (20) used for storing and releasing gaseous hydrocarbon from the fuel tank (12); a detection device (26) used for detecting adsorption degree of the gaseous hydrocarbon of the at least one filter (20); and a control device (32) which is designed to start a combustion engine (22) of the motor vehicle in order to make the at least one filter (20, 20') regenerate, thereby preventing the gaseous hydrocarbon from escaping from the ventilating device (10) unhopefully. In addition, the present invention also relates to a method for operating the ventilating device (10) used for the fuel tank (12) of the motor vehicle.

Owner:AUDI AG

A kind of cationic surfactant carrying intensive charge and its preparation method and application

ActiveCN108543498BHigh surface/interface activityLow critical micelle concentrationOrganic compound preparationTransportation and packagingPropionatePolymer science

The invention discloses a cationic surfactant carrying a dense charge and its preparation method and application. The surfactant is prepared through the following steps: adding quantitative The trimethylolpropane-three (3-aziridinyl propionate) reaction solution carries out the first step aziridine ring-opening reaction; then in the reaction solution, add quantitative 3-chloro-2-hydroxypropyl- Trimethylammonium chloride is subjected to the second step of quaternization reaction, and the resulting product is a cationic surfactant carrying a dense charge.

Owner:KENTE CATALYSTS INC

A star-shaped polycation-based compound and its preparation method and application

ActiveCN108546235BImprove the degree of adsorptionHigh anti-expansion rateOrganic compound preparationTransportation and packagingPropanoic acidActive agent

Owner:KENTE CATALYSTS INC

A kind of clay stabilizer and its application

ActiveCN107312507BImprove the degree of adsorptionImprove the degree of reaction conversionDrilling compositionFatty amineEngineering

Owner:CHINA PETROLEUM & CHEM CORP +1

A papermaking wastewater treatment system and method

ActiveCN104370412BImprove purification effectShorten cycle timeMultistage water/sewage treatmentWaste water treatment from plant processingWater treatment systemFiltration

The invention relates to a papermaking wastewater treatment system and method. The wastewater treatment system includes a wastewater tank, a first flocculation sedimentation tank, a fly ash tank, a second flocculation sedimentation tank, a modified fly ash zeolite filter tank, and a biological A settling tank and a reuse pool; the wastewater treatment method includes the first step of flocculation and settlement, fly ash adsorption to remove impurities, the second step of flocculation settlement, modified fly ash zeolite adsorption and filtration and biological settlement steps. The invention removes harmful substances in waste water step by step, has ideal purification effect and short waste water treatment cycle.

Owner:安徽景丰纸业有限公司

Seasoning tea and production method and production equipment thereof

PendingCN114468083AStrong aromaComprehensive adsorptionPre-extraction tea treatmentRotary stirring mixersBiotechnologyPropylene glycol

The invention relates to the field of seasoning tea, and particularly discloses seasoning tea and a production method and production equipment of the seasoning tea. The seasoning tea comprises the following raw material components in parts by weight: 90-98 parts of tea leaves and 2-10 parts of edible essence, propylene glycol accounting for 3%-8% of the mass of the edible essence is also added into the seasoning tea; the preparation method comprises the following steps: S1, heating and drying the tea leaves; s2, spraying edible essence which is half of the mass of the edible essence required in the seasoning tea onto the tea leaves, and rolling and mixing at the residual temperature in the step S1; s3, repeating the steps S1 and S2 once; s4, performing heat preservation on the tea leaves treated in the step S3 at 40-45 DEG C for 10-20 minutes, and cooling the tea leaves to 30-35 DEG C after heat preservation; and S5, performing closed spreading cooling on the tea leaves treated in the step S4, and finally packaging the tea leaves to obtain a finished product of the seasoning tea. The preparation method has the advantage of improving the aromatic flavor degree and the lasting degree of the seasoning tea.

