Circuit breaker operation mechanism

A technology of operating mechanism and circuit breaker, applied in contact drive mechanism, high-voltage air circuit breaker, circuit, etc., to achieve the effect of simple structure, satisfying output requirements and adjustable output angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

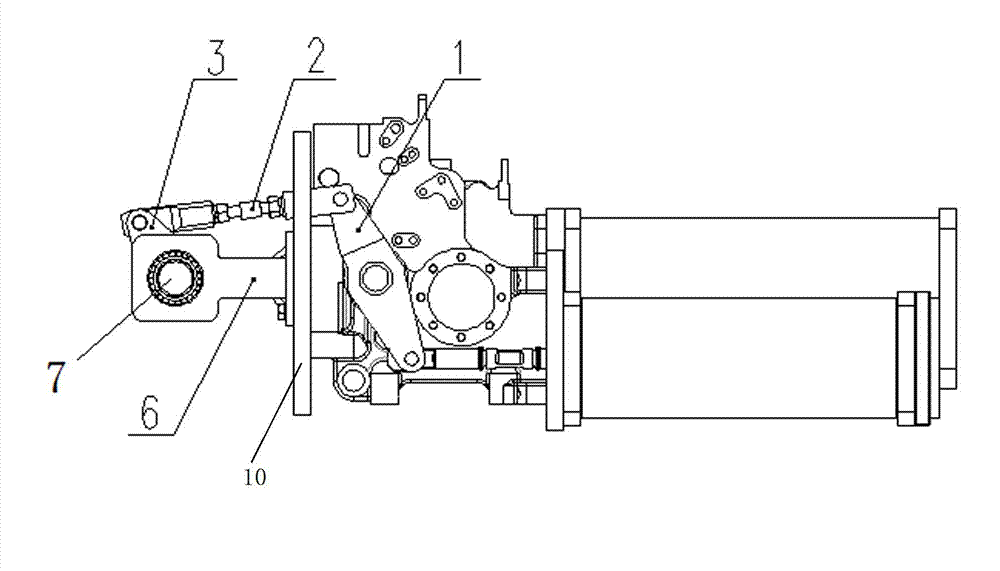

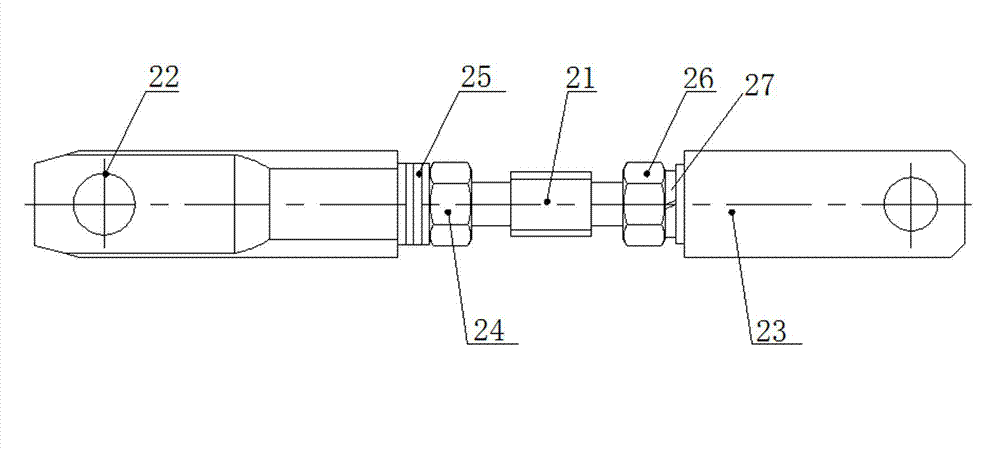

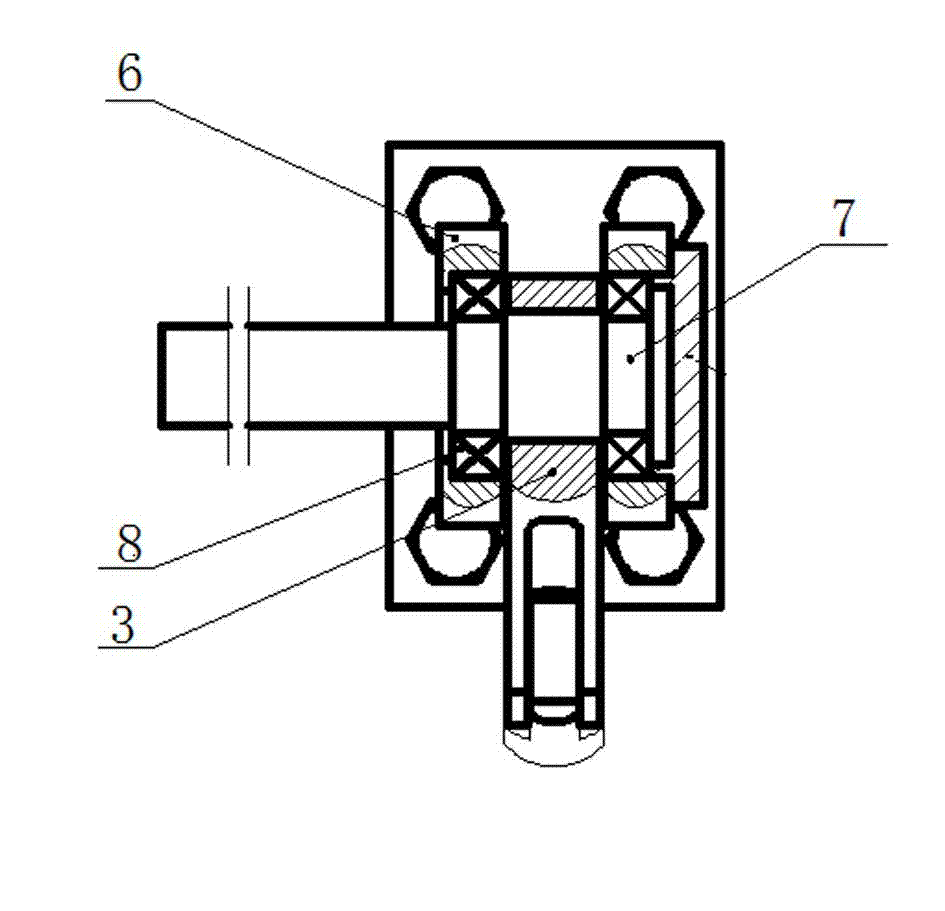

[0013] like figure 1 , figure 2 , image 3 As shown, an embodiment of a circuit breaker operating mechanism, the circuit breaker operating mechanism in this embodiment includes a mechanism chassis 10, on which the mechanism chassis 10 is rotatably equipped with a body crank arm 1, on which the mechanism chassis 10 is fixed A support 6 is installed, and a mechanism output shaft 7 is rotated on the support 6. The output shaft 7 of the mechanism is driven by the output crank arm 3 detachably installed on the support 6. The body crank arm 1 passes through the axial length The adjustable connecting rod 2 is in transmission connection with the output crank arm 3. The main body crank arm 1 forms a planar four-bar linkage mechanism through the axially adjustable connecting rod 2 and the output crank arm 3. The connecting rod 2 here consists of two axial The two ends of the connecting rod body 21 are respectively provided with connecting rod bodies 21 with opposite external threads,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com