Pulverizer for ceramic production

A pulverizer and ceramic technology, used in clay preparation devices, grain processing, chemical instruments and methods, etc., can solve multiple problems such as grinding, poor grinding effect, and influence on ceramic processing and production, and achieve thorough grinding and structural Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

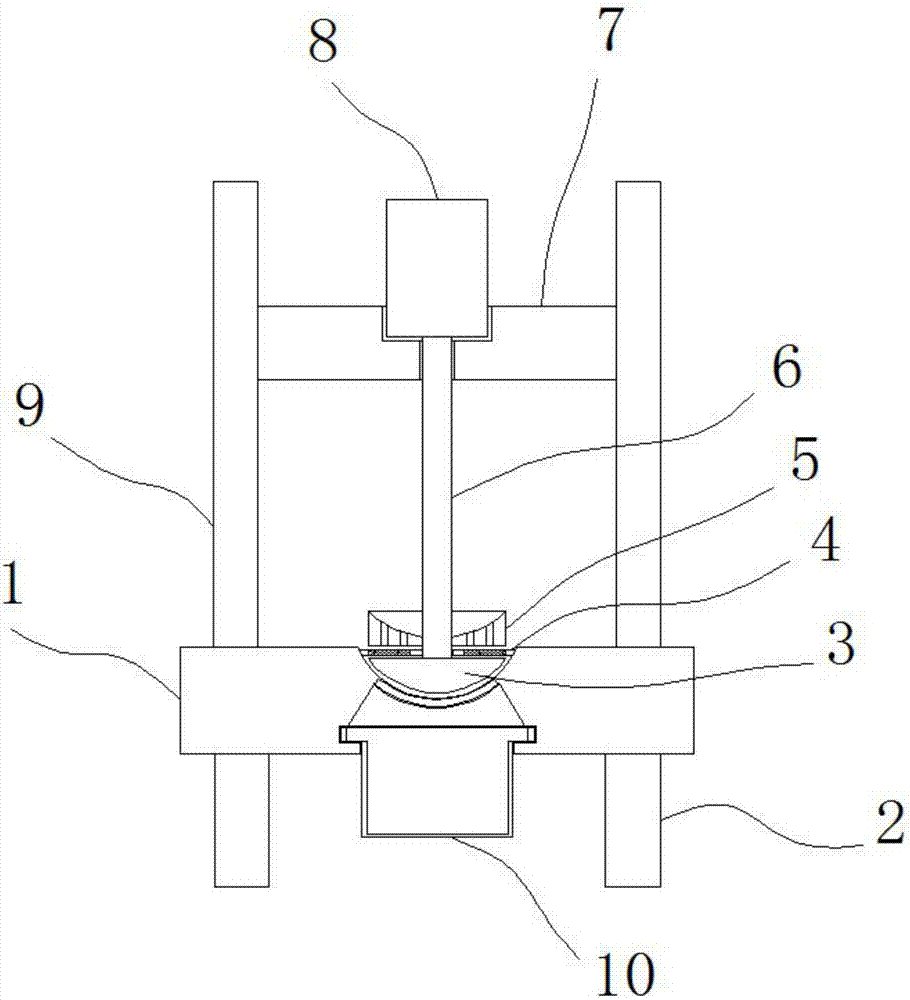

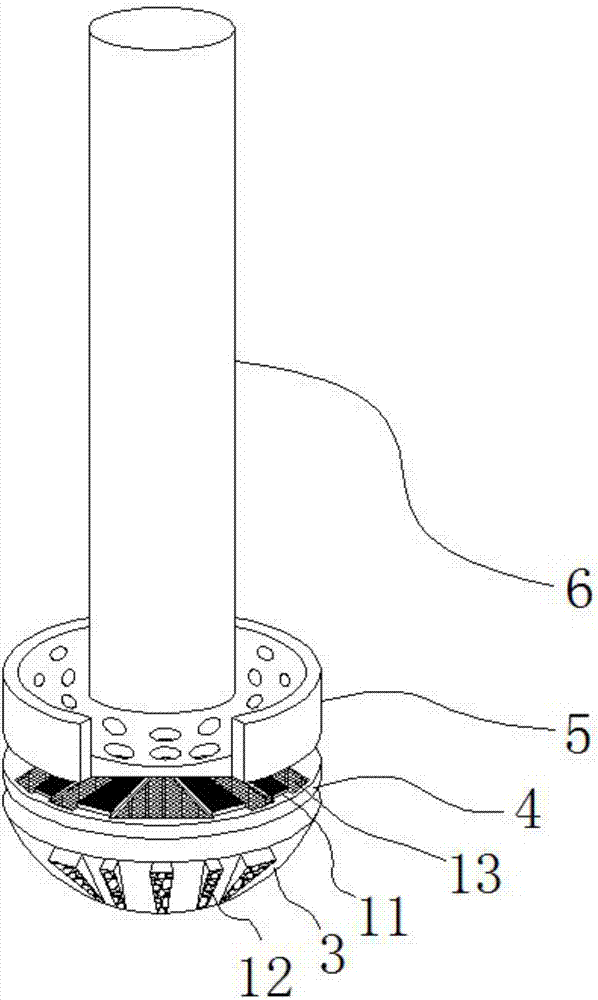

[0015] refer to Figure 1-2 , a mill for ceramic production, comprising a base plate 1, a base 2 is provided at the four corners below the base plate 1, and an anti-slip pad is provided on the bottom surface of the base 2 to increase the contact friction force of the bottom surface, so that the whole device is more stable during operation, Support rods 9 are symmetrically arranged vertically on both sides of the top of the base plate 1, and a cross bar 7 is arranged between the two support rods 9. A driving device 8 is installed on the cross rod 7, and a connecting rod 6 is connected to the driving end of the driving device 8. The rod 6 passes through the cross bar 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com