High-temperature high-pressure jig dyeing device for cotton cloth production and processing

A high-temperature, high-pressure, cotton-cloth technology, which is applied to textile processing machine accessories, textile material processing, and textile material processing equipment configuration, can solve the problems of dye accumulation and precipitation, poor dye adsorption, low temperature and pressure, etc., and achieve better jigger quality Excellent, promotes adsorption efficiency, and avoids the effect of dye accumulation and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

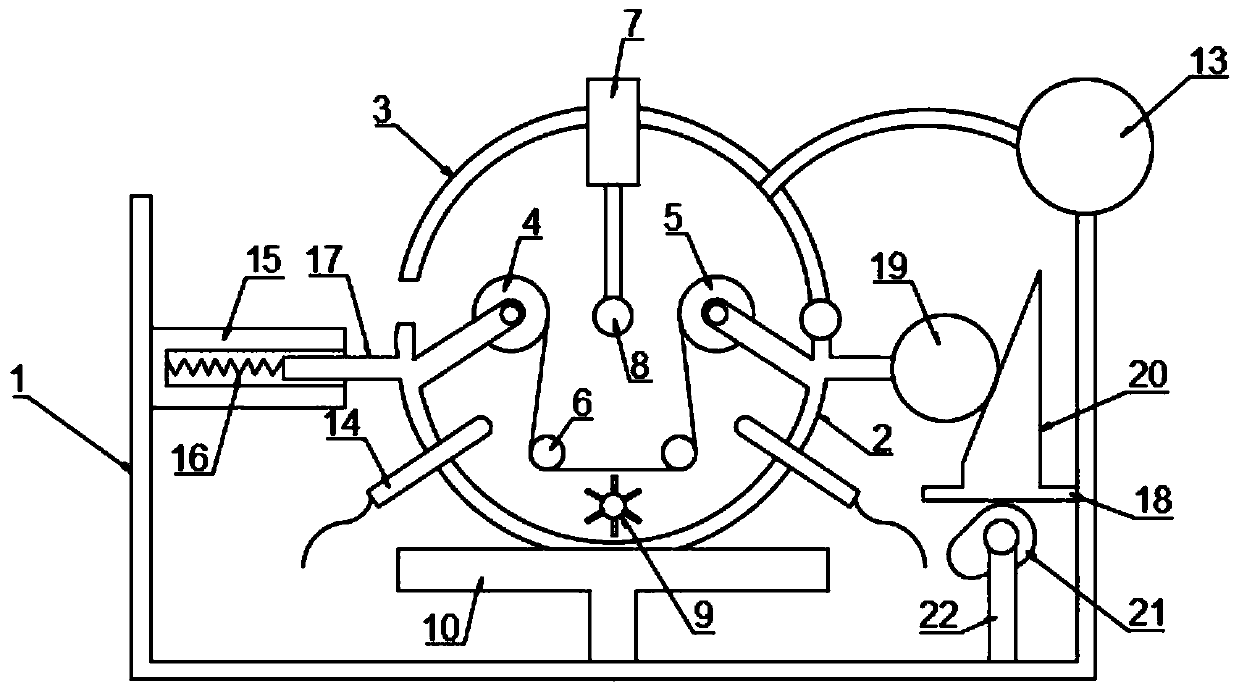

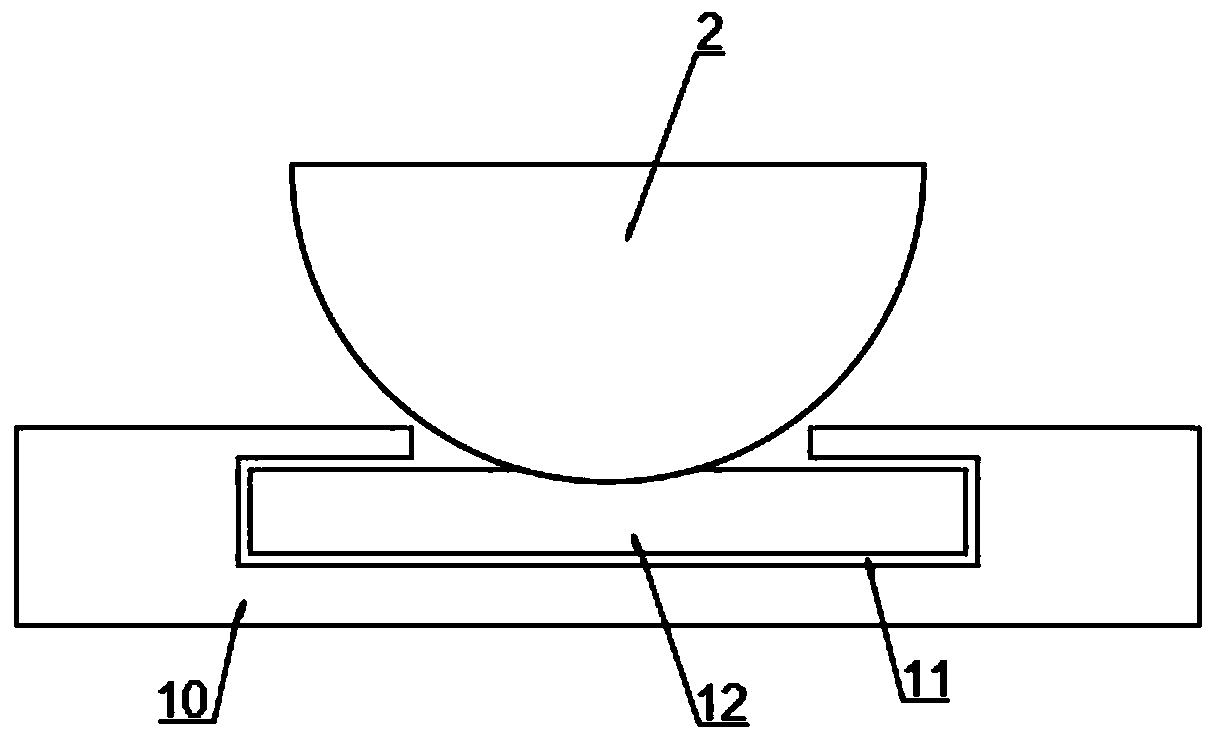

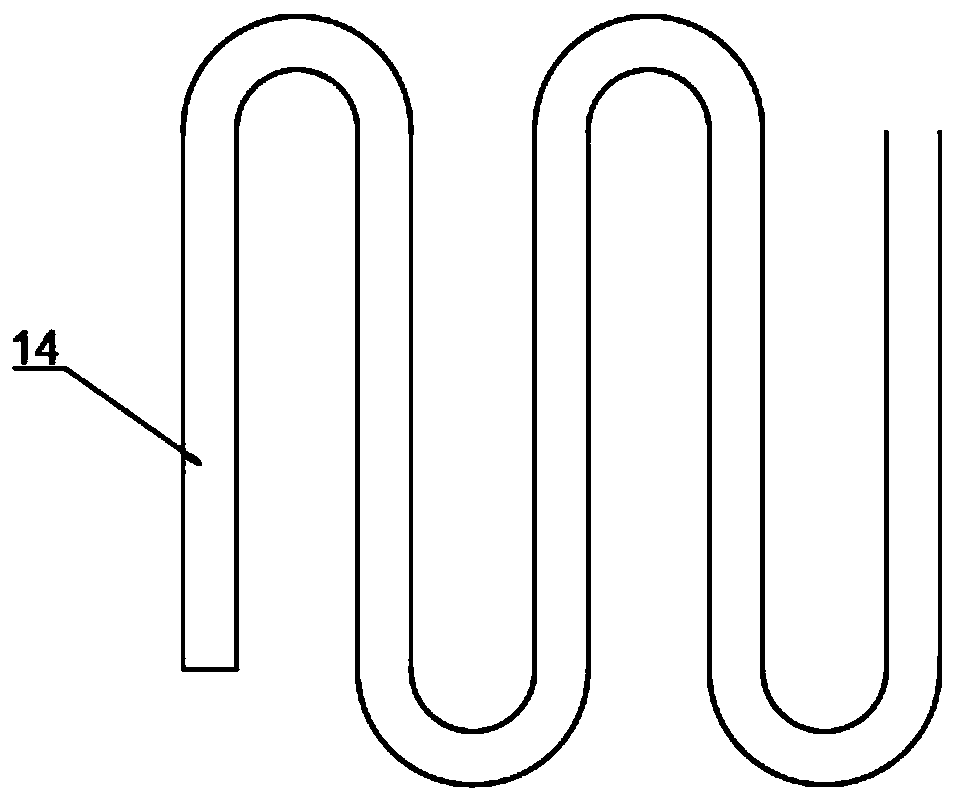

[0027] refer to Figure 1-3 A high-temperature and high-pressure dyeing device for cotton production and processing, comprising an installation slot 1 and a container located in the installation slot 1, the container is composed of a semicircular slot 2 located at the lower end and an upper cover 3 located at the upper end that matches the semicircular slot 2, and the upper The cover 3 is semicircular, and the specifications of the upper cover 3 and the semicircular groove 2 are consistent. It is further explained that the upper cover 3 is rotationally connected with the semicircular groove 2. When the upper cover 3 is rotated to fit the semicircular groove 2, the sealing of the container is realized. The semi-circular groove 2 is provided with dyestuffs, and the inner wall of the semi-circular groove 2 is equipped with a cloth winding roller 4 and a cloth releasing roller 5. The inside of the semicircular groove 2 is also fixed with two lower rollers located at the lower sides...

Embodiment 2

[0032] refer to Figure 2-4 , refer to Figure 1-3A high-temperature and high-pressure dyeing device for cotton production and processing, comprising an installation slot 1 and a container located in the installation slot 1, the container is composed of a semicircular slot 2 located at the lower end and an upper cover 3 located at the upper end that matches the semicircular slot 2, and the upper The cover 3 is semicircular, and the specifications of the upper cover 3 and the semicircular groove 2 are consistent. It is further explained that the upper cover 3 is rotationally connected with the semicircular groove 2. When the upper cover 3 is rotated to fit the semicircular groove 2, the sealing of the container is realized. The semi-circular groove 2 is provided with dyestuffs, and the inner wall of the semi-circular groove 2 is equipped with a cloth winding roller 4 and a cloth releasing roller 5. The inside of the semicircular groove 2 is also fixed with two lower rollers loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com