Lining material for garbage burying field

A landfill and layered material technology, applied in the field of modified bentonite materials, can solve the problems of ineffective adsorption, inability to prevent the migration of organic pollutants, and extravasation of organic pollutants, and achieve good economic benefits and social benefits. Benefit, increase adsorption capacity, improve the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] This example is the preparation of organic bentonite.

[0024] The natural bentonite used in the experiment is natural calcium-based bentonite from Xuanhua, Hebei. The main mineral components are: bentonite 87.4%, quartz 3.6%, α-cristobalite 7.3%, potassium feldspar 0.7%, and other 1.0%. The cation exchange capacity is 83.87mlg / 100g soil, its chemical composition is shown in Table 1; Used modifying agent is chemically pure cetyltrimethylamine bromide (CTMAB).

[0025] Preparation:

[0026] Pass through a 100-mesh sieve after drying as it is and place it in a jar for later use. Weigh 40g of the original sample for each experiment, pour it into 200ml of a certain concentration of CTMAB solution, shake it well, put it into a constant temperature oscillator for 2.5h at a constant temperature, the temperature is 50°C, and the vibration speed is 170r·min -1 . Take it out, filter and wash it until there is no bromide ion, dry it at about 90°C, grind it and pass it through ...

example 2

[0032] This example is the preparation of metal bentonite.

[0033] through Na + , Ca 2+ 、Cu 2+ and Cr 3+ Saturated bentonite (raw material is with example 1) carries out X-ray analysis, and its bottom surface reflection d 001 The value of surface mesh spacing is shown in Table 3, that is, the order of the layer spacing of these kinds of bentonites from small to large is Na + 2+ 2+ al 3+ 3+ The larger interlayer distance of bentonite is conducive to the entry of organic molecules into the interlayer of bentonite.

[0034] Containing Na + , Ca 2+ 、Cu 2+ al 3+ and Cr 3+ The chemical analysis of bentonite, which contains CaO, Na 2 O, CuO, Al 2 o 3 、Cr 2 o 3 and the mass percentage of adsorbed water are shown in Table 4. It can be seen from Table 4 that more water molecules surround the high-valence cations, and these water molecules can form hydrogen bonds with hydroxyl organic molecules, thereby absorbing a larger amount of organic matter.

example 3

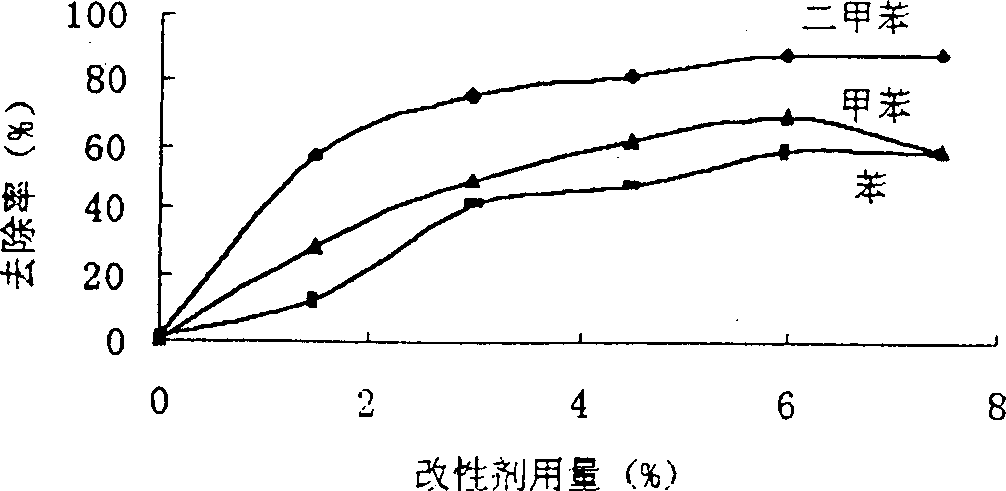

[0036] This example is the adsorption experiment of organic bentonite on phenol, aniline, benzene series and chloroform.

[0037] 1. Organobentonite adsorption of phenol experiment

[0038] Experimental conditions: The initial concentration of phenol is 10mg / 1, the amount of bentonite is 2.5g, and the adsorption experiment is carried out. The experimental process is to shake at a constant temperature for 10 minutes at a vibration speed of 150r / min at room temperature, centrifuge, pass through the membrane, and measure the remaining concentration. The same below. The results are shown in Table 5, which shows that with the increase of the amount of modifier, the adsorption capacity of organobentonite to phenol is enhanced.

[0039] 2. Organobentonite adsorption of aniline experiment

[0040] Experimental conditions: organic bentonite dosage 2.0g, solution volume 25ml, initial concentration of aniline 20mg / l, neutral pH value, removal rate of aniline up to 90%, and equilibrium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com