A kind of clay stabilizer and its application

A clay stabilizer and reaction technology, which is applied in the field of clay stabilizer preparation, can solve the problems of high molecular weight, low anti-swelling rate, and formation damage of polymer clay stabilizers, and achieve the purpose of inhibiting hydration expansion and dispersion migration, preventing The effect of high expansion rate and high degree of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 1.2 mol of trimethylamine into a three-necked flask, add 10 mol of distilled water under stirring conditions, slowly add 0.5 mol of epichlorohydrin dropwise through a constant pressure dropping funnel, control acceleration to keep the temperature below 20°C, and keep warm for 1 hour after dropping; Add 0.5mol epichlorohydrin, gradually raise the temperature to 90-95°C and react for 2 hours; then add 0.4mol triethylenetetramine, add 0.5mol epichlorohydrin dropwise, raise the temperature to 65-70°C and react for 2 hours, and the product is vacuum-dried Get clay stabilizers.

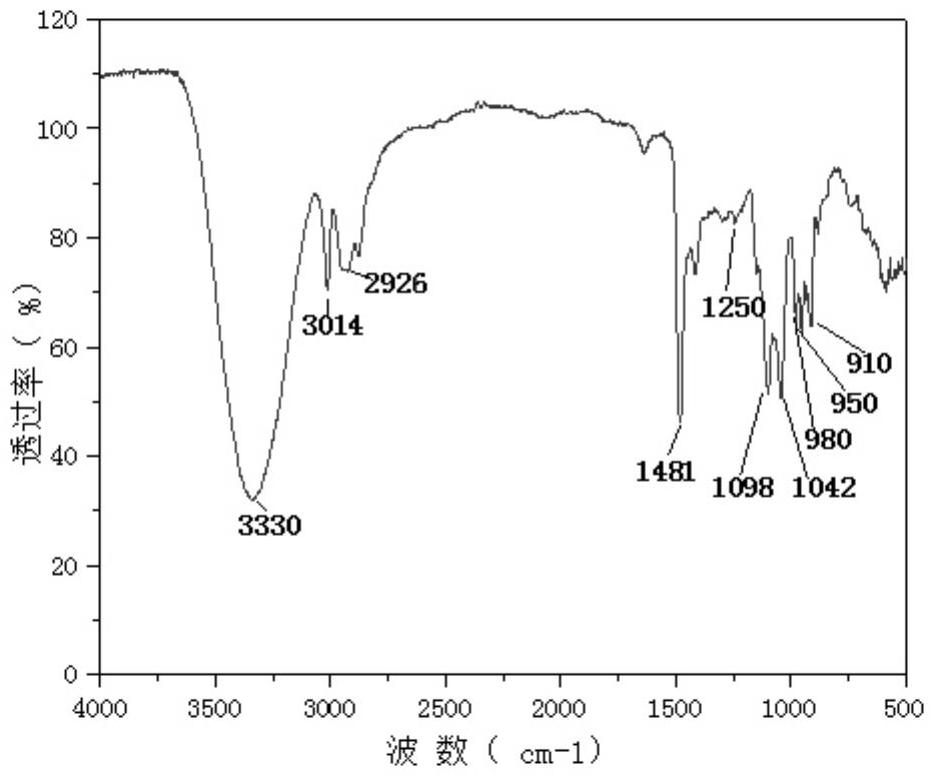

[0027] Infrared characterization of the clay stabilizer was carried out by figure 1 It can be seen that 1250cm -1 、980cm -1 It is the characteristic absorption peak of C-N, 2900~3000cm -1 It is the C-H stretching vibration peak in methyl and methylene, and there is no N-H absorption peak in this figure, 3330cm -1 The hydroxyl peak at place is the characteristic peak of water after the potassi...

Embodiment 2

[0030] Add 1.2 mol of dimethylamine into the three-necked flask, add 10 mol of distilled water under stirring conditions, slowly add 0.4 mol of epichlorohydrin dropwise using a constant pressure dropping funnel, control the acceleration to keep the temperature below 20°C, and keep warm for 1 hour after the dropping is completed; then Then add 0.4mol epichlorohydrin, and gradually raise the temperature to 80-85°C for 2 hours; then add 0.4mol triethylenetetramine, add 0.4mol epichlorohydrin dropwise, raise the temperature to 65-70°C for 2 hours, and dry the product under vacuum Then get clay stabilizer.

[0031] After testing, the stabilizer contains quaternary ammonium groups. The range of number average molecular weight is about 250-5000, among which the number average molecular weight of about 250-1300 accounts for 85%.

Embodiment 3

[0033] Add 1.5 mol of dimethylamine into the three-necked flask, add 15 mol of distilled water under stirring conditions, slowly add 0.7 mol of epichlorohydrin dropwise using a constant pressure dropping funnel, control the acceleration to keep the temperature below 20°C, and keep warm for 1 hour after the dropping is completed; then Then add 0.8mol epichlorohydrin, and gradually raise the temperature to 80-85°C for 2 hours; then add 0.4mol triethylenetetramine, add 0.2mol epichlorohydrin dropwise, raise the temperature to 65-70°C for 2 hours, and dry the product under vacuum Then get clay stabilizer.

[0034] After testing, the stabilizer contains quaternary ammonium groups. The range of the number average molecular weight is about 250-5000, among which the number average molecular weight is about 250-1300 accounting for 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com