Continuous integrated sewage treatment device

A sewage treatment device and sewage treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as easy sediment accumulation, inconvenient maintenance, and limited scope of application. Achieve high efficiency of filtration and purification, avoid sedimentation and accumulation, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

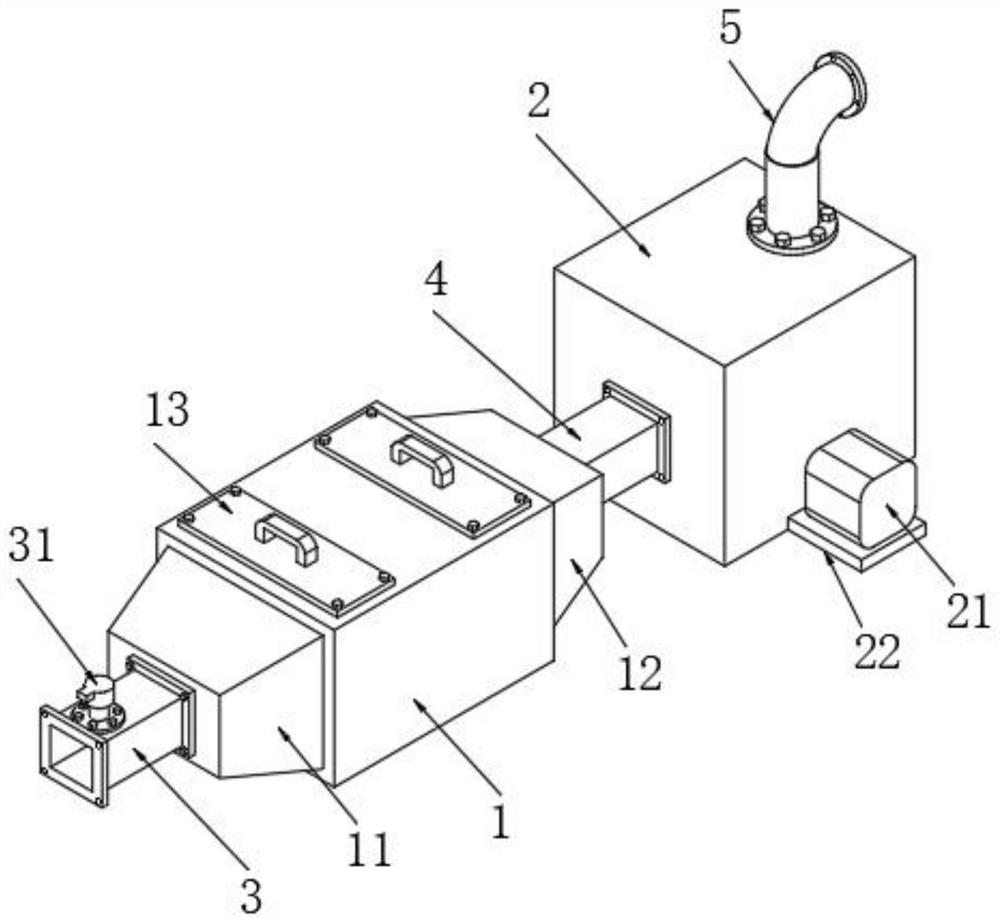

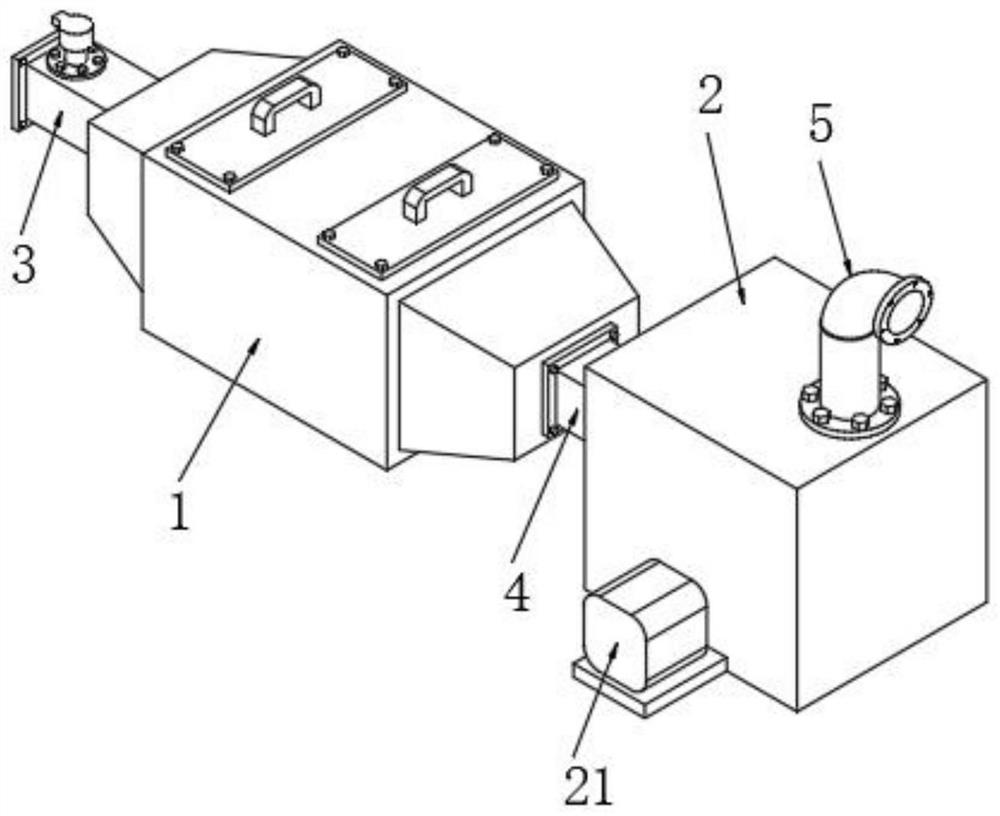

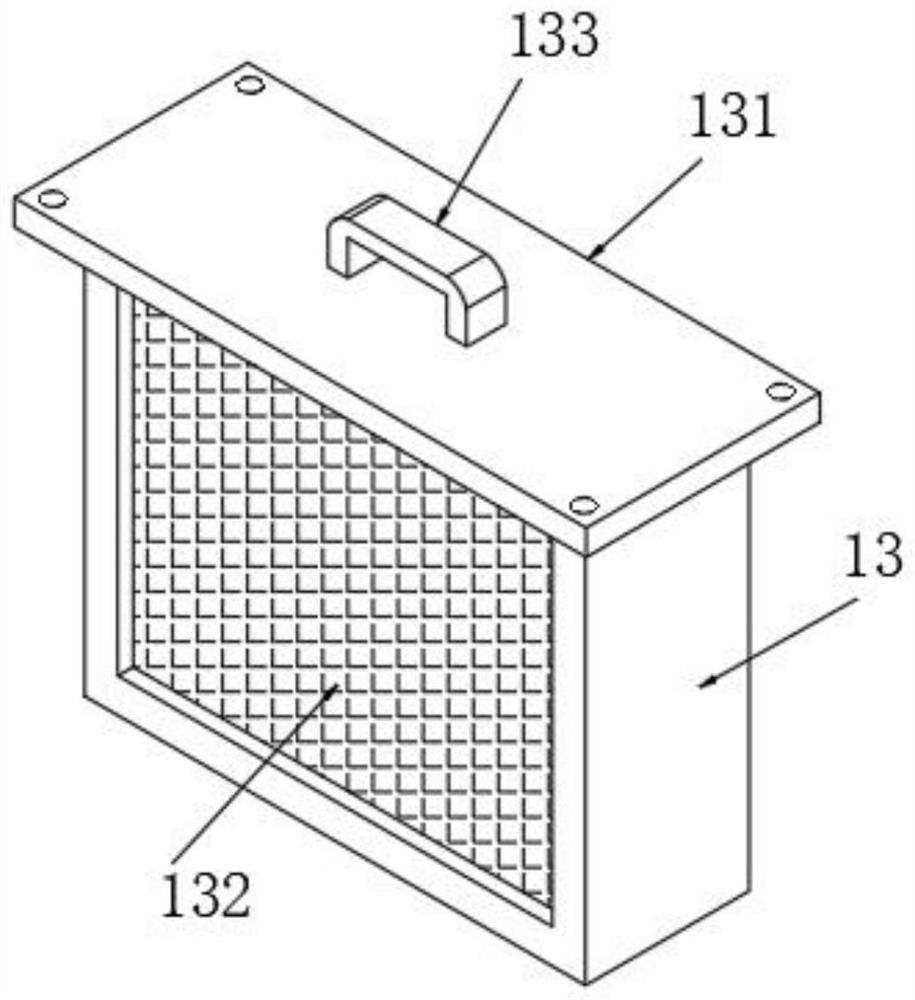

[0036]The embodiment of the present invention provides a technical solution: a continuous integrated sewage treatment device, including a first sewage treatment tank 1 and a second sewage treatment tank 2, the left end of the first sewage treatment tank 1 is fixed with a liquid inlet cavity 11, the right end of the first sewage treatment tank 1 is fixedly provided with a liquid outlet cavity 12, the interior of the first sewage treatment tank 1 is distributed with a purification device 13, and the liquid inlet pipe 3 is arranged at the end of the liquid inlet chamber 11 At the left end, the liquid transfer pipe 4 is fixed between the liquid outlet chamber 12 and the second sewage treatment tank 2, and the liquid outlet pipe 5 is connected to the top right end of the second sewage treatment tank 2 through a flange. The liquid pipe 5 is an elbow structure, and the filter element inside the liquid outlet pipe 5 can be further purified and discharged; both ends of the liquid inlet ...

example 2

[0038] The embodiment of the present invention provides a technical solution: a continuous integrated sewage treatment device, including a first sewage treatment tank 1 and a second sewage treatment tank 2, the left end of the first sewage treatment tank 1 is fixed with a liquid inlet cavity 11, the right end of the first sewage treatment tank 1 is fixedly provided with a liquid outlet cavity 12, the interior of the first sewage treatment tank 1 is distributed with a purification device 13, and the liquid inlet pipe 3 is arranged at the end of the liquid inlet chamber 11 At the left end, the liquid transfer pipe 4 is fixed between the liquid outlet chamber 12 and the second sewage treatment tank 2, and the liquid outlet pipe 5 is connected to the top right end of the second sewage treatment tank 2 through a flange. The liquid pipe 5 is an elbow structure, and the filter element inside the liquid outlet pipe 5 can be further purified and discharged; the front end of the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com