Linkage dustproof plate arc edge and flat edge integrated grinding device

A dust-proof and plate technology, which is applied in the direction of grinding/polishing safety devices, grinding machines, grinding workpiece supports, etc., can solve the problems of easily generating dust that affects the health of operators and low grinding efficiency, so as to avoid plate pollution and harm to the human body damage, improve grinding efficiency, and prevent dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

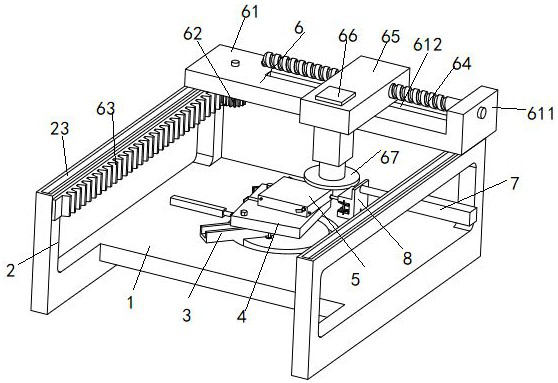

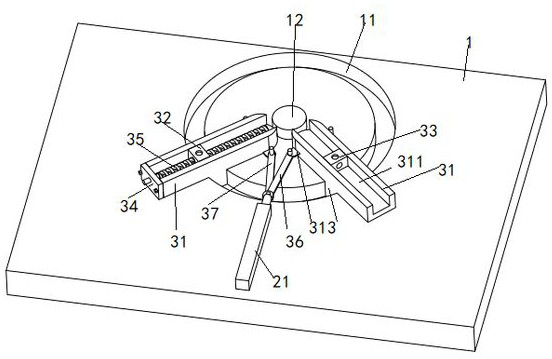

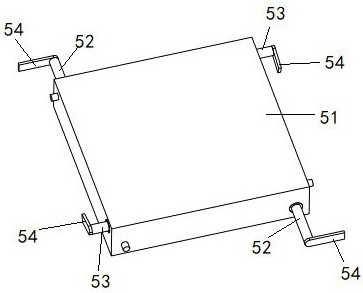

[0026] A linked dust-proof plate arc edge and flat edge integrated grinding device, such as Figure 1-5 As shown, the grinding platform 1 is included, and the vertical fixing of the grinding platform 1 is provided with two opposite support limit plate frames 2. An angle adjustment mechanism 3 is installed, and a support plate 4 is installed in a sliding fit on the angle adjustment mechanism 3. The first reduction motor is installed in the middle of the surface of the support plate 4, and a fixed displacement mechanism 5 is installed on the power output end of the first reduction motor. The polished plate is fixed on the fixed displacement mechanism 5; the top of the two supporting limit plate frames 2 is equipped with a steering transmission mechanism 6, and the plate to be processed is transmitted to the fixed displacement mechanism 5 through the steering transmission mechanism 6 for processing. A grinding adjustment hydraulic cylinder 7 is installed in the middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com