Sand mold spraying device

A spraying device and sand mold technology, applied in the field of mold manufacturing, can solve the problems of liquid paint precipitation, multi-working space, uneven spraying, etc., and achieve the effect of preventing the accumulation of paint deposits and uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

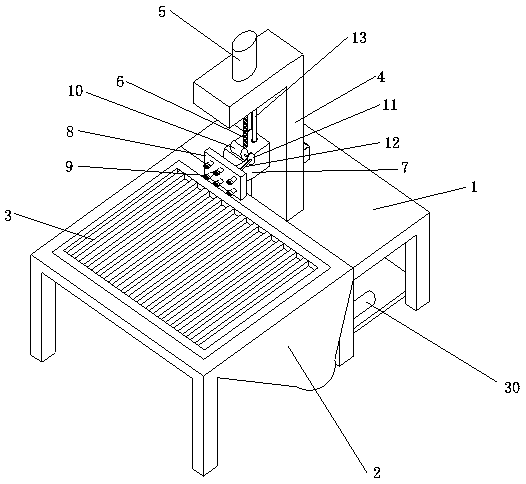

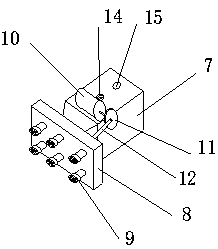

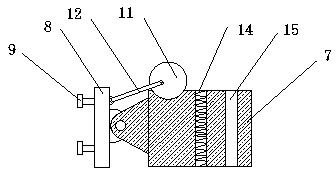

[0027] Embodiment: a kind of sand mold spraying device, as attached Figure 1-5 As shown, including the workbench 1, the side of the workbench 1 is provided with a paint recovery box 2 with a triangular cross-section, and the top of the paint recovery box 2 is provided with a network frame 3; the network frame 3 is arranged on the paint recovery box 2 side by side. The metal tube at the top plays a protective role. The workbench 1 is provided with a vertically upward inverted L-shaped support frame 4 on one side of the paint recovery box 2, and a lifting motor 5 is provided above the support frame 4, and a vertical shaft is connected to the output shaft of the lifting motor 5. The lower screw rod 6 is provided with a lifting slider 7 on the screw rod 6, and the lifting slider 7 is provided with a threaded hole 14 cooperating with the screw rod 6; the support frame 4 is provided with a vertically downward limiting column 13; The lift slider 7 is provided with a limit through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com