Steel rail grinding equipment

A technology for rails and equipment, applied in the field of rail grinding equipment, can solve the problems of inconvenient operation, transportation and placement, large self-vibration, unfavorable wave grinding, etc., and achieves the effect of improving the grinding range, reducing the adverse effects and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

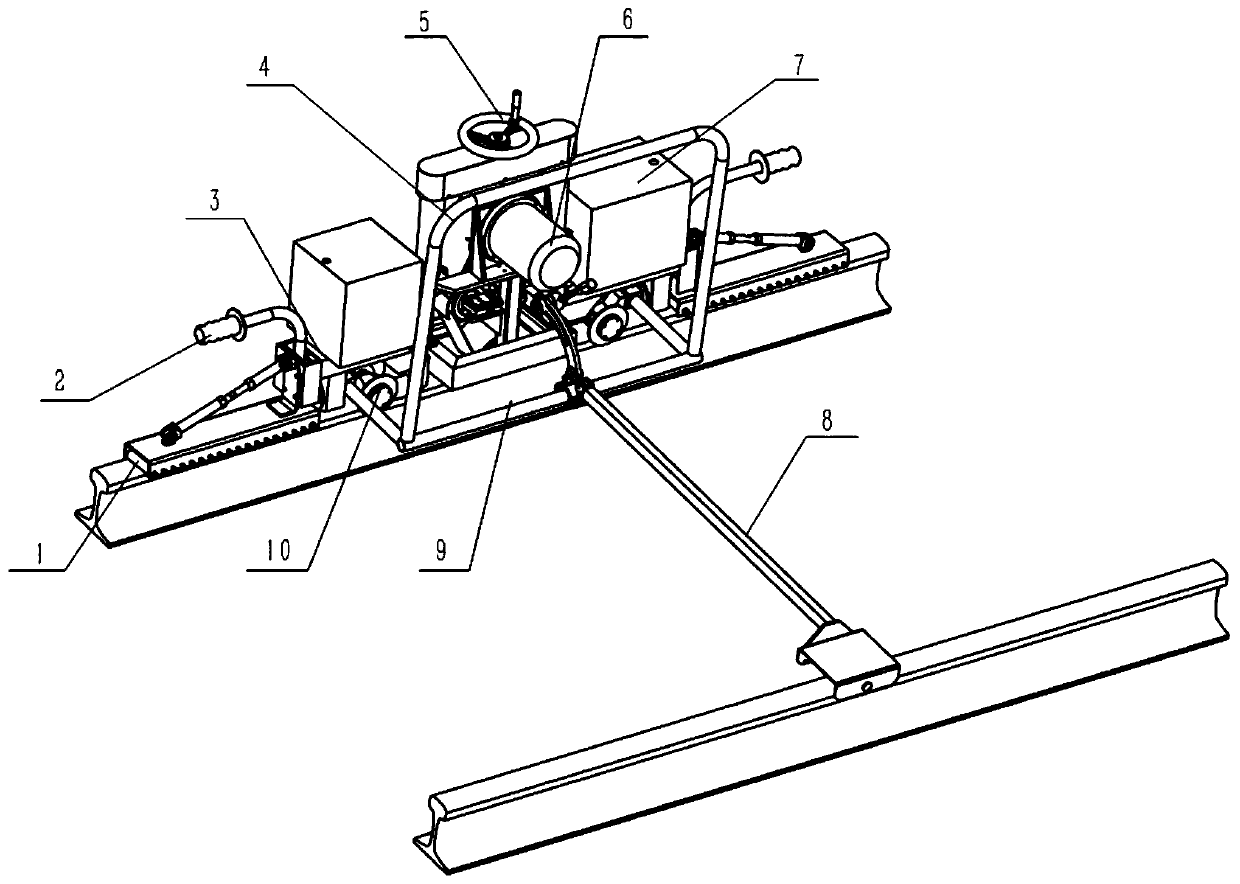

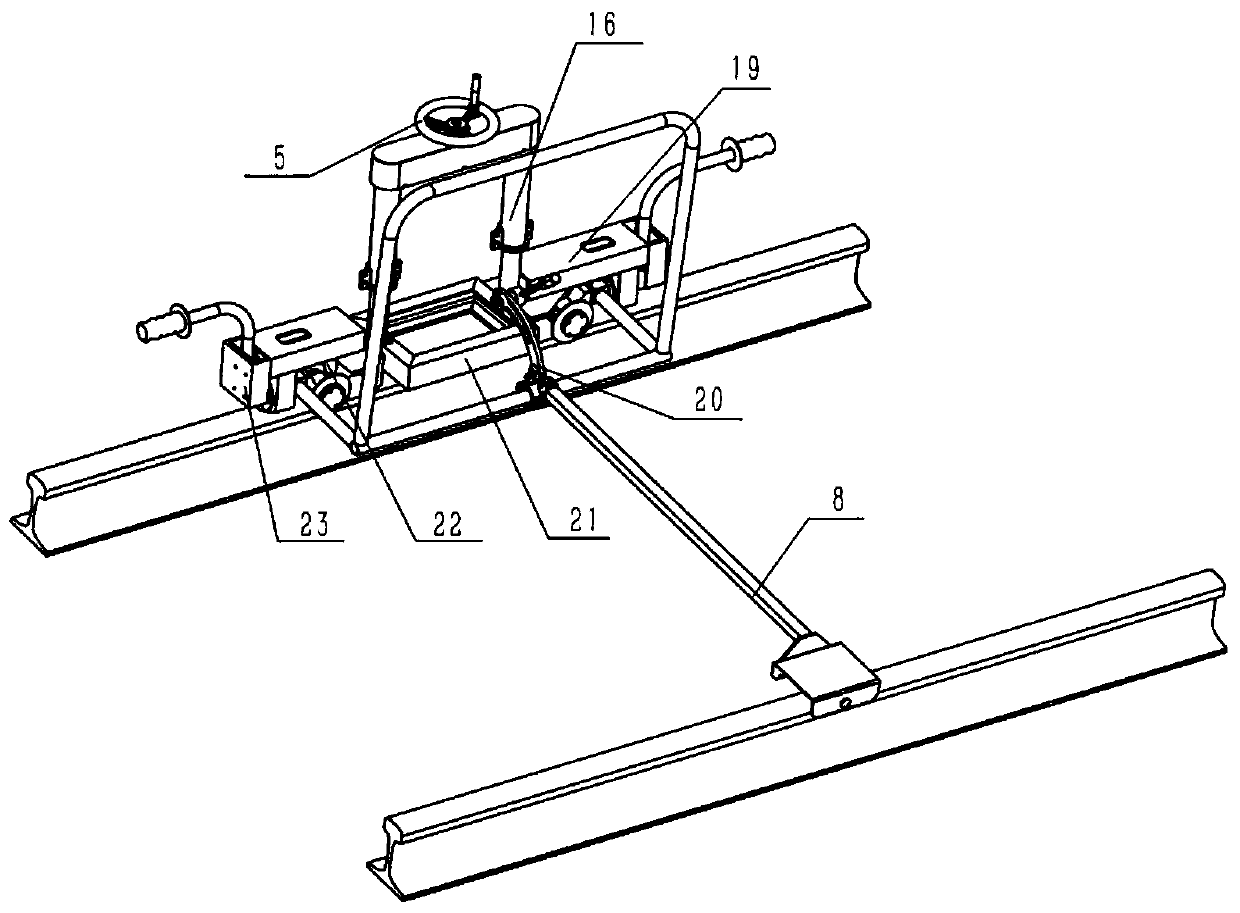

[0049] In order to realize the installation (or connection) between the sanding belt grinding device and the frame 9 (or specifically with the column 16), an arm extending horizontally from the column 14 to both sides (for example Figure 5 The element represented by 18 in ), the arm is provided with a connection structure 40, so that the abrasive belt grinding device is fixed or movably mounted on the column 16 in various possible ways such as fastening, snapping, surrounding, riveting and the like. Such as image 3 with 5 As best shown, the connecting structure 40 may be configured as two parts, both of which are of a semicircular configuration and capable of enclosing the post 16 therein when connected to each other.

