Transmission gear box for wheel type tractor

A technology for wheeled tractors and gearboxes, which is applied in the direction of gear transmissions, belts/chains/gears, mechanical equipment, etc., and can solve the problem that the transmission mechanism cannot realize multiple compound operations, cannot adapt to production needs and agronomic requirements, and single operation projects and working rotation to achieve the effect of reducing the use of parts, simplifying the structure, and facilitating maintenance and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

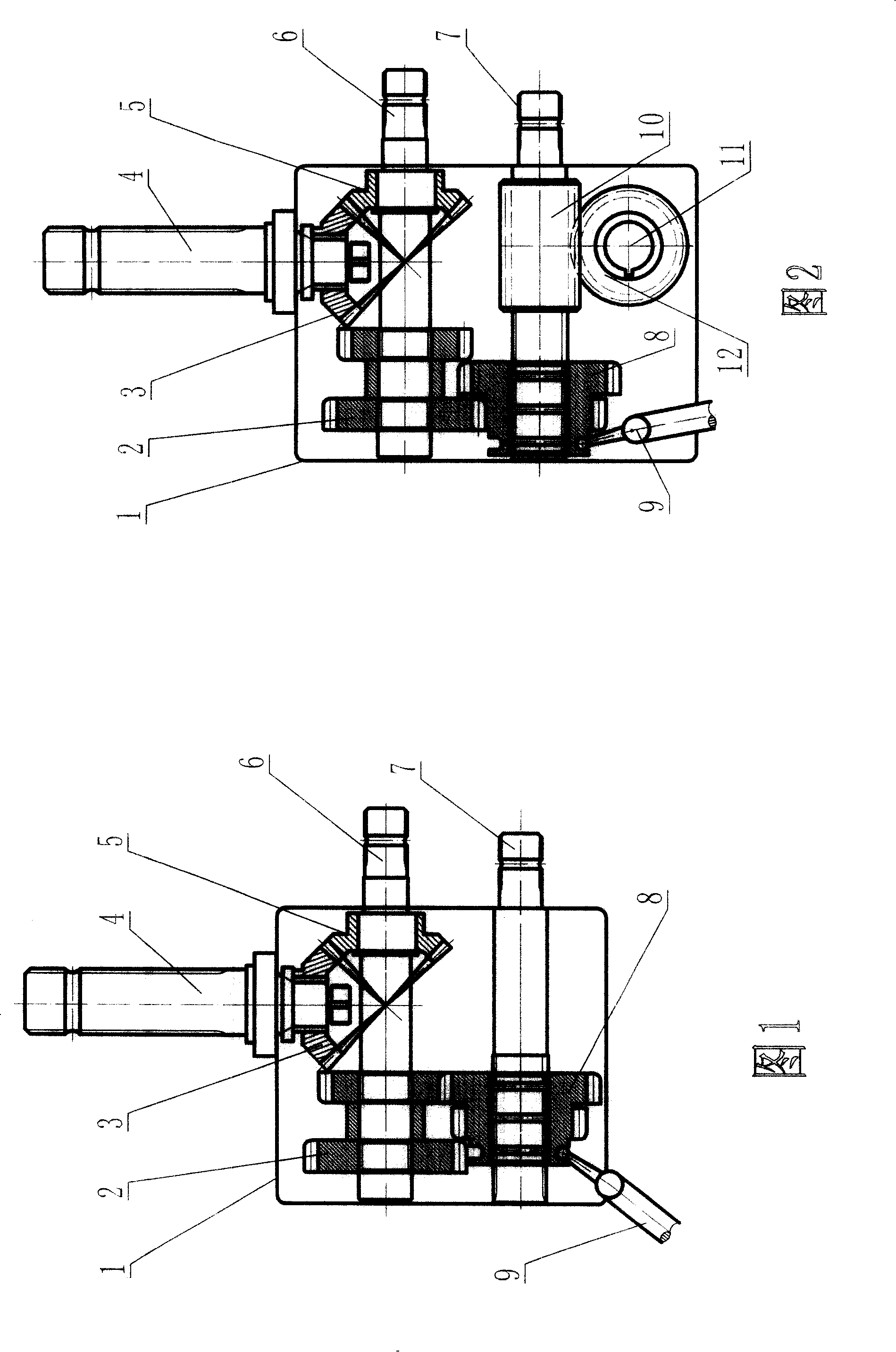

Embodiment 1

[0018] A gear box for a wheeled tractor, which includes a box body (1), an input shaft (4) erected on the box body (1), output shafts (6, 7), a toggle (9), and a set Bevel gear set (3,5), transition gear (2) and duplex gear (8) on the shaft. There are two output shafts, namely output shaft I (6) and output shaft II (7), output shaft I (6) and output shaft II (7) are arranged in parallel, and input shaft (4) is perpendicular to output shaft (6 , 7) Setting, the input shaft (4), the output shaft I (6) and the output shaft II (7) are in the same plane. The shaft ends on the same side of the output shaft I (6) and the output shaft II (7) protrude out of the casing (1) in the same direction. The bevel gear I (3) of the bevel gear set is set on the input shaft (4), the bevel gear II (5) is set on the output shaft I (6), and the two bevel gears (3, 5) mesh; the transition gear (2) It consists of two spur gears, the transition gear (2) is set on the output shaft I (6); the duplex ge...

