A double-wedge gate valve with external air-added auxiliary valve

A double-wedge, gate valve technology, used in sliding valves, valve devices, engine components, etc., can solve problems such as failure to meet valve requirements, and achieve the effect of ensuring neutrality, slowing down the service life, and ensuring tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

