Adjustable industrial robot suitable for being used in mechanical production workshop

A technology of industrial robots and production workshops, applied in manipulators, grinding machine parts, manufacturing tools, etc., can solve problems such as the inability to meet work requirements and the inability to change the height of the grinding disc, and achieve multi-angle grinding and improve grinding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

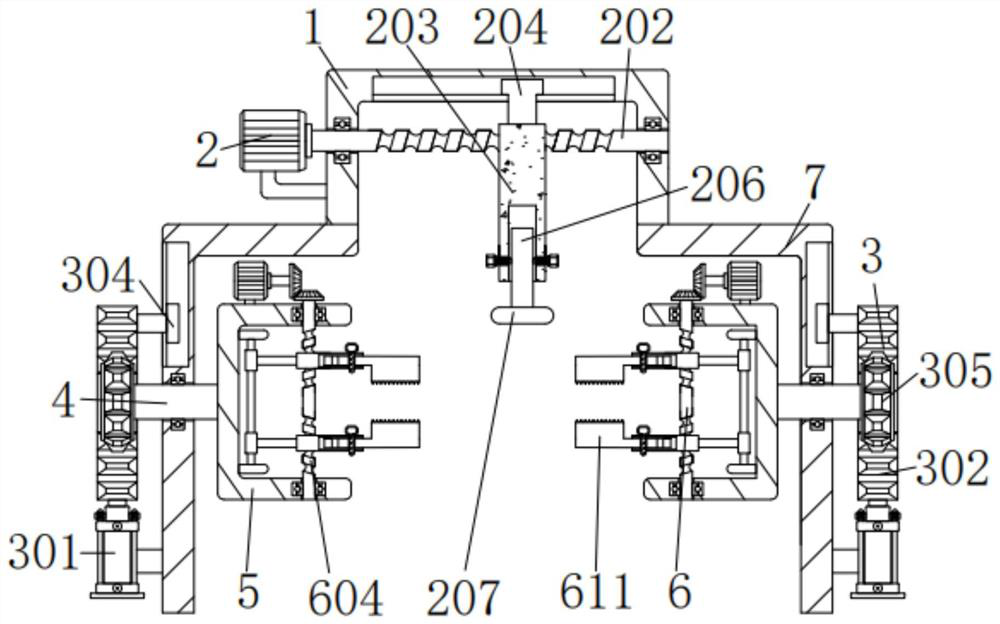

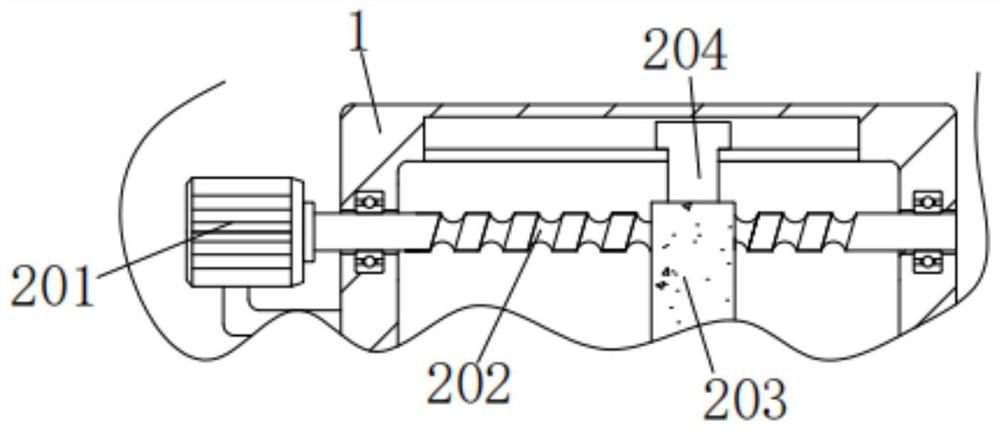

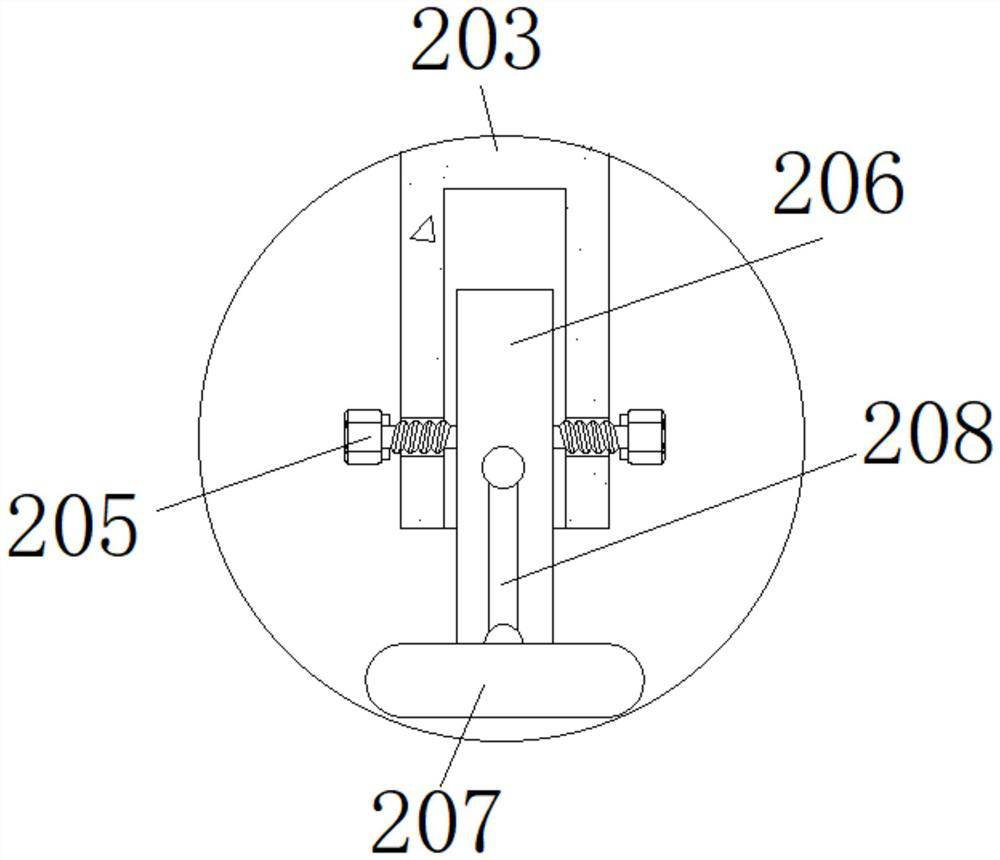

[0035]An adjustable industrial robot suitable for use in machinery production workshops, including a first shell 1 and a second shell 7, the bottom of the first shell 1 is connected to the second shell 7, and the upper part of the first shell 1 is provided with a mobile Device 2, mobile device 2 comprises first motor 201, screw rod 202, thick plate 203, first slide block 204, first bolt 205, vertical plate 206 and grinding plate 207, the bottom of first motor 201 passes bracket and first casing The left side of 1 is fixedly connected, the model of the first motor 201 is ECMA-E11320RS, the output end of the first motor 201 is fixedly connected with the left end of the screw rod 202, the output end of the first motor 201 can drive the screw rod 202 to rotate, the outer wall of the screw rod 202 The left and right sides are respectively connected to the upper left and right sides of the inner wall of the first shell 1 through bearings, the screw 202 can be rotated through the bear...

Embodiment 2

