Water drainage and dynamic compaction all-in-one device and use method thereof

An integrated, rammer technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as hindering ramming, small force area of rammer, and inconspicuous effect, so as to accelerate the dissipation of pressure and improve the structure of the device Simple, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention will be further described.

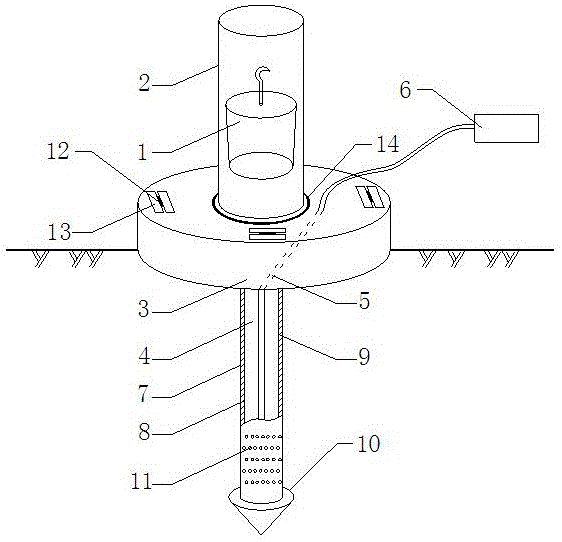

[0029] Such as figure 1 As shown, an integrated device for dewatering and dynamic ramming includes a rammer 1, a muffler sleeve 2, a ramming cap 3, a metal filter tube 4, a drainage hose 5 and a pump 6, and the ramming cap 3 is flat and solid Rigid cylinder, its diameter is 2-3 times of the diameter of tamper 1, and its thickness is 15~25cm;

[0030] The top of the ramming platform 3 is provided with a track groove 14, the track groove 14 and the ramming platform 3 are concentric circles, and the inner rotation of the track groove 14 is embedded with a sound-absorbing sleeve 2. The muffler sleeve 2 is a hollow steel cylinder whose height is freely adjusted by the lifting height of the rammer 1, and whose diameter is 1.2-1.5 times the diameter of the rammer 1, and the rammer 1 is arranged inside the muffler sleeve 2;

[0031] Around the periphery of the track groove 14 and on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com