A bio-oxidation harmless treatment process for arsenic-containing hazardous waste

A harmless treatment and biological oxidation technology, applied in the field of environmental pollution control, can solve the problems of large area occupied by the aeration tank, large power consumption for stirring, low arsenic removal rate, etc., and achieve the effect of easily intercepting wind power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1. This embodiment provides a process for the harmless treatment of arsenic-containing hazardous waste by biological oxidation, which includes the following steps:

[0062] S1. Oxidize the arsenic-containing waste, so that the trivalent arsenic in the waste is oxidized to pentavalent arsenic, which reduces the toxicity to microorganisms in the activated sludge; trivalent arsenic is highly toxic and has a significant toxic effect on microorganisms, so first carry out Oxidation, and there are many ways to oxidize trivalent arsenic to pentavalent arsenic, but I will not describe more.

[0063] S2. Put the oxidized arsenic-containing waste into the three-dimensional aeration tank, and add activated sludge in the three-dimensional aeration tank; the concentration of heavy metal ions in the added pentavalent arsenic waste should be less than 30 mg•L-1, so that the activated sludge has no effect on arsenic The removal rate of ions is higher.

[0064] S3. The three-...

Embodiment 2

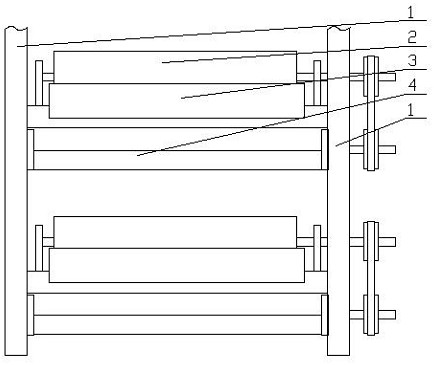

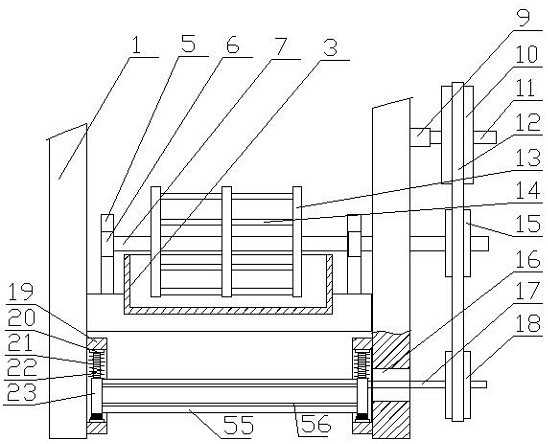

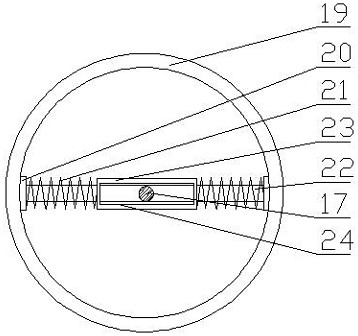

[0068] Embodiment two, such as Figure 1 to Figure 14 As shown, it discloses that the three-dimensional aeration tank includes two matched reinforced concrete first columns 1, and several layers of aeration tanks 3 with a rectangular horizontal cross-section are arranged on the first column 1, and the aeration tanks 3 The vertical section is semicircular, and the space for installing the wind-driven rotating mechanism 4 is reserved between the upper and lower layers of the aeration tank 3. The aeration tank 3 is provided with a stirring device 2, and the wind-driven rotating mechanism 4 It is connected with the agitation device 2 in the aeration tank 3 on the upper floor. The side of the first column 1 is provided with a first drive motor 38 corresponding to the agitation device 2. A controller is provided in the control room corresponding to the first drive motor 38. . The aeration tank is set up in multiple layers, first of all, it occupies a small area, and secondly, it ca...

Embodiment 3

[0078] Embodiment 3. This embodiment provides an aeration method for a three-dimensional aeration tank, which includes the following steps:

[0079]A. Monitor the on-site wind force. When the wind force is greater than or equal to level 4, the tensioning mechanism tensions the belt, the first drive motor drives the rotating shaft to rotate, and the rotating rod is driven to rotate through the belt drive, so that the rotating rod is in a vertical state and slides The sleeve drives the windshield to move down under the action of gravity, and then the first drive motor exits, and the wind pushes the lower windshield to drive the rotating rod to rotate. When the rotating rod is horizontal, the sliding sleeve is located in the middle of the rotating rod under the action of the spring and rotates The rod continues to rotate, and at this time, the sliding sleeve will fall to the lower part of the rotating rod due to gravity, and continue to push the rotating rod to rotate in one direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com