Inner cavity electroplating equipment of engine cylinder body

A technology for engine cylinder block and electroplating equipment, which is applied in the direction of plating tank, electrolysis process, electrolysis components, etc., to achieve the effect of prolonging service life, strong wear resistance, and preventing precipitation and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

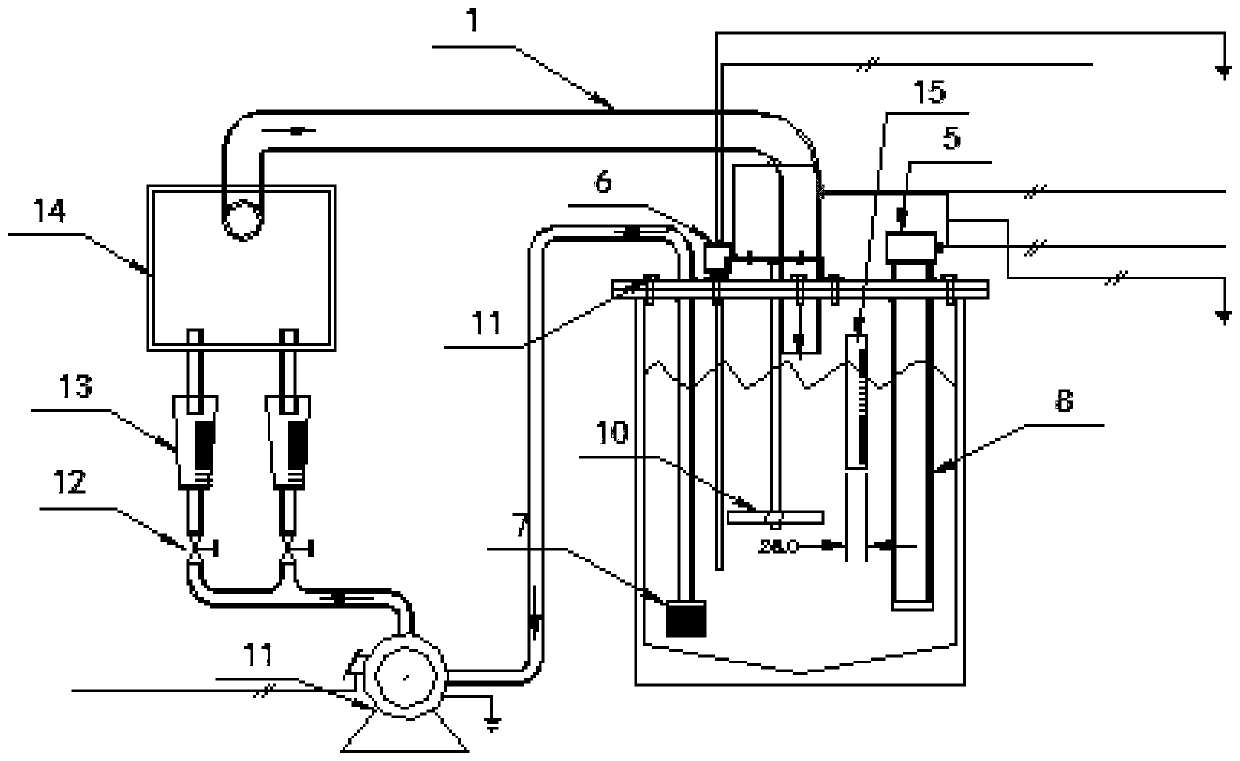

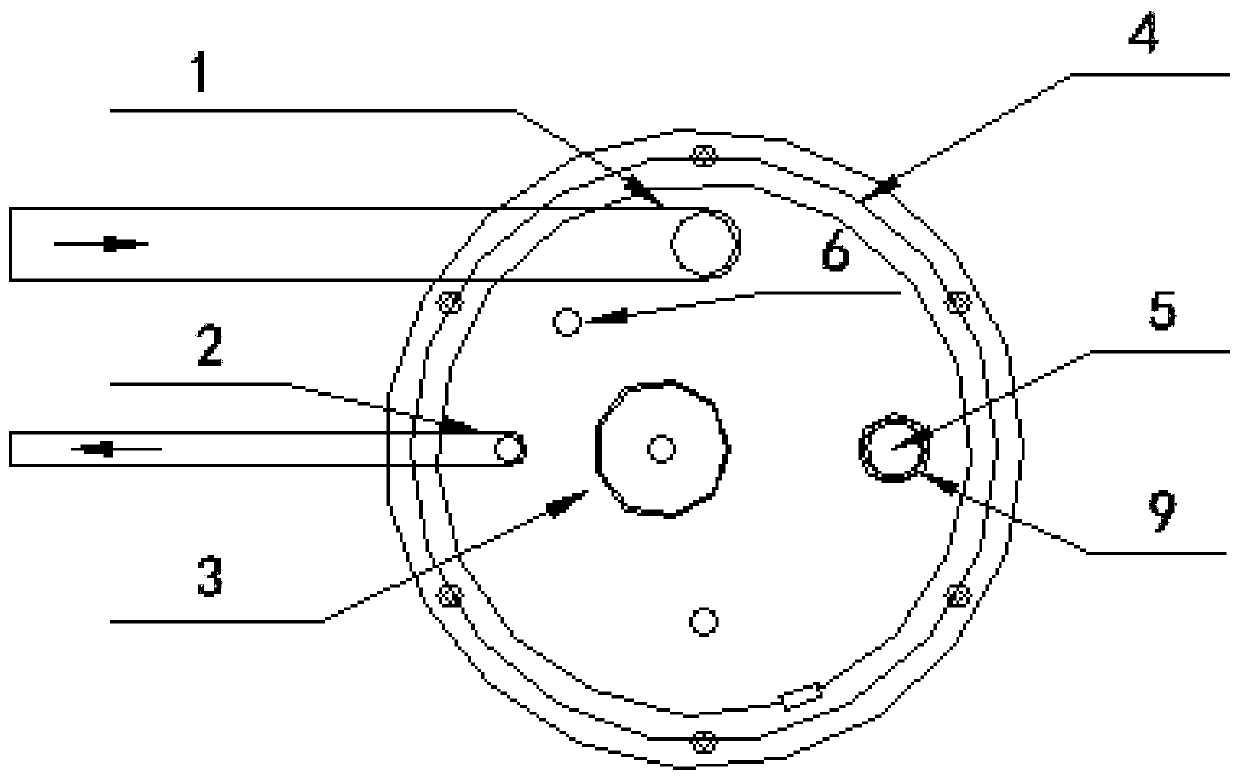

[0028] like figure 1 and figure 2 As shown, the present embodiment provides a kind of engine cylinder cavity electroplating equipment, is used for the electroplating of engine cylinder cavity, and this engine cylinder cavity electroplating equipment comprises the circulation pump 11 that connects in sequence, plating solution pumping pipe, frock Platform 14, plating solution inlet pipe 1, electroplating solution mother tank and liquid return pipe 2, the liquid inlet of the circulation pump 11 is connected with the liquid return pipe 2. The electroplating solution is circulated between the tooling platform 14 and the electroplating solution mother tank by the above-mentioned circulating pump 11, the above-mentioned plating solution pumping pipe, the plating solution inlet pipe 1 and the liquid return pipe 2 are the circulation pipelines of the electroplating solution, and the above-mentioned plating solution The model of the inlet pipe 1 is DN50PP, and the model of the liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com