Two joint type online cleaning robot for condenser copper tube

A technology for cleaning robots and condensers. It is applied in the direction of manipulators, cleaning heat transfer devices, and non-rotating equipment cleaning. It can solve the problems of inability to clean copper pipes and withstand the impact of circulating water, etc., and achieve good cleaning effect and high degree of automation. , good structure and performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

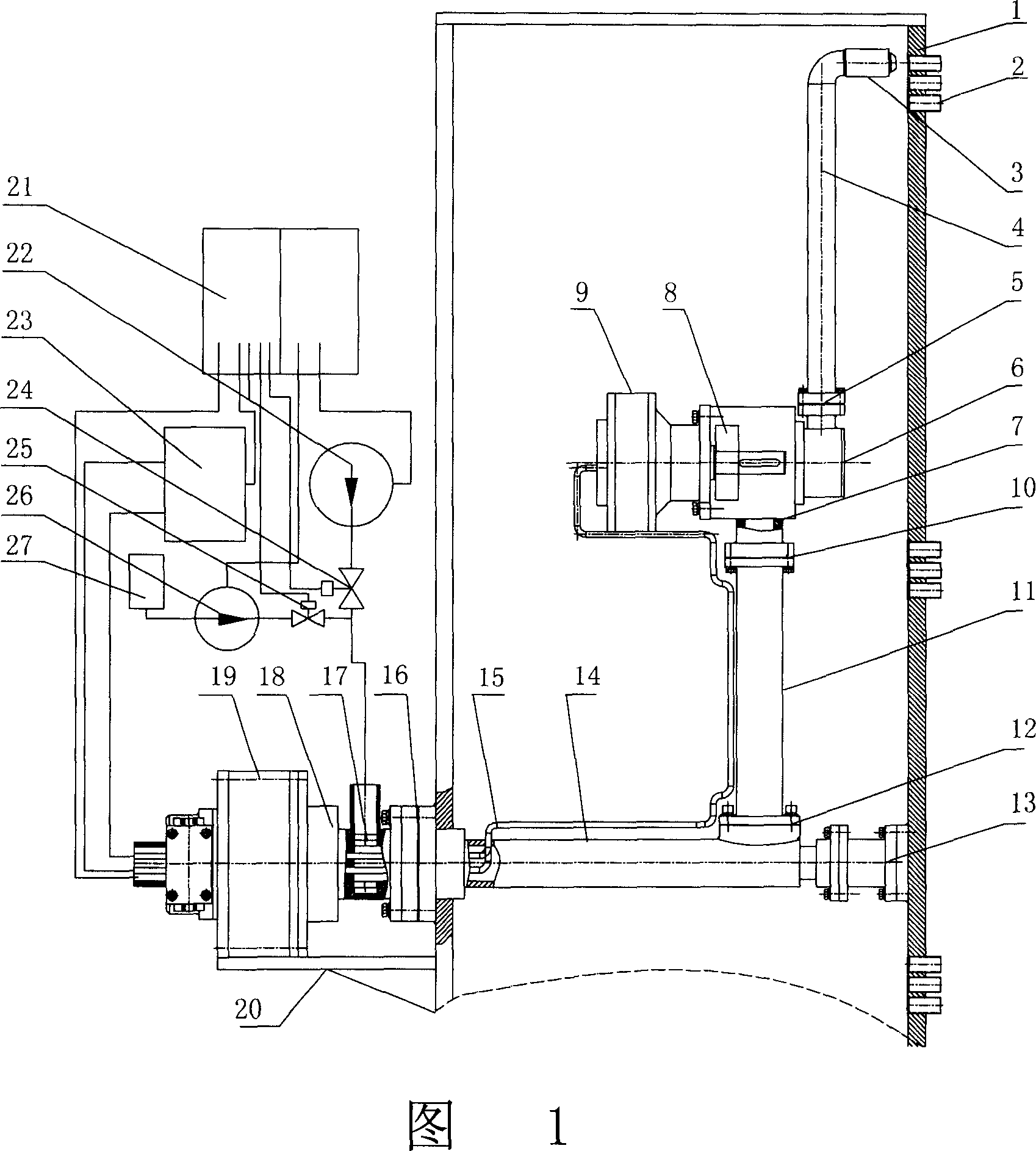

[0026] As shown in Figure 1, the two-joint online cleaning robot for condenser copper tubes of the present invention includes a nozzle 3, a small arm 4, a rotating water chamber 6, a rotary encoder 8, a small arm hydraulic driver 9, a large arm 11, and a rotating handle. Arm 14, water inlet chamber 17, large arm hydraulic driver 19, bracket 20 and control mechanism, wherein the rotating crank arm 14 is arranged in the condenser water chamber 28, and is connected to the outer wall of the condenser water chamber 28 through the water outdoor support assembly 16 , and is connected to the inner wall of the condenser water chamber 28 through the support assembly 13 in the water chamber. Using this kind of bearing hard support can not only make the rotating crank arm 14 rotate freely, but also ensure firmness and reliability, and can avoid the impact caused by high w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com