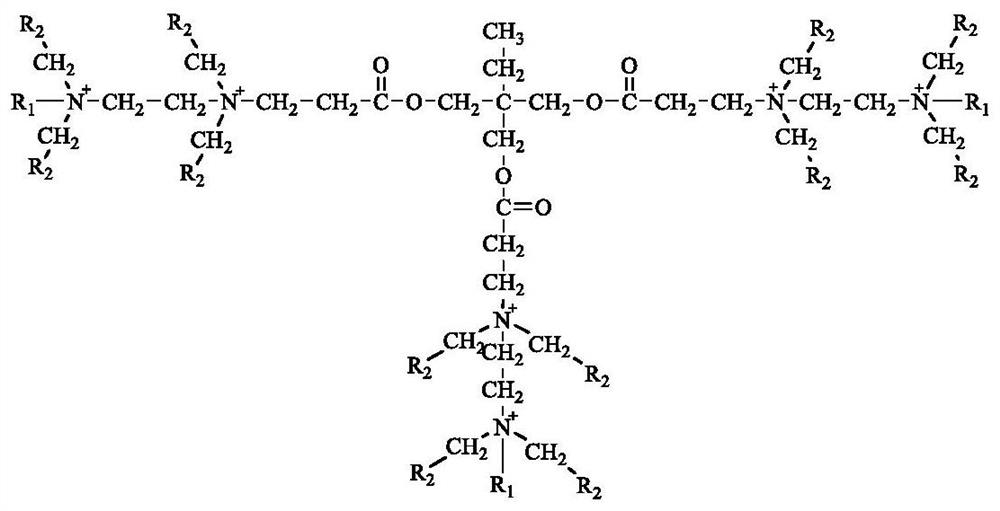

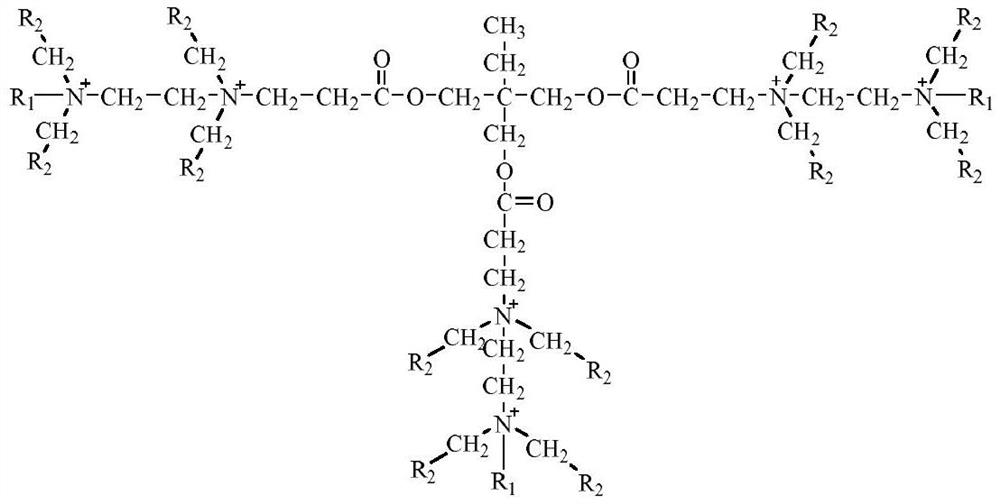

A kind of star polycation-based surfactant and its preparation method and application

A technology based on surfactants and polycations, which is applied in the field of star-shaped polycations-based surfactants and its preparation, can solve the problems of large formation damage, low anti-swelling rate, and large dosage, and achieve high-efficiency clay stabilizers and effects wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