Owner:杭州茗宝生物科技有限公司

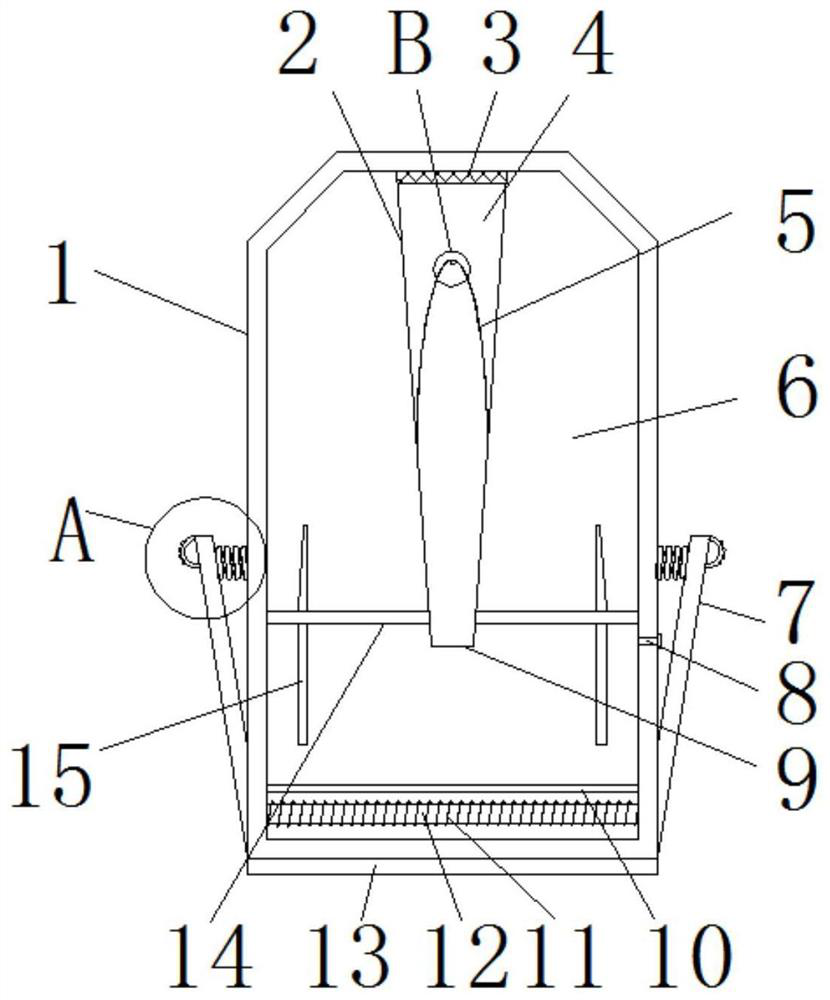

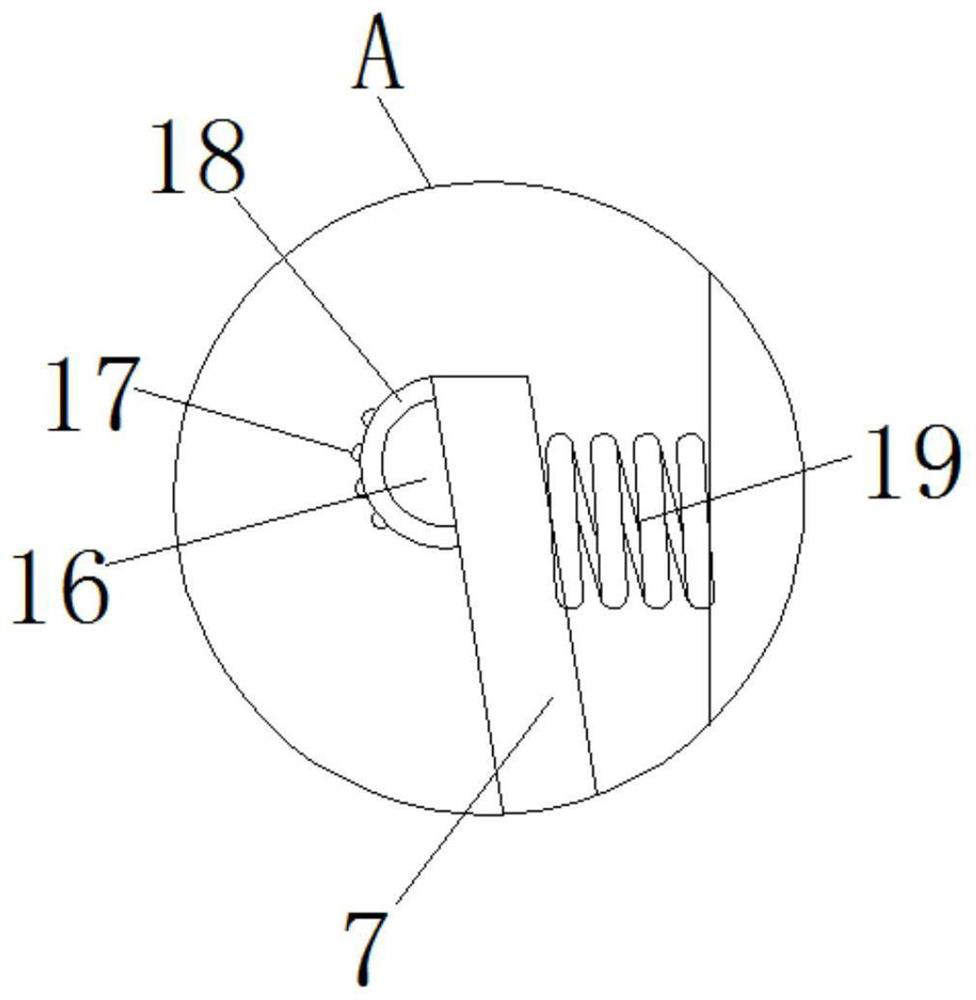

A mobile phone holder for a car

ActiveCN109733295BIncrease clamping speedImprove clamping efficiencyVehicle componentsControl theoryDistance sensors

The invention belongs to the technical field of mobile phone holders, and in particular relates to a mobile phone holder for an automobile. The mobile phone holder comprises a support frame, horizontal clamping modules, a fixing module, a supporting module and a vertical clamping module, wherein the horizontal clamping modules are mounted on the inner sides of two side walls of the support frame;the fixing module is arranged on the inner wall of the rear side of the support frame and between the two horizontal clamping modules; the supporting module is mounted at the bottom of the support frame; the vertical clamping module is arranged on the support frame; the supporting module comprises sliding propping plates and guide rods; the horizontal clamping modules comprise electric push rods,clamping rods and adsorption units; the vertical clamping module comprises a top clamping unit, a bottom clamping unit and sliding columns; the top ends of the two sliding columns are both provided with distance sensors; and the top clamping unit and the bottom clamping unit are separately arranged on the top of the support frame and the sliding columns. The mobile phone holder for the automobiledetermines the width of a mobile phone according to the downward moving distance of the sliding columns, and clamps two sides of the mobile phone in a fitting manner, thereby improving the stability of the mobile phone and avoiding falling off and damage.

Owner:上海伟昊汽车技术股份有限公司

Pulling type atomization generating device

The invention discloses a pulling type atomization generating device which comprises a device body, oil storage bins and a heat conducting plate; a partition plate is arranged in the device body, a smoke outlet channel is formed in the partition plate, a leakage-proof elastic part and a filter plate are arranged in the smoke outlet channel, the filter plate is located above the leakage-proof elastic part, a smoke inlet hole is formed in the lower portion of the leakage-proof elastic part, and a clamping plate is arranged on the