Method for preparing heat-insulation bricks with high compressive strength

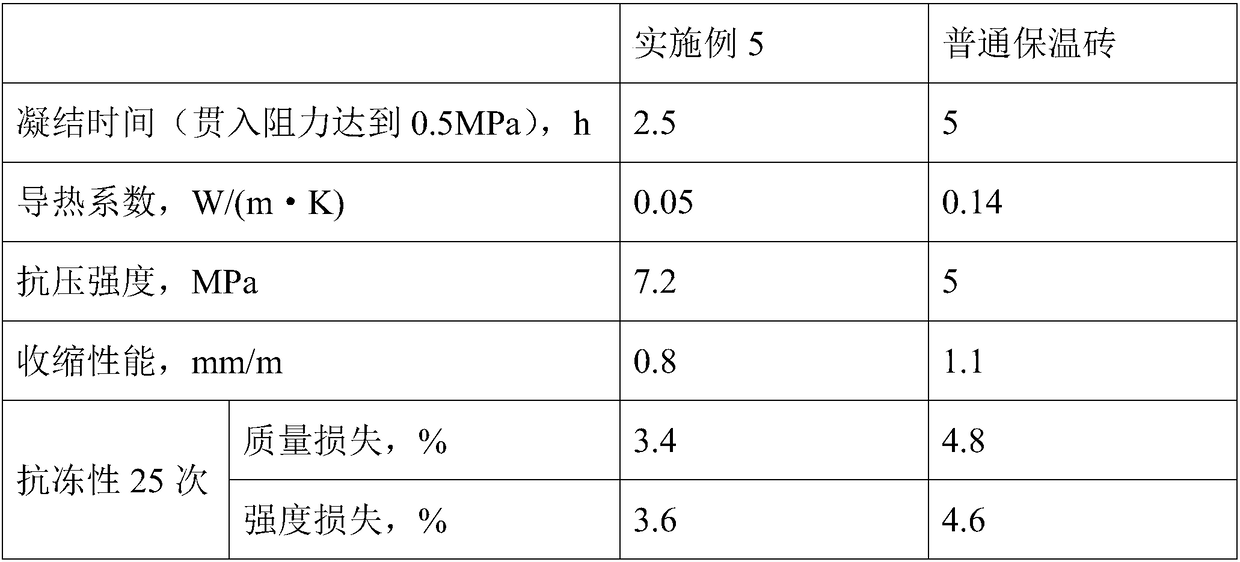

A technology of compressive strength and thermal insulation bricks, applied in the field of thermal insulation bricks, can solve the problems of easy powdery, fragile, insufficient strength, etc., and achieve the effect of high adsorption degree, short final setting time and rapid strength development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for preparing a heat insulating brick with high compressive strength, comprising the steps of:

[0017] S1. Add 25kg corncob powder into 160kg potassium hydroxide solution with a concentration of 1.4mol / L, heat up to 76°C and stir for 80min, filter, vacuum dry at 125°C for 4h, carbonize at 800°C for 8min, grind, add 12kg humic acid, 80kg water, ultrasonically dispersed for 40 minutes, filtered, vacuum-dried at 135°C for 6 hours, and crushed to obtain a prefabricated material;

[0018] S2, 60kg of construction waste, 30kg of prefabricated material, 15kg of mica powder, 16kg of blast furnace slag, 6kg of hydroxyethyl cellulose, 12kg of diatomaceous earth, 8kg of acrylonitrile-based carbon fiber, 10kg of sepiolite powder, 8kg of gravel, 0.8kg of triethanolamine, 2kg of sodium bicarbonate, 8kg of ethylene-vinyl acetate copolymer, 25kg of cement, 4kg of heavy calcium carbonate, and 1.5kg of calcium chloride were mixed, pulverized, then added with 120kg of water and ...

Embodiment 2

[0020] A method for preparing a heat insulating brick with high compressive strength, comprising the steps of:

[0021] S1. Add 35kg corncob powder into 80kg potassium hydroxide solution with a concentration of 2mol / L, heat up to 70°C and stir for 120min, filter, vacuum dry at 115°C for 8h, carbonize at 780°C for 16min, grind, add 6kg humic acid and 120kg water , ultrasonically dispersed for 20 minutes, filtered, vacuum-dried at 145°C for 3 hours, and pulverized to obtain a prefabricated material;

[0022] S2, 80kg of construction waste, 20kg of prefabricated material, 25kg of mica powder, 4kg of blast furnace slag, 10kg of hydroxyethyl cellulose, 6kg of diatomaceous earth, 16kg of acrylonitrile-based carbon fiber, 4kg of sepiolite powder, 16kg of gravel, 0.4kg of triethanolamine, 4kg of sodium bicarbonate, 4kg of ethylene-vinyl acetate copolymer, 35kg of cement, 2kg of heavy calcium carbonate, and 2.5kg of calcium chloride were mixed, pulverized, then added with 80kg of water...

Embodiment 3

[0024] A method for preparing a heat insulating brick with high compressive strength, comprising the steps of:

[0025] S1. Add 28kg corncob powder into 140kg potassium hydroxide solution with a concentration of 1.6mol / L, heat up to 74°C and stir for 90min, filter, vacuum dry at 122°C for 5h, carbonize at 795°C for 10min, grind, add 10kg humic acid, 90kg water, ultrasonically dispersed for 35 minutes, filtered, vacuum-dried at 138°C for 5 hours, and pulverized to obtain a prefabricated material;

[0026] S2, 65kg of construction waste, 28kg of prefabricated material, 18kg of mica powder, 14kg of blast furnace slag, 7kg of hydroxyethyl cellulose, 10kg of diatomaceous earth, 10kg of acrylonitrile-based carbon fiber, 8kg of sepiolite powder, 10kg of gravel, 0.7kg of triethanolamine, 2.5kg of sodium bicarbonate, 7kg of ethylene-vinyl acetate copolymer, 28kg of cement, 3.5kg of heavy calcium carbonate, and 1.8kg of calcium chloride were mixed and crushed, then 110kg of water was ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com