Automatic chip cleaner of full-functional machine tool

A full-featured, automatic discharge technology, applied in the direction of conveyors, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of not being able to complete the chip conveying work independently, not being able to equip a chip removal machine, and not being able to push the movement, etc., to achieve reduction The effect of non-effective working time, production site civilization, and effective working time increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

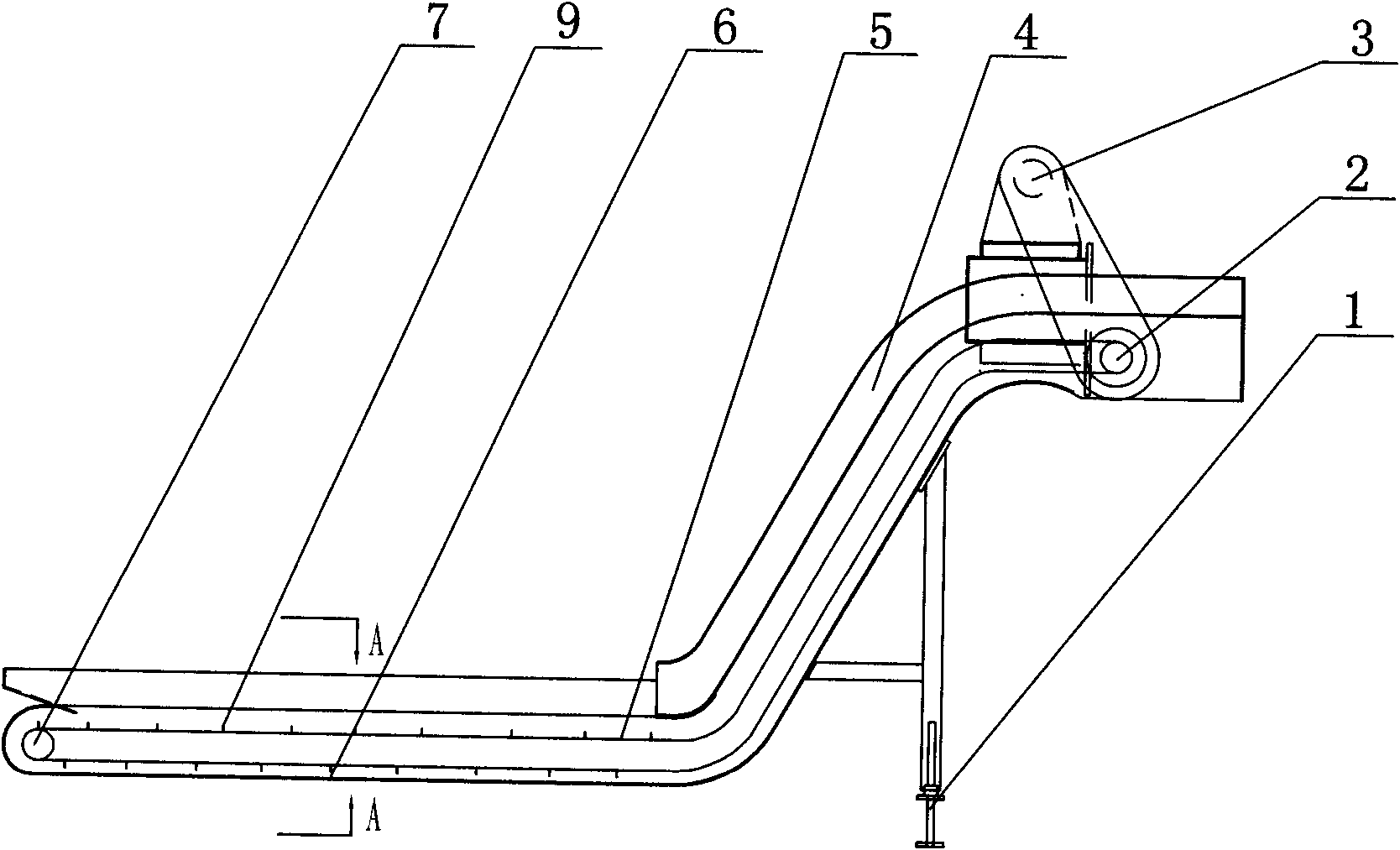

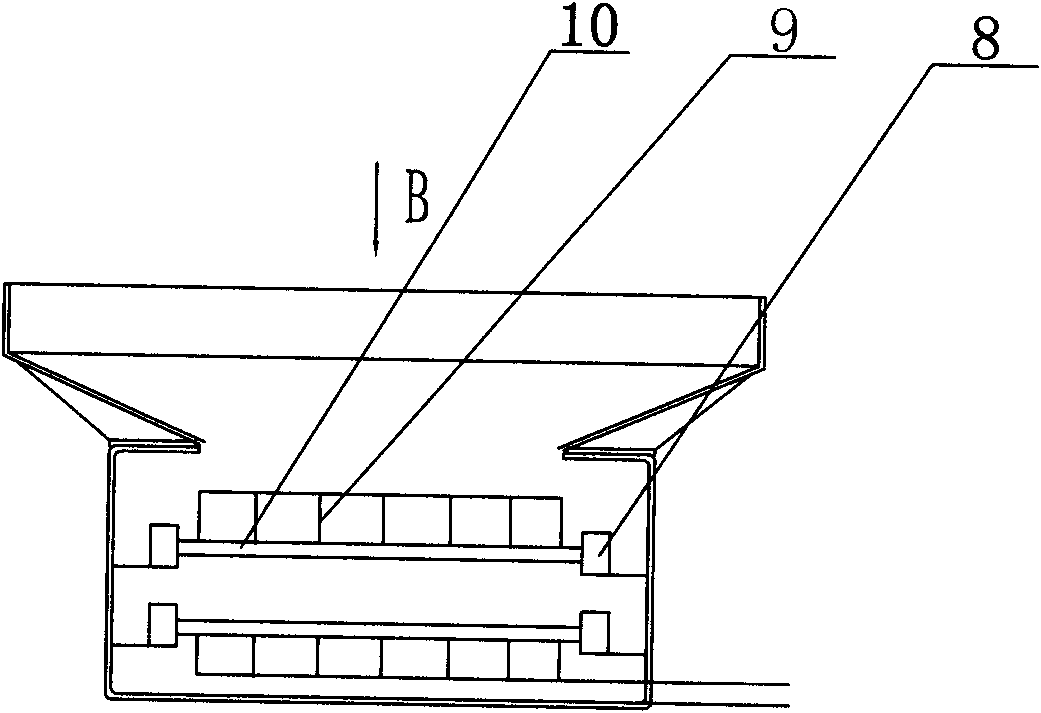

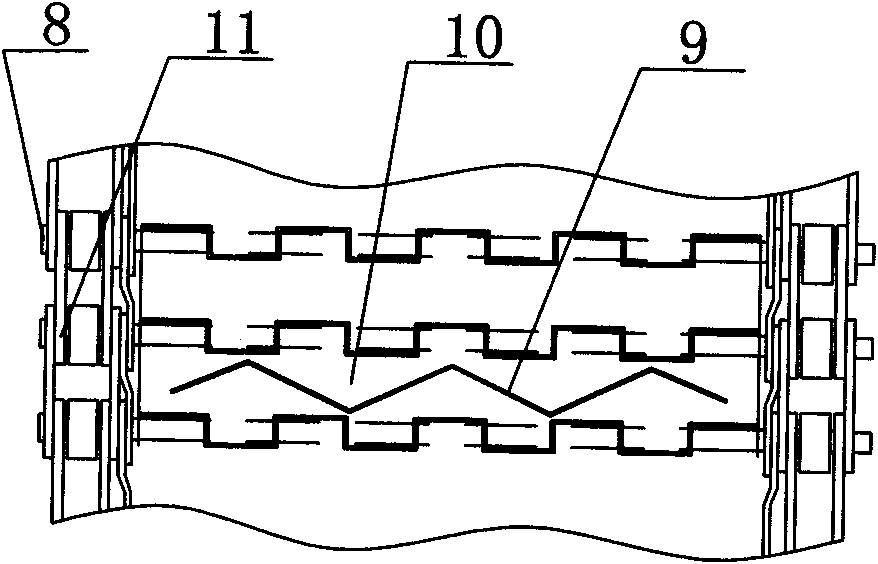

[0026] The present invention comprises frame 4, and motor 3 links to each other with drive shaft 2 above frame 4, and between drive shaft 2 and supporting shaft 7 below frame 4 is chain plate conveyer belt 5, and chain plate conveyer belt 5 is made of chain plate 10, chain 11. Composed of pin shafts 8, the chain plate 10 is connected in the form of a hinge plate through the pin shaft 8; the outside of the frame 4 is an adjustable foot 1, and the chain plate 10 is provided with a W-shaped chip pusher 9, and the W-shaped chip pusher Plate 9 is perpendicular to chain plate 10 .

[0027] The W-shaped chip pusher 9 is welded on the chain plate 10 by welding; the use of the W-shaped chip pusher 9 will not squeeze the chips to both sides, but will push the chips to the middle instead. In this way, there will be no situation where the chip pushing resistance will be increased after the chips are squeezed.

[0028] In order to make the present invention produce better chip removal eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com