Gas-solid zero-leakage discharging sealing device

A sealing device, gas-solid technology, applied in the direction of the valve device, engine sealing, valve lift, etc., can solve the problems of short service life of the ash unloading valve, serious, solid material wear and tear on the sealing surface, etc., achieve significant energy saving and consumption reduction, and can be implemented Strong, reduce the effect of air leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

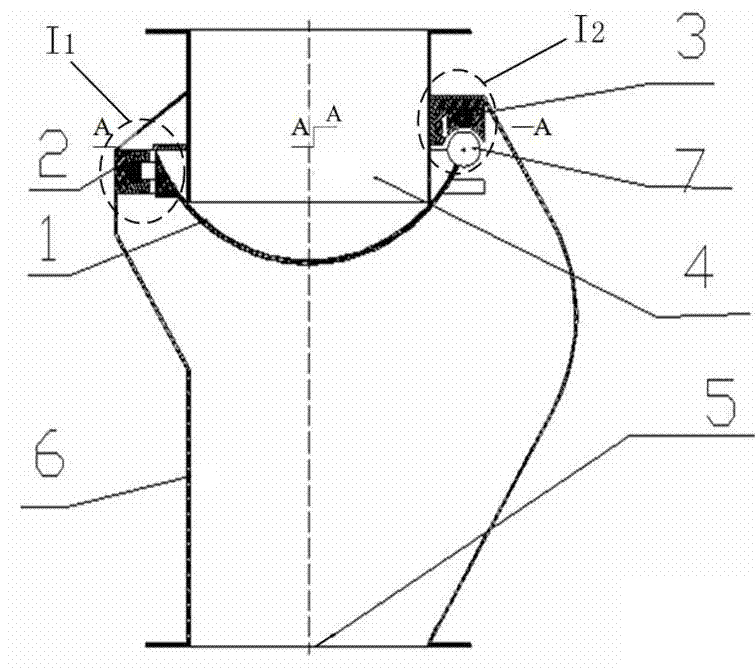

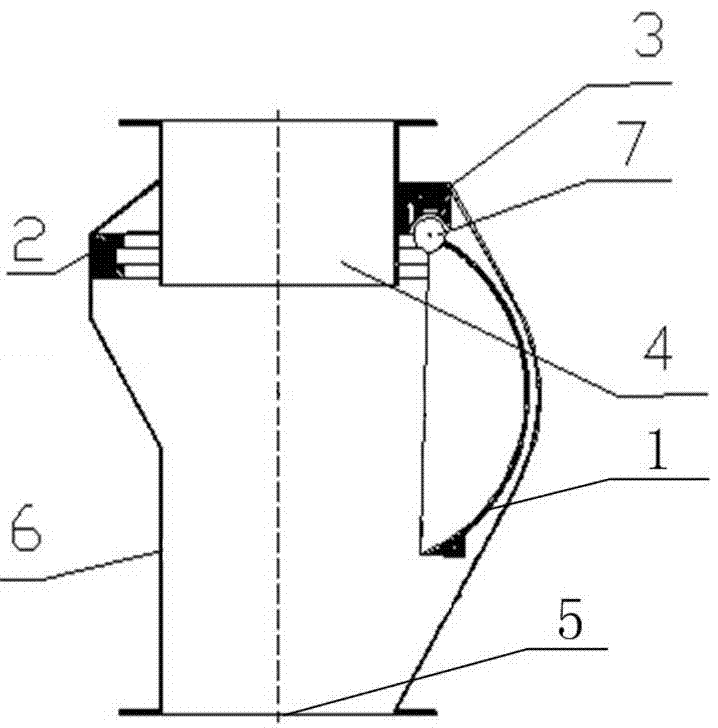

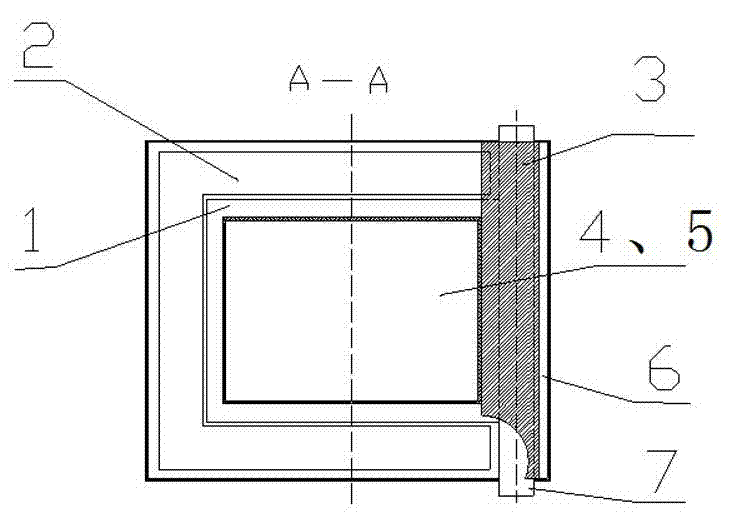

[0018] Such as Figure 1-Figure 3 The gas-solid non-leakage discharge sealing device shown is characterized in that it includes a hinge shaft 7 arranged outside the discharge port 4, and a valve plate that is integrated with the hinge shaft 7 and opens and closes toward the discharge port 4. 1. The "one"-shaped magnetic seal 3 arranged on the outer surface of the discharge port 4 on the same side as the hinge shaft 7 and the "U"-shaped magnetic seal 2 arranged on the other three outer surfaces of the discharge port 4; A magnetizer 1-1 is provided on the surface of the valve plate 1 in contact with the "U"-shaped magnetic seal 2. Both the hinge shaft 7 and the magnetizer 1-1 are made of ferromagnetic materials with high magnetic permeability.

[0019] The valve plate 1 is an arc-shaped bottom valve plate with a pair of side walls on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com