[0039] As an option, see figure 1 , 5 and 6 are suitable for industrial robots used in mechanical production workshops. The insides of the two third shells 5 are provided with clamping devices 6, and the clamping devices 6 include a second motor 601, a first bevel gear 602, a second bevel gear Shaped gear 603, stud 604, horizontal plate 605, thin rod 606, third slide block 607, slide bar 608, straight plate 609, second bolt 610 and wide plate 611, the model of the second motor 601 is ECMA-E11320RS , the bottom of the second motor 601 is fixedly connected to the top of the third housing 5 through a bracket, the output end of the second motor 601 is fixedly connected with the first bevel gear 602, and the second motor 601 can drive the first bevel gear 602 to rotate, The bottom of the first bevel gear 602 is meshed with the left side of the second bevel gear 603. When the first bevel gear 602 rotates, it can drive the second bevel gear 603 to rotate, and the bottom of the secon...

Embodiment 3

[0042] It is suitable for the application of industrial robots used in mechanical production workshops. When using the industrial robots suitable for use in mechanical production workshops, first place the steel pipe in the pre-clamping position, and unscrew the second bolt 610 if the clamping position needs to be changed , change the position of the wide plate 611, insert the second bolt 610 after changing the position and re-tighten it to meet the steel pipes of different lengths, at this time the second motor 601 is connected to the external power supply, the second motor 601 starts to work, the second motor 601 drives the first bevel gear 602 to rotate, the first bevel gear 602 drives the second bevel gear 603 to rotate through meshing, the second bevel gear 603 drives the double-ended stud 604 to rotate, and the double-ended stud 604 can drive The horizontal plate 605 and the wide plate 611 are close to each other to achieve clamping. After the clamping is completed, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com