no. 2 example

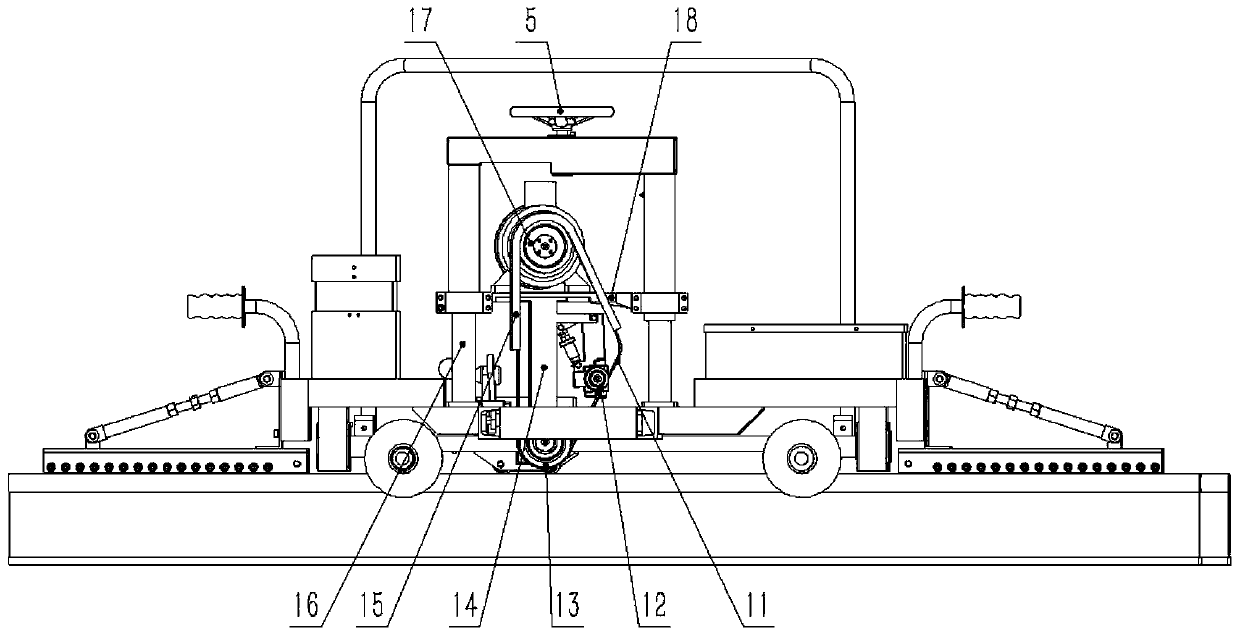

[0051] In order to realize that the abrasive belt grinding device can move in the height direction relative to the steel rail, the abrasive belt grinding device further includes a lifting mechanism.

[0052] The lifting mechanism can at least drive the contact wheel 13 to move in the height direction (up and down). Alternatively, the lifting mechanism can drive the whole abrasive belt grinding device (including the abrasive belt 11, the driving wheel 17, the tensioning wheel 12 and the contact wheel 13) to move in the height direction. Since the above two movable connection modes are similar, here only the lifting mechanism drives the abrasive belt grinding device to move as a whole as an example for illustration. Those skilled in the art can think of other ways on this basis.

[0053] see Image 6 , in the illustrated embodiment, the lifting mechanism can drive the drive wheel 17, the tension wheel 12, the contact wheel 13 and the abrasive belt 11 on it to lift up and down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com