Modified epoxy-phenolic high-temperature thermal recovery surface pipeline

A technology for epoxy phenolic and ground pipelines, applied in rigid pipes, epoxy resin coatings, pipes, etc., can solve problems such as low production efficiency, complicated steps, and substandard pipeline quality, so as to improve production efficiency, simple operation, suitable for The effect of promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

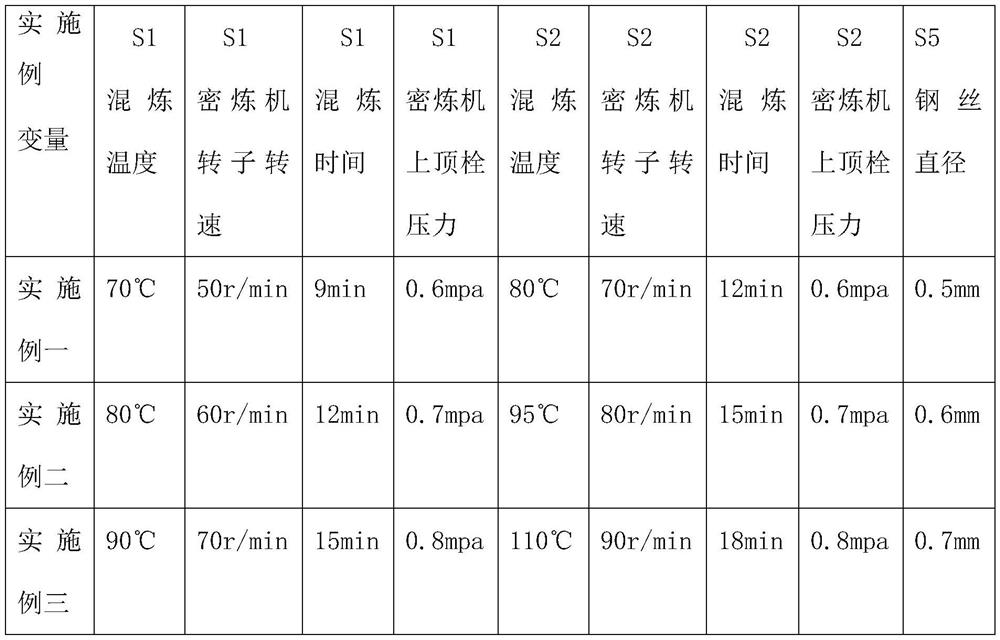

Embodiment 1

[0029] Embodiment 1: A modified epoxy phenolic high-temperature thermal recovery surface pipeline, the pipeline is composed of an outer coating, an outer rubber layer, a skeleton layer, an inner rubber layer and an inner coating, and the outer coating and the inner coating have the same composition. Its preparation process includes the following steps: S1, the first mixing: put the corresponding number of inner rubber layer raw materials into the internal mixing chamber of the internal mixer for mixing, after mixing, the inner rubber layer colloid is obtained, and the mixing temperature is 70°C. The rotor speed of the internal mixer is 50 / min, the mixing time is 9min, and the top bolt pressure of the internal mixer is 0.6mpa; repeat the above steps to mix the raw materials of the outer rubber layer, after mixing, the outer rubber layer colloid is obtained, and the mixing conditions are the same as The inner rubber layer raw materials are the same; S2, vulcanization: mix the cor...

Embodiment 2

[0031] Embodiment 2: A modified epoxy phenolic high-temperature thermal recovery surface pipeline, the pipeline is composed of an outer coating, an outer rubber layer, a skeleton layer, an inner rubber layer and an inner coating, and the outer coating and the inner coating have the same composition. Its preparation process includes the following steps: S1, the first mixing: put the corresponding number of inner rubber layer raw materials into the mixing chamber of the internal mixer for mixing, after mixing, the inner rubber layer colloid is obtained, and the mixing temperature is 80°C. The rotor speed of the internal mixer is 60r / min, the mixing time is 12min, and the top bolt pressure of the internal mixer is 0.7mpa; repeat the above steps to mix the raw materials of the outer rubber layer, after mixing, the outer rubber layer colloid is obtained, and the mixing conditions are the same as The inner rubber layer raw materials are the same; S2, vulcanization: mix the correspond...

Embodiment 3

[0033] Embodiment 3: A modified epoxy phenolic high-temperature thermal recovery surface pipeline, the pipeline is composed of an outer coating, an outer rubber layer, a skeleton layer, an inner rubber layer and an inner coating, and the outer coating and the inner coating have the same composition. Its preparation process includes the following steps: S1, the first mixing: Put the corresponding number of inner rubber layer raw materials into the internal mixing chamber of the internal mixer for mixing, after mixing, the inner rubber layer colloid is obtained, and the mixing temperature is 90°C. The rotor speed of the internal mixer is 70r / min, the mixing time is 15min, and the top bolt pressure of the internal mixer is 0.8mpa; repeat the above steps to mix the raw materials of the outer rubber layer, after mixing, the outer rubber layer colloid is obtained, and the mixing conditions are the same as The inner rubber layer raw materials are the same; S2, vulcanization: mix the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com