Embodiment 2

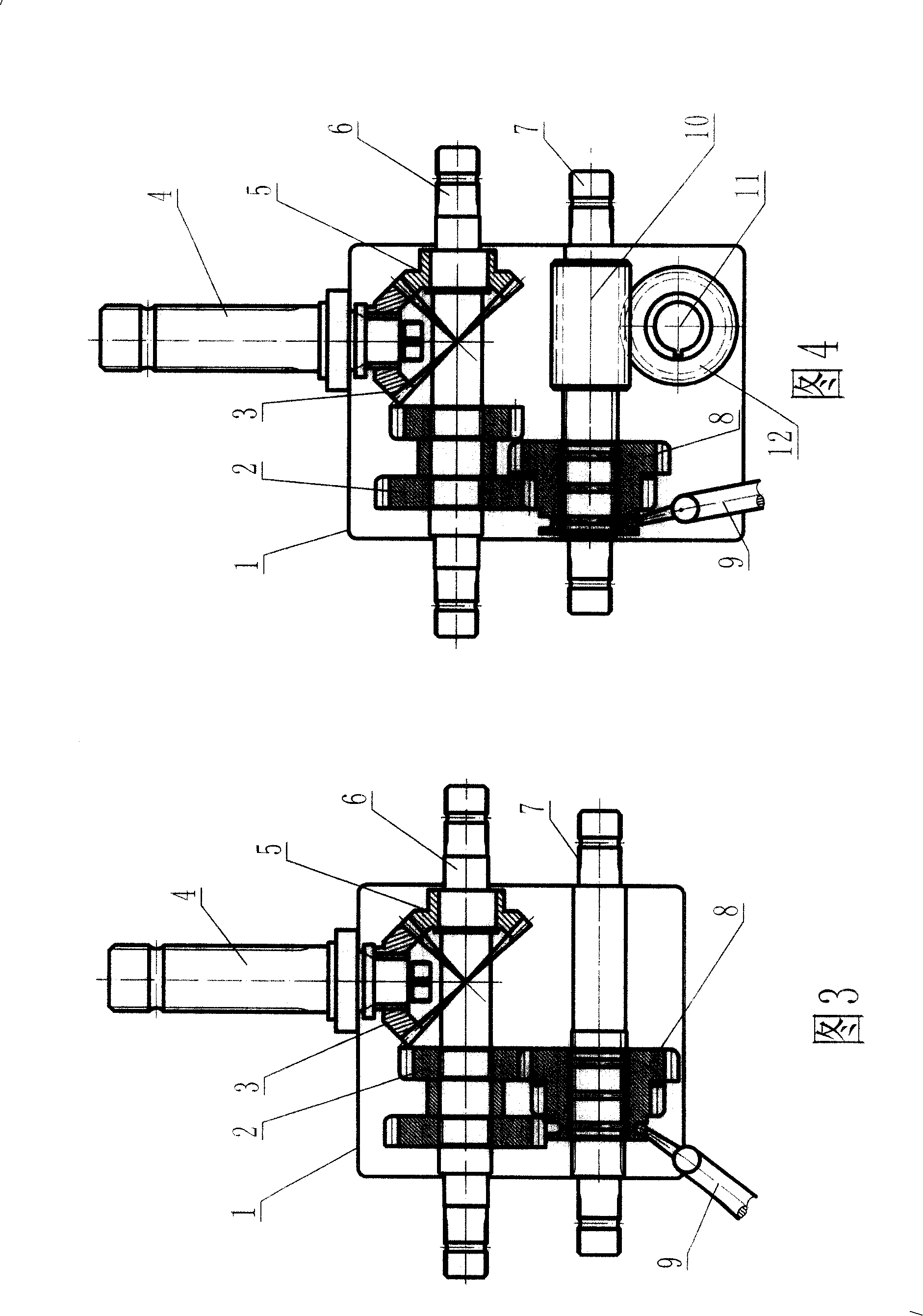

[0020] A gear box for a wheeled tractor, which includes a box body (1), an input shaft (4) erected on the box body (1), output shafts (6, 7, 11), and a toggler (9), And bevel gear set (3,5), transition gear (2), duplex gear (8), worm gear (12) that are arranged on the shaft. There are three output shafts, namely output shaft I (6), output shaft II (7) and output shaft III (11), output shaft I (6) and output shaft II (7) are arranged in parallel, input shaft (4) It is arranged perpendicular to the output shafts (6, 7), and the input shaft (4), output shaft I (6) and output shaft II (7) are in the same plane. The shaft ends on the same side of the output shaft I (6) and the output shaft II (7) protrude out of the casing (1) in the same direction. The bevel gear I (3) of the bevel gear set is set on the input shaft (4), the bevel gear II (5) is set on the output shaft I (6), and the two bevel gears (3, 5) mesh; the transition gear (2) It consists of two spur gears, the transiti...

Embodiment 3

[0023] A gear box for a wheeled tractor, which includes a box body (1), an input shaft (4) erected on the box body (1), output shafts (6, 7), a toggle (9), and a set Bevel gear set (3,5), transition gear (2) and duplex gear (8) on the shaft. There are two output shafts, namely output shaft I (6) and output shaft II (7), output shaft I (6) and output shaft II (7) are arranged in parallel, and input shaft (4) is perpendicular to output shaft (6 , 7) Setting, the input shaft (4), the output shaft I (6) and the output shaft II (7) are in the same plane. Both ends of the output shaft I (6) and the output shaft II (7) are stretched out of the casing (1). The bevel gear I (3) of the bevel gear set is set on the input shaft (4), the bevel gear II (5) is set on the output shaft I (6), and the two bevel gears (3, 5) mesh; the transition gear (2) It consists of two spur gears, the transition gear (2) is set on the output shaft I (6); the double gear (8) is set on the output shaft II (7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com