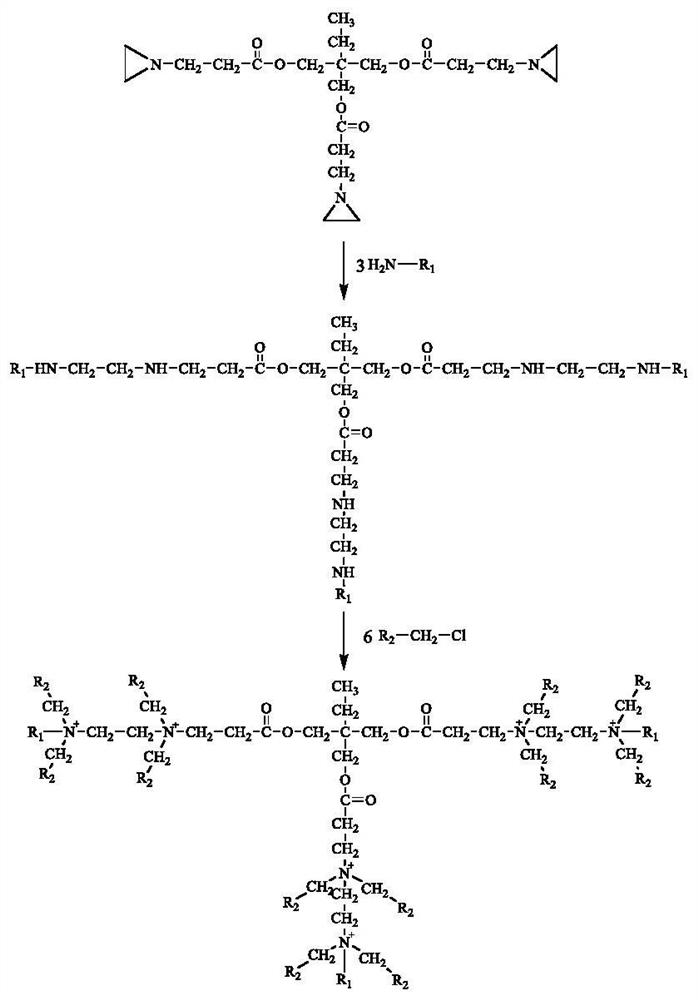

Method used

Image

Examples

Embodiment 1

[0035] (1) Be that 80% dodecyl primary amine ethanol solution (34.69g, wherein contain dodecyl primary amine 27.75g, 0.15mol) and acidic catalyst (85%H 3 PO 4 , 0.50g), be warming up to 50 ℃, dropwise add the trimethylolpropane-three (3- aziridinyl propionate) ethanol solution (35.42g, containing trimethylolpropane- Tris(3-aziridinyl propionate) 21.25 g, 0.05 mol), and the dropping time is 40 min. After the dropwise addition was completed, the temperature was raised to 70° C. for 6 h.

[0036] (2) The above reaction solution was mixed with K 2 CO 3 Adjust to weakly alkaline (pH=9~10), under the protection of nitrogen, add dropwise a 60% mass fraction of methyl chloride ethanol solution (25.25g, which contains 15.15g of methyl chloride, 0.30mol), and react at 50°C for 10h ; After the reaction, the insoluble matter was removed, the reaction solution was concentrated, the product was purified by toluene column chromatography, and the product was vacuum-dried to constant weigh...

Embodiment 2

[0042] (1) Be that 80% octadecyl primary amine ethanol solution (50.53g, wherein contain octadecyl primary amine 40.43g, 0.15mol) and acidic catalyst (85%H 3 PO 4 , 0.60g), be warming up to 50 ℃, dropwise add trimethylolpropane-three (3- aziridinyl propionate) ethanol solution (35.42g, containing trimethylolpropane- Tris(3-aziridinyl propionate) 21.25 g, 0.05 mol), and the dropping time is 40 min. After the dropwise addition was completed, the temperature was raised to 50° C. for 8 h.

[0043] (2) The above reaction solution was mixed with K 2 CO 3 Adjust to weakly alkaline (pH = 9 ~ 10), under the protection of nitrogen, dropwise add benzyl chloride ethanol solution (47.48g, containing 37.98g, 0.30mol) of benzyl chloride with a mass fraction of 80%, at 70°C React for 16 hours; remove the insoluble matter after the reaction, concentrate the reaction solution, purify and isolate the product by toluene column chromatography, and vacuum dry to constant weight to obtain the prod...

Embodiment 3

[0049] (3) Be that 80% tetradecyl primary amine ethanol solution (40.03g, wherein contain tetradecyl primary amine 32.03g, 0.15mol) and acid catalyst (85%H 3 PO 4 , 0.50g), be warming up to 50 ℃, dropwise add the trimethylolpropane-three (3- aziridinyl propionate) ethanol solution (35.42g, containing trimethylolpropane- Tris(3-aziridinyl propionate) 21.25 g, 0.05 mol), and the dropping time is 40 min. After the dropwise addition was completed, the temperature was raised to 60° C. for 7 h.

[0050] (4) The above-mentioned reaction liquid was mixed with K 2 CO 3 Adjust to weakly alkaline (pH = 9 ~ 10), under the protection of nitrogen, dropwise add benzyl chloride ethanol solution (47.48g, containing 37.98g, 0.30mol) of benzyl chloride with a mass fraction of 80%, at 60°C React for 12 hours; remove the insoluble matter after the reaction, concentrate the reaction solution, purify and isolate the product by toluene column chromatography, and dry it in vacuum to constant weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com