outer surface of the device body; and the oil storage bins are arranged in the device body and located on the left side and the right side of the smoke outlet channel. The heat conducting plate is arranged below the smoke outlet channel, the heat conducting plate is communicated with the smoke outlet channel, a heating rod is arranged below the heat conducting plate, an electric heating wire is arranged outside the heating rod, and an electromagnet is arranged below the heating rod; and smoke can be filtered through the filter plate, the taste of the smoke is guaranteed, it is avoided that tar is secondarily absorbed by the human body again to cause greater damage and affect the use taste, and the device body can be arranged on the electronic cigarette in a drawable mode through the electromagnet and the clamping plate.

Owner:洛阳市保盈电子科技有限公司

Preparation method of high-strength thermal insulation material

The invention belongs to the technical field of building material preparation, and particularly relates to a preparation method of a high-strength thermal insulation material. The preparation method comprises the following steps: firstly, grinding and mixing vermiculite and montmorillonite, then putting the obtained mixture into an ethylene glycol solution after the grinding, mixing to prepare a dispersion, dropwise adding an alkali liquor into the dispersion, heating and stirring at high temperature to obtain an alkaline reaction solution, adding ramie into the alkaline reaction solution, carrying out oil bath heating treatment, adding acetic acid, mixing to obtain a to-be-reacted solution, adding ammonium persulfate for reaction, reacting at high temperature and high pressure to obtain aheat treatment product, performing suction filtration on the heat treatment product, washing, performing high-temperature sintering to prepare a modified thermal insulation agent, mixing the modifiedthermal insulation agent, stearic acid and other materials, performing hot pressing, freezing, soaking in acetone, and drying to obtain the high-strength thermal insulation material. The thermal insulation material prepared through the method is good in thermal insulation performance, good in mechanical strength and not prone to deformation and damage and has wide application prospects.

