A papermaking wastewater treatment system and method

A technology of papermaking wastewater and treatment system, which is applied in the direction of processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Difficult to control conditions, unsatisfactory wastewater treatment effect, etc., to achieve ideal purification effect, improved degree, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further clarified below in conjunction with the drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

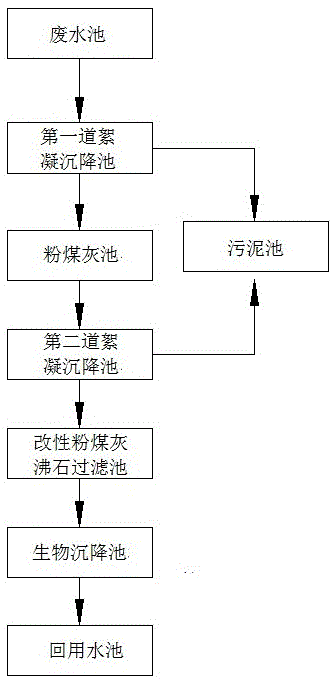

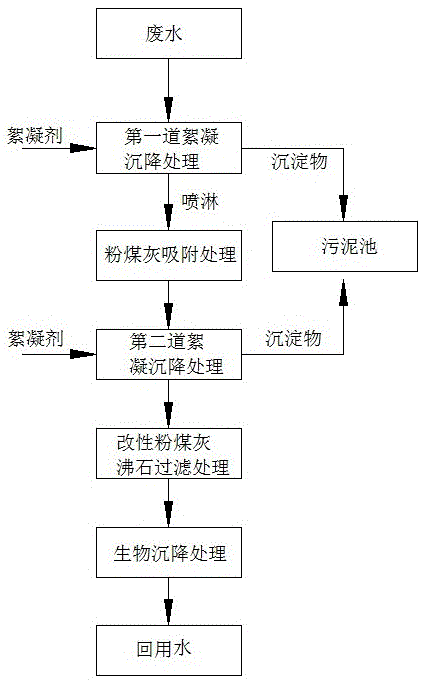

[0036] As can be seen from the attached drawings, a papermaking wastewater treatment system, including wastewater tank, first flocculation sedimentation tank, fly ash tank, second flocculation sedimentation tank, modified fly ash zeolite filter, biological sedimentation tank and reuse The wastewater pool is used to receive wastewater from the wastewater discharge pipeline of the papermaking workshop; the first flocculation sedimentation tank is equipped with a stirring device, and the bottom of the first flocculation sedimentation tank is provided with a sludge tank. The inlet end of the first flocculation sedimentation tank is connected to the waste water tank, and the outlet end of the first fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com