Production technology of novel copper-nickel-titanium orthodontic arch wire

A preparation process and dental arch wire technology, which is applied in the field of production and preparation of new copper-nickel-titanium dental arch wires, can solve the problem of low recovery rate of nickel-titanium alloy dental arch wires, increased doctor's chair-side working time, and initial loading Large force value and other problems, to achieve the effect of wide action range, lower loading force value, and lower frequency of wire replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

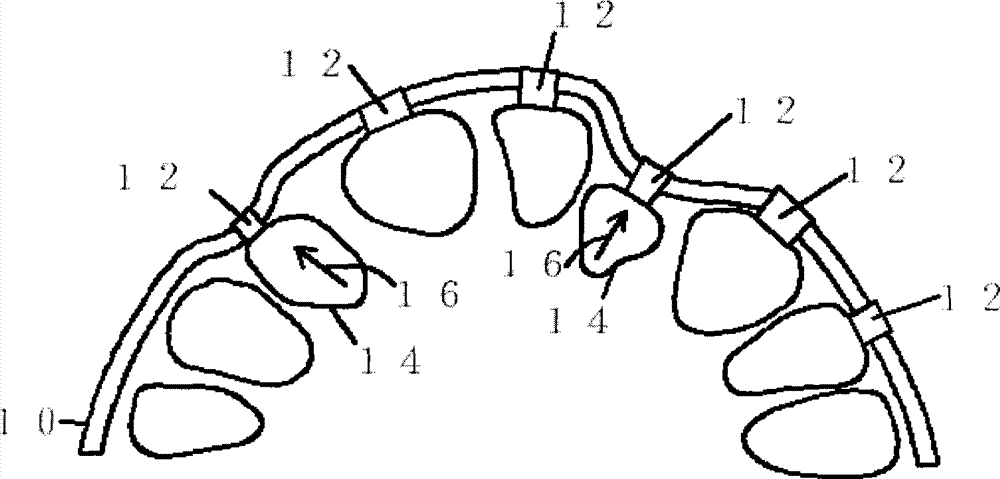

[0015] 1. Preparation of materials, the composition is Ni49.7%, Cu5.5%, Cr0.2%, and the balance is titanium.

[0016] 2. Wire drawing, the original wire diameter of the material is 1.2mm, and it is drawn to 0.41mm. The specific process is hot drawing-straightening-peeling-polishing-annealing-hot drawing-cold drawing-straightening-peeling-polishing, of which hot drawing The temperature is 720°C, straightened after four heat-drawings, the straightening temperature is 420°C, and the acid ratio for peeling is HF:HNO 3 :H 2 O=1:10:20, the annealing temperature is 750°C, and after two hot drawing and one cold drawing, the cold drawing deformation is 44.7%.

[0017] 3. Aging treatment. Adjust the temperature controller of the box-type resistance furnace to 530°C. After the temperature is stable, put the prefabricated dental arch wire into the furnace, adjust the holding time for 28 minutes, and take out the dental arch wire wrapped around it after the alarm sounds. The silk mold is...

Embodiment 2

[0020] The difference between this embodiment and the first embodiment is that the selected material composition is Ni48.2%, Cu6.5%, Cr0.7%, and the balance is titanium. The remaining steps and parameters are the same as in Embodiment 1.

Embodiment 3

[0022] The difference between this embodiment and Example 1 is that the heating method is different, and what selects in step 3 is a nitrate salt bath heating furnace. The remaining steps and parameters are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com