Owner:泉州市鼎鑫丰泰建筑材料科技有限公司

A kind of star polycation-based surfactant and its preparation method and application

ActiveCN108440323BWide range of actionInhibits hydration swellingOrganic compound preparationAmino-carboxyl compound preparationPropanoic acidPtru catalyst

The invention discloses a star-shaped polycation-based surfactant as well as a preparation method and application thereof. The surfactant is prepared through the following steps: dropwise adding a certain amount of a trimethylol propane-tri(3-aziridinylpropanoate) reaction solution into a reaction flask filled with a long-chain fatty primary amine ethanol solution and an acidic catalyst, and carrying out first-step aziridine ring-opening reaction; then adding a certain amount of a chloromethane (or benzyl chloride) reaction solution into a reaction solution and carrying out second-step amination reaction, wherein the obtained product is the star-shaped polycation-based surfactant.

Owner:KENTE CATALYSTS INC

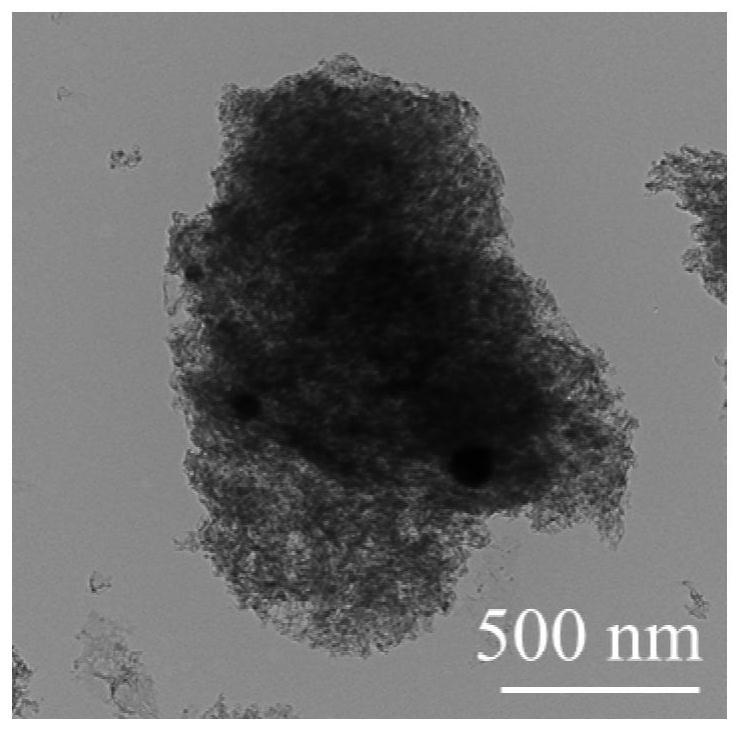

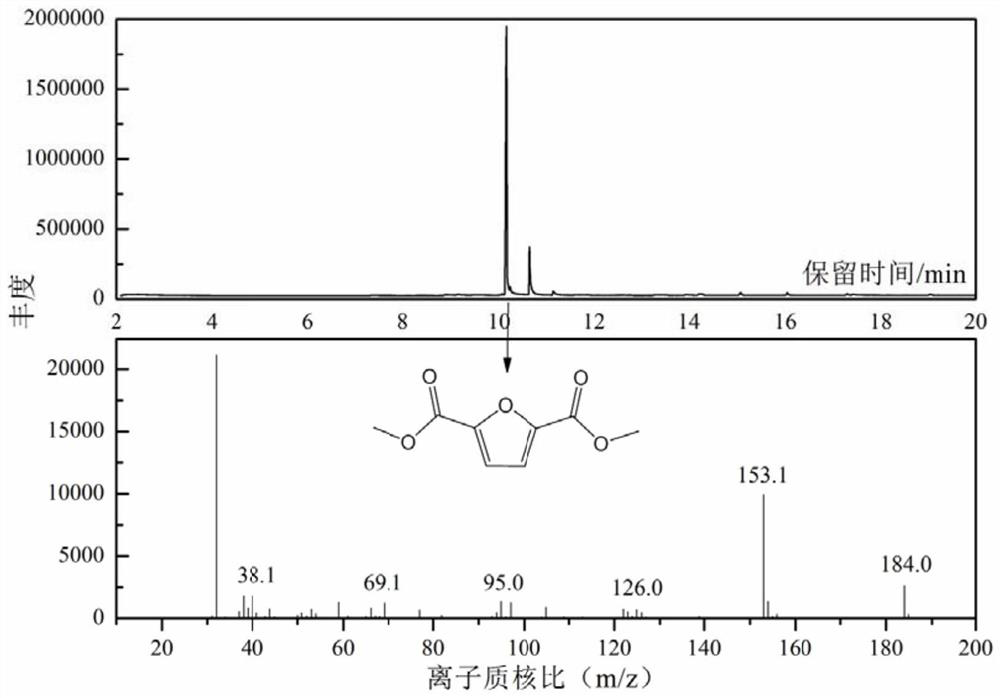

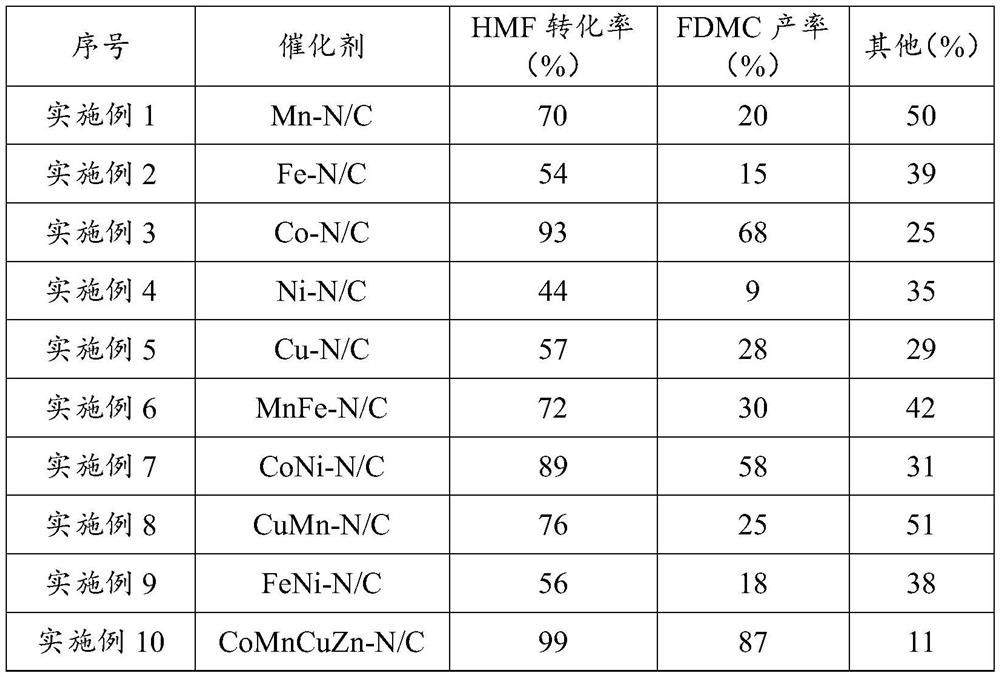

Method for preparing dimethyl furan-2,5-dicarboxylate

InactiveCN112979596AAvoid pollutionReduce manufacturing costOrganic chemistryCatalyst activation/preparationFuranPtru catalyst

