Multifunction machining device of pipe fittings

A processing device and multi-functional technology, applied in the field of workpiece processing, can solve the problems of reduced polishing efficiency, trouble, waste of time, etc., and achieve the effects of compact structure, convenient use, and reduction of processing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

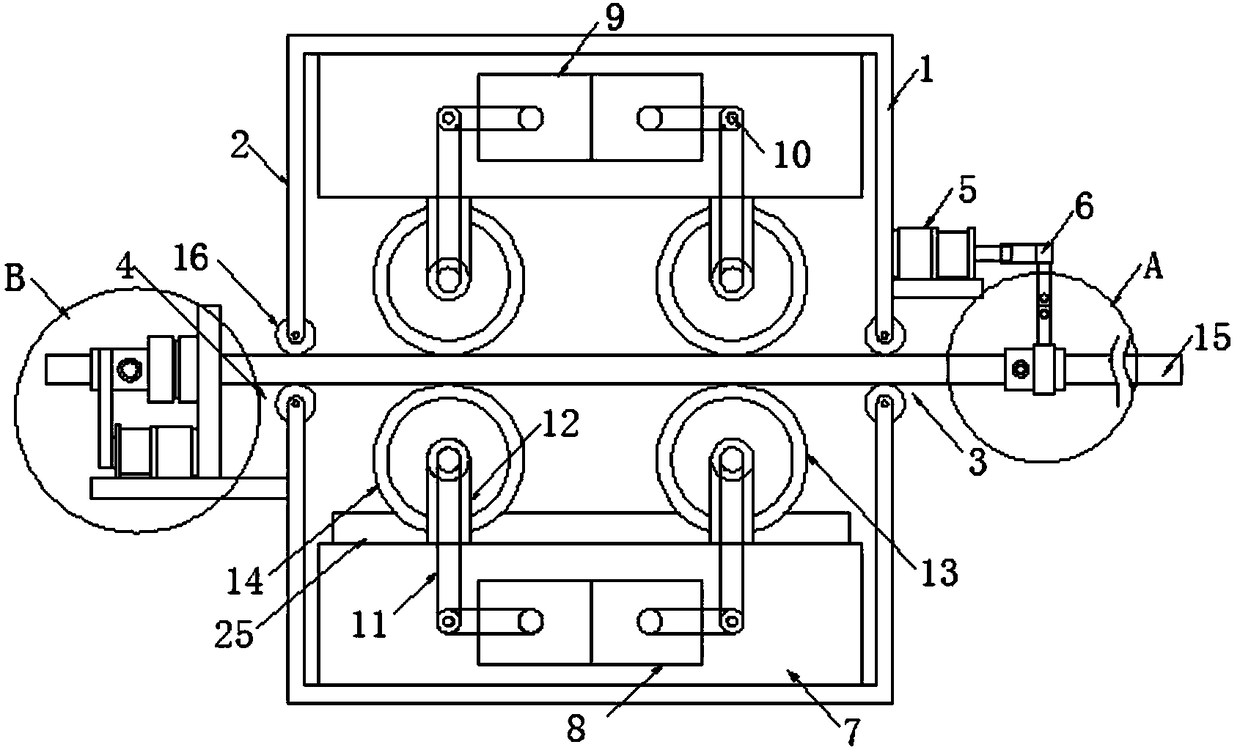

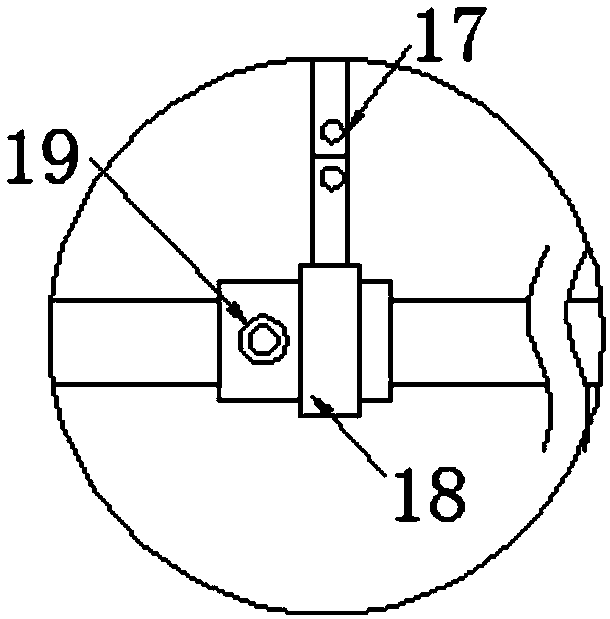

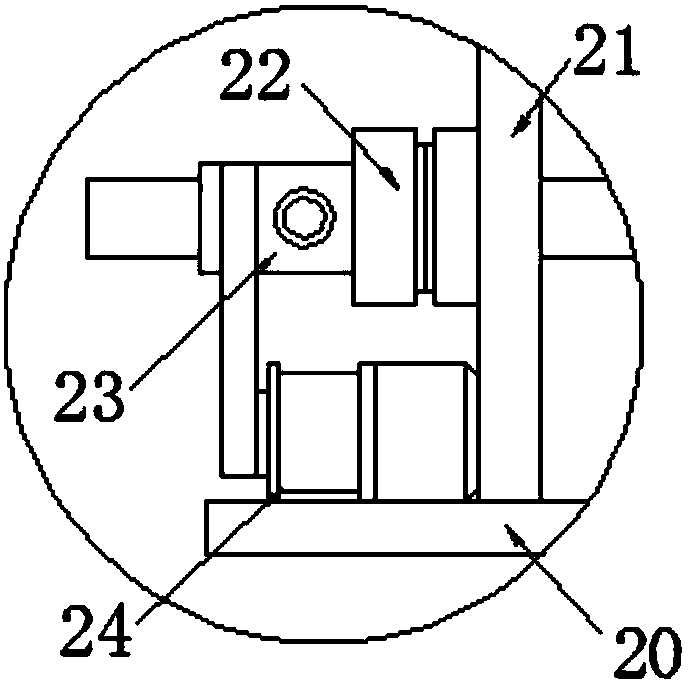

[0021] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a multifunctional processing device for pipe fittings, including a body 1, the body 1 includes support plates 2 arranged at both ends, and a feed inlet is opened between the support plates 2 at one end of the body 1 3. There is a discharge port 4 between the support plate 2 at the other end of the body 1, and pressure rollers 16 are installed on the support plate 2 at the upper and lower ends of the feed port 3 and the discharge port 4, and the feed port 3 and the discharge port 4 are connected by a pipe fitting 15, and the surface of the pipe fitting 15 is movably connected with the pressure roller 16. The support plate 2 on the side of the feed port 3 is fixedly installed with a traverse cylinder 5 through a mounting plate 20, and the traverse cylinder 5 is output through it. The piston rod 6 at the end is connected to the boom 17, and the bottom of the boom 17 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com