Seasoning tea and production method and production equipment thereof

A technology for producing equipment and flavored tea, which is applied in chemical instruments and methods, tea, tea spices, etc., can solve the problems of low degree of aroma, weak and long-lasting aroma, achieve long-term and aroma effect, improve adsorption effect, Fragrant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1 discloses a kind of seasoning tea, and its raw material comprises the following components by weight:

[0071] 90kg of tea;

[0072] Edible essence 2kg;

[0073] Propylene glycol 120g.

[0074] The tea is made of fragrant oolong tea. Edible fragrance selects the honey peach essence with Banglong Industrial (Shanghai) Co., Ltd., and the model is CB201226.

[0075] The production method of the flavored tea that embodiment 1 provides, comprises the following steps:

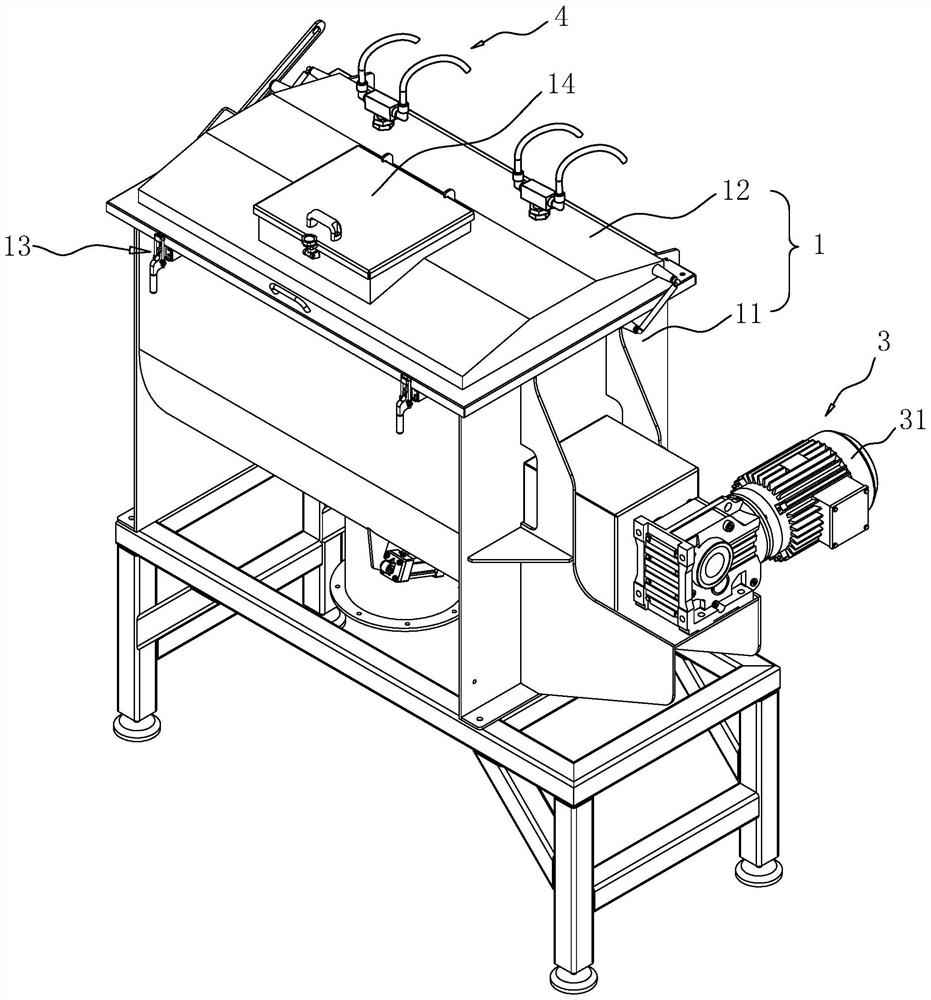

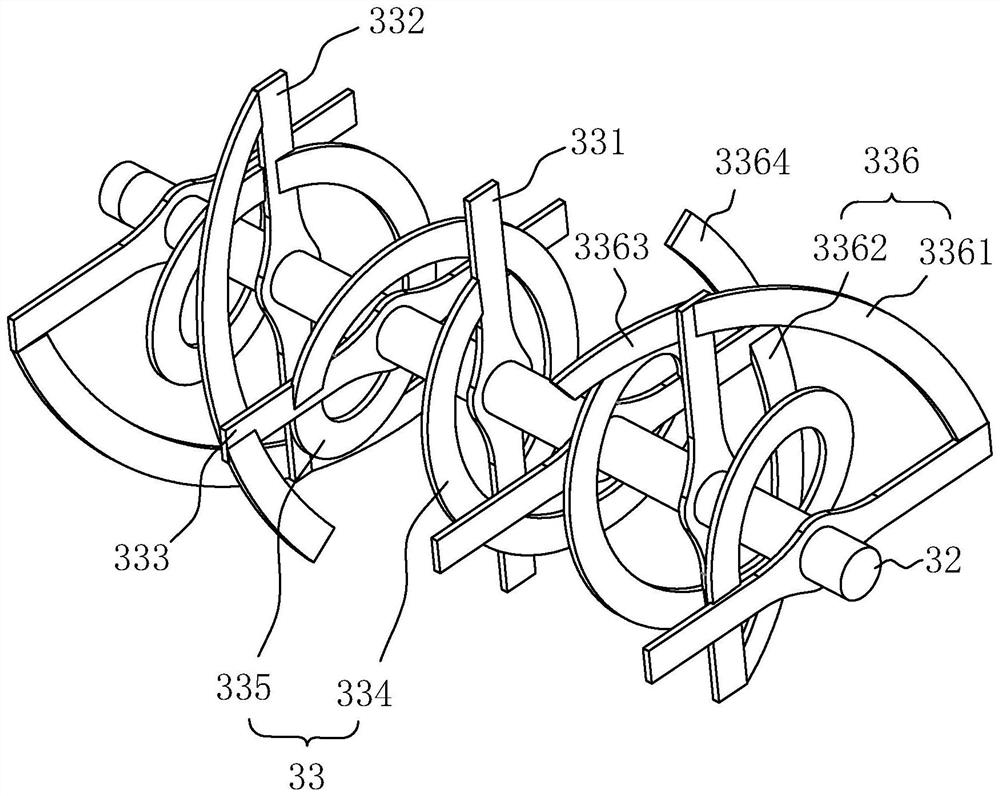

[0076] S1: Put 90kg of tea leaves into the flavored tea production equipment, heat the equipment to 45°C, and stir and dry the tea leaves at a speed of 100r / min for 10 minutes;

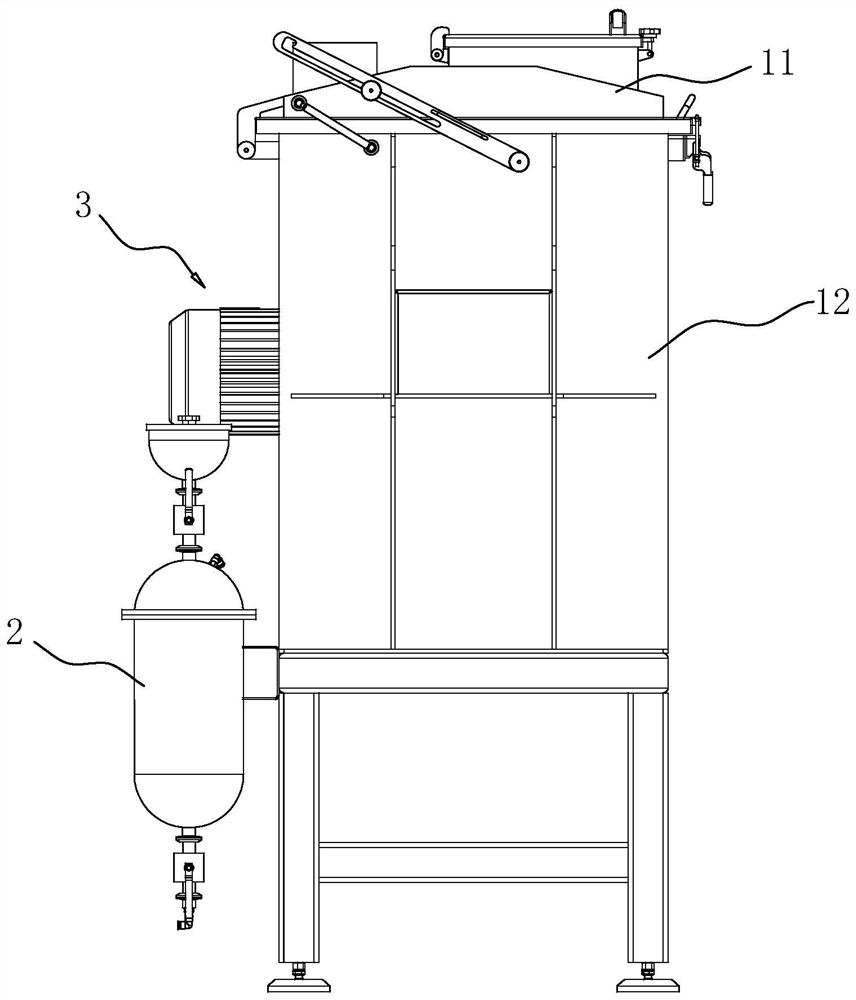

[0077] S2: First mix 2kg of food essence and 120g of propylene glycol in the aromatizing device evenly, then spray half the amount of food essence and propylene glycol mixture in the flavored tea production equipment, stop heating, and use the same temperature at the remaining temperature of step S1. Stirring speed c...

Embodiment 2-5

[0111] The difference with Example 1 is that the consumption of each component is different in the raw material of flavored tea, as shown in Table 1.

[0112] The consumption of each component in the raw material of table 1 seasoning tea

[0113] Example Tea (kg) Food flavor(kg) Propylene glycol (g) Example 2 92 4 120 Example 3 94 6 300 Example 4 96 8 640 Example 5 98 10 800

Embodiment 6-8

[0115] The difference with Example 1 is that in the preparation process of flavored tea, the temperature and time parameter settings in step S4 are different, as shown in Table 2.

[0116] Temperature and time parameter setting in step S4 of table 2

[0117] Example Holding temperature (℃) Holding time (min) Cooling temperature (℃) Example 6 40 20 32 Example 7 42 18 33 Example 8 44 14 35

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com