The invention discloses a method for preparing dimethyl 2,5-furandicarboxylate. The method comprises the following step: in an oxidizing atmosphere, carrying out catalytic oxidation on 5-hydroxymethylfurfural in the presence of a non-noble metal catalyst to prepare the dimethyl 2,5-furandicarboxylate, wherein the non-noble metal catalyst comprises a nitrogen-containing carrier and a non-noble metal active component loaded on the nitrogen-containing carrier. According to the method, no extra alkaline additive is needed, pollution is small, the use of a noble metal catalyst is avoided, the preparation cost of the dimethyl furan-2,5-dicarboxylate is reduced, a process is simple, and the method is suitable for wide industrial application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of star compound with dense charge and its preparation method

ActiveCN108558691BHigh activityInhibit dyeing and finishingOrganic compound preparationAmino-carboxyl compound preparationPropanoic acidPtru catalyst

The invention discloses a star compound carrying intensive charge and a preparation method thereof. The star compound is prepared according to the following steps: dropwise adding a certain amount oftrimethylolpropane-tris(3-aziridinyl propionate) reaction liquid into a reaction flask filled with a methylamine (or ethylamine) aqueous solution and an acid catalyst, so as to perform a first step ofan aziridine ring-opening reaction; then adding a certain amount of 3-chlorine-2-hydroxypropyl-trimethyl ammonium chloride into the reaction liquid, so as to perform a second step of a quarter of amination reaction. An obtained product is the star compound carrying the intensive charge.

