Clay stabilizer and applications thereof

A clay stabilizer and reaction technology, which is applied in the field of clay stabilizer preparation, can solve the problems of high molecular weight, formation damage, and low anti-swelling rate of polymer clay stabilizers, and achieve inhibition of hydration expansion, dispersion migration, and anti-swelling. The effect of high expansion rate and high degree of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 1.2 mol of trimethylamine into a three-necked flask, add 10 mol of distilled water under stirring conditions, slowly add 0.5 mol of epichlorohydrin dropwise through a constant pressure dropping funnel, control acceleration to keep the temperature below 20°C, and keep warm for 1 hour after dropping; Add 0.5mol epichlorohydrin, gradually raise the temperature to 90-95°C and react for 2 hours; then add 0.4mol triethylenetetramine, add 0.5mol epichlorohydrin dropwise, raise the temperature to 65-70°C and react for 2 hours, and the product is vacuum-dried Get clay stabilizers.

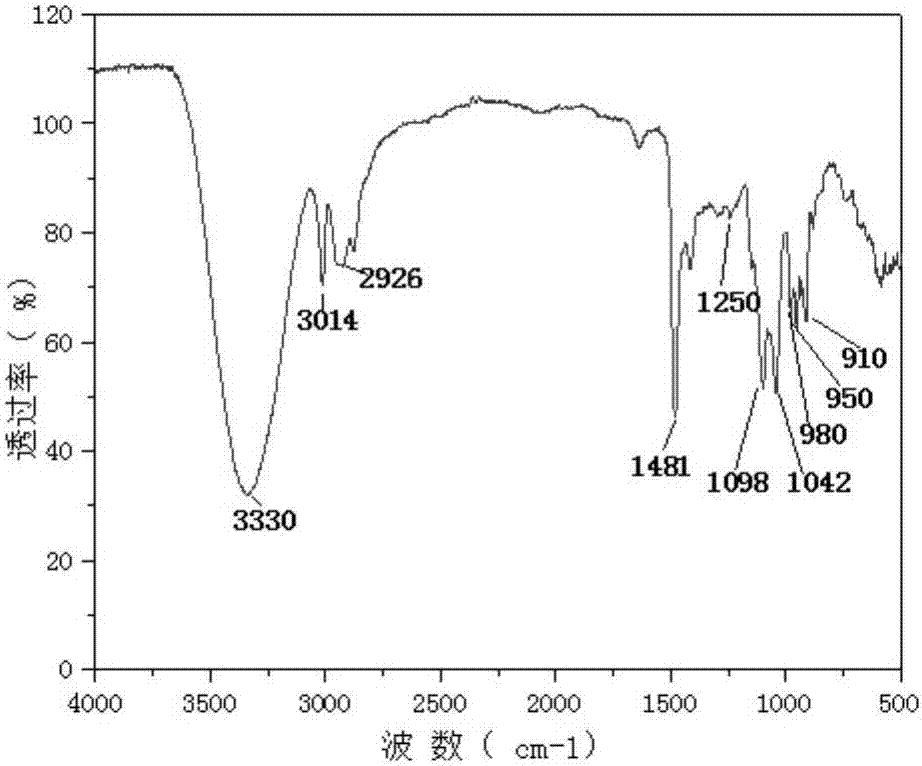

[0027] Infrared characterization of the clay stabilizer was carried out by figure 1 It can be seen that 1250cm -1 、980cm -1 It is the characteristic absorption peak of C-N, 2900~3000cm -1 It is the C-H stretching vibration peak in methyl and methylene, and there is no N-H absorption peak in this figure, 3330cm -1 The hydroxyl peak at place is the characteristic peak of water after the potassi...

Embodiment 2

[0030] Add 1.2 mol of dimethylamine into the three-necked flask, add 10 mol of distilled water under stirring conditions, slowly add 0.4 mol of epichlorohydrin dropwise using a constant pressure dropping funnel, control the acceleration to keep the temperature below 20°C, and keep warm for 1 hour after the dropping is completed; then Then add 0.4mol epichlorohydrin, and gradually raise the temperature to 80-85°C for 2 hours; then add 0.4mol triethylenetetramine, add 0.4mol epichlorohydrin dropwise, raise the temperature to 65-70°C for 2 hours, and dry the product under vacuum Then get clay stabilizer.

[0031] After testing, the stabilizer contains quaternary ammonium groups. The range of number average molecular weight is about 250-5000, among which the number average molecular weight of about 250-1300 accounts for 85%.

Embodiment 3

[0033] Add 1.5 mol of dimethylamine into the three-necked flask, add 15 mol of distilled water under stirring conditions, slowly add 0.7 mol of epichlorohydrin dropwise using a constant pressure dropping funnel, control the acceleration to keep the temperature below 20°C, and keep warm for 1 hour after the dropping is completed; then Then add 0.8mol epichlorohydrin, and gradually raise the temperature to 80-85°C for 2 hours; then add 0.4mol triethylenetetramine, add 0.2mol epichlorohydrin dropwise, raise the temperature to 65-70°C for 2 hours, and dry the product under vacuum Then get clay stabilizer.

[0034] After testing, the stabilizer contains quaternary ammonium groups. The range of the number average molecular weight is about 250-5000, among which the number average molecular weight is about 250-1300 accounting for 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com