Polishing machine

A polishing machine and polishing device technology, applied in the field of polishing machines, can solve the problems of insufficient polishing, waste of manpower, financial resources and time, and low polishing efficiency, and achieve the effects of saving manpower and time, ensuring cleanliness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

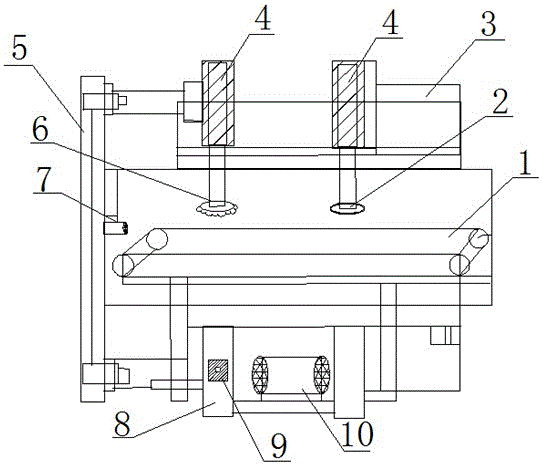

[0012] Such as figure 1 As shown, a kind of polishing machine of the present invention comprises driving device 10 and polishing device, and described polishing device is positioned at the top, is connected with driving device 10 by frame 5, and polishing device comprises polishing rotating shaft assembly 4, rough polishing disk 2 and the fine polishing disc 6, the rough polishing disc 2 and the fine polishing disc 6 are respectively connected with a polishing shaft assembly 4, a conveyor belt 1 is arranged below the polishing device, and the driving device 10 is installed on the base 8 under the conveyor belt, and the base 8 is provided with Drive switch 9, blower 7 is arranged at the place parallel to conveyer belt 1 inside frame 5, polishing rotating shaft assembly 4, conveyer belt 1 and blower 7 are all driven by driving device.

[0013] The invention has the advantages of simple structure, and provides a polishing machine with a rough polishing disc and a fine polishing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com