Bowl-shaped ornament polishing machine

A polishing machine and jewelry technology, which is applied to surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of uneven surface, high labor intensity and high production efficiency of hand-polished bowl-shaped jewelry. Low-level problems, to save resources, reduce labor intensity, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

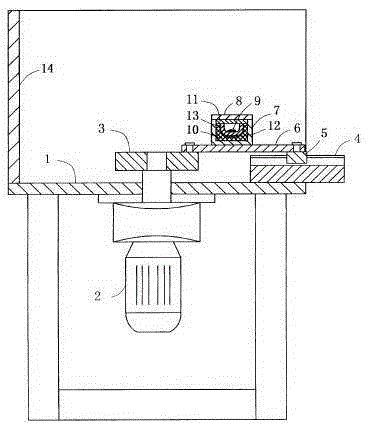

[0012] like figure 1 As shown, a bowl-shaped jewelry polishing machine mainly includes a frame 1, a turntable 3 driven by a power device, a linear slideway 4, a connecting rod 6, and a grinding barrel body 7 and a barrel cover 8 connected together. Wherein, the power device is preferably a motor reducer 2; the turntable 3 is rotatably mounted on the frame 1, and can be fixed directly on the output shaft of the motor reducer 2 according to actual conditions; the linear slideway 4 is fixedly installed on the frame 1; one end of the connecting rod 6 is hinged on the turntable 3, and the other end is constrained in the linear slideway 4, usually, a slider 5 is slidably installed in the linear slideway 4 , one end of the connecting rod 6 is hinged on the slider 5; the grinding barrel body 7 is fixedly mounted on the connecting rod 6, and the connection mode of the grinding barrel body 7 and the barrel cover 8 can adopt common snapping, locking or Screw connection and other ways, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com