T-shaped railway turnout maintenance tool

A technology for maintenance tools and turnouts, applied in track cleaning, construction, cleaning methods, etc., can solve problems such as insecurity and low efficiency, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

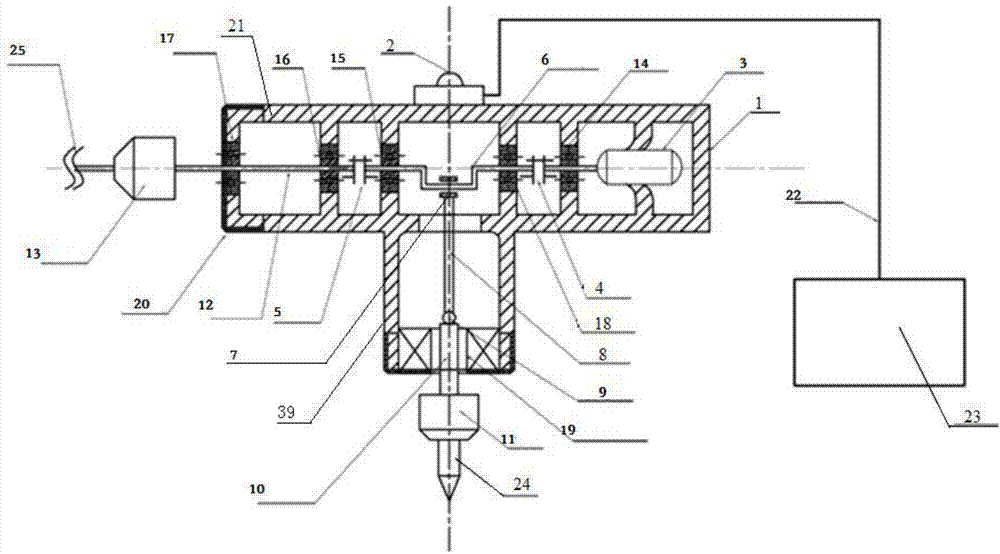

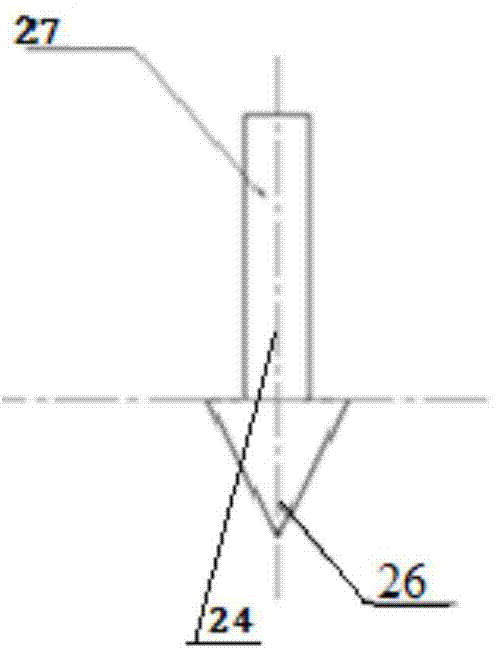

[0030] T-shaped railway switch maintenance tool of the present invention comprises maintenance tool main body and tool head, wherein, the structure of maintenance tool main body, as figure 1 As shown, it includes a T-shaped split casing 1, one end of the transverse part of the T-shaped split casing 1 is a horizontal working end 21, and the longitudinal part of the T-shaped split casing 1 is a longitudinal working end 39, two The centerlines of the working ends are perpendicular to each other.

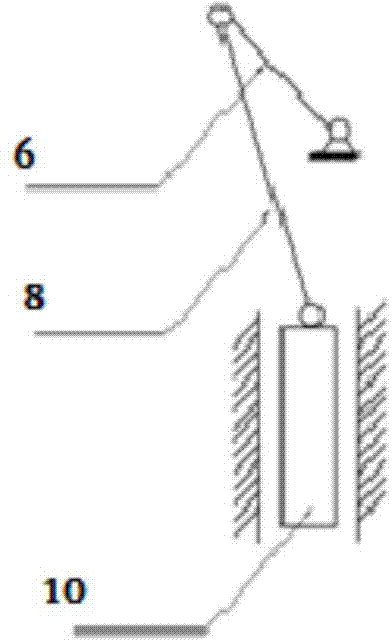

[0031] A motor 3 is installed in the T-shaped split casing 1, the motor 3 is connected with one end of the crankshaft 6 through the first coupling 4, and the other end of the crankshaft 6 is connected with one end of the rotating shaft 12 through the second coupling connection; the other end of the rotating shaft 12 stretches out from the transverse w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com