Anti-slippage composite base material boiler body outer surface polishing and grinding machine

A composite base material, polishing and grinding technology, which is applied in the direction of surface polishing machine tools, grinding racks, grinding/polishing equipment, etc., can solve the problems of rough and uneven surface of the pot embryo, damage of the pot body by the polishing machine, and affecting the polishing efficiency, etc. , to achieve the effect of improved adsorption, stable movement and comprehensive polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

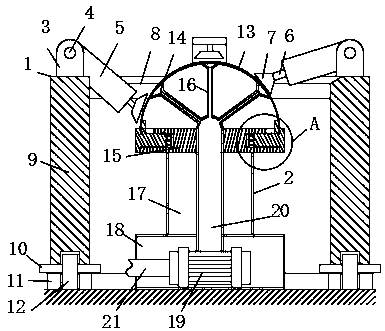

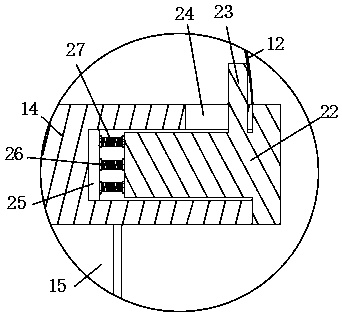

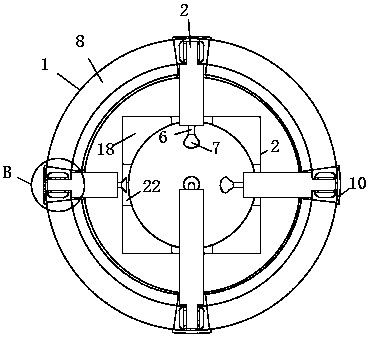

[0029] An anti-slip composite base material pan body outer surface polishing machine, including a polishing mechanism 1 and a clamping mechanism 2, the outer side of the polishing mechanism 1 is a support column 9, and the upper end of the support column 9 is integrally formed with a polishing frame fixing seat 3 , the polishing frame fixing seat 3 is bolted to the end of the polishing frame 5 by fastening bolts 4, the front end of the polishing frame 5 is fixedly connected to the polishing wheel shaft 6, the front end of the polishing wheel shaft 6 is fixedly connected to the polishing wheel 7, and the lower end of the support column 9 is provided with a stabilizing plate 10. The pulley 12 is fixedly connected to the stabilizing plate 10, and the pulley 12 is slidably connected in the chute 11. The chute 11 is circular and fixed outside the clamping mechanism 2. The upper end of the clamping mechanism 2 is provided with a placement plate 15. Each of the four sides of the board...

Embodiment 2

[0031]An anti-slip composite base material pan body outer surface polishing machine, including a polishing mechanism 1 and a clamping mechanism 2, the outer side of the polishing mechanism 1 is a support column 9, and the upper end of the support column 9 is integrally formed with a polishing frame fixing seat 3 , the polishing frame fixing seat 3 is bolted to the end of the polishing frame 5 by fastening bolts 4, the front end of the polishing frame 5 is fixedly connected to the polishing wheel shaft 6, the front end of the polishing wheel shaft 6 is fixedly connected to the polishing wheel 7, and the lower end of the support column 9 is provided with a stabilizing plate 10. The pulley 12 is fixedly connected to the stabilizing plate 10, and the pulley 12 is slidably connected in the chute 11. The chute 11 is circular and fixed outside the clamping mechanism 2. The upper end of the clamping mechanism 2 is provided with a placement plate 15. Each of the four sides of the board ...

Embodiment 3

[0034] An anti-slip composite base material pan body outer surface polishing machine, including a polishing mechanism 1 and a clamping mechanism 2, the outer side of the polishing mechanism 1 is a support column 9, and the upper end of the support column 9 is integrally formed with a polishing frame fixing seat 3 , the polishing frame fixing seat 3 is bolted to the end of the polishing frame 5 by fastening bolts 4, the front end of the polishing frame 5 is fixedly connected to the polishing wheel shaft 6, the front end of the polishing wheel shaft 6 is fixedly connected to the polishing wheel 7, and the lower end of the support column 9 is provided with a stabilizing plate 10. The pulley 12 is fixedly connected to the stabilizing plate 10, and the pulley 12 is slidably connected in the chute 11. The chute 11 is circular and fixed outside the clamping mechanism 2. The upper end of the clamping mechanism 2 is provided with a placement plate 15. Each of the four sides of the board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com