Owner:SHAANXI UNIV OF SCI & TECH

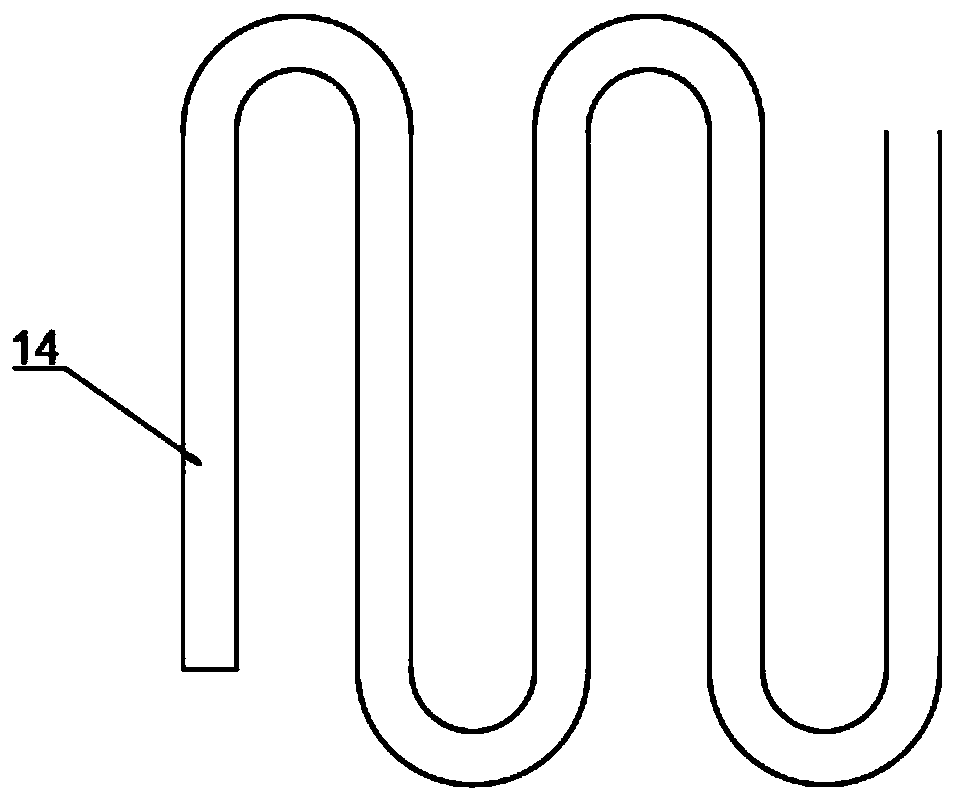

Rolling adsorption type sludge harmless treatment method

InactiveCN108178468AImprove the degree of adsorptionEasy to drySludge treatmentActivated carbonSludge

The invention discloses a rolling adsorption type sludge harmless treatment method. The rolling adsorption type sludge harmless treatment method comprises the following steps of S1, dissolving sludgeinto water, fully stirring, heating, standing after heating is finished, and finally filtering out the floating matter; S2, pouring the filtered sludge into a precipitation tank to precipitate, pouring out a supernatant liquid, uniformly spraying the precipitated sludge water onto a high temperature-resistant sponge, heating the high temperature-resistant sponge, and stopping heating after the sludge on the high temperature-resistant sponge is dried; S3, sending the high temperature-resistant sponge containing the dried sludge into a vibrator, collecting the vibrated-out sludge powder, sendingthe high temperature-resistant sponge into an air blower, blowing out a small amount of residual sludge powder, and collecting; S4, sequentially performing rolling adsorption on the collected sludgepowder by an activated carbon roll, spraying a sodium citrate solution to complex, stirring the sludge in a spraying tank, and filtering the sludge solution after reaction to separate out the heavy metal complex. The rolling adsorption type sludge harmless treatment method has the advantage that the harmless treatment degree is high.

Owner:中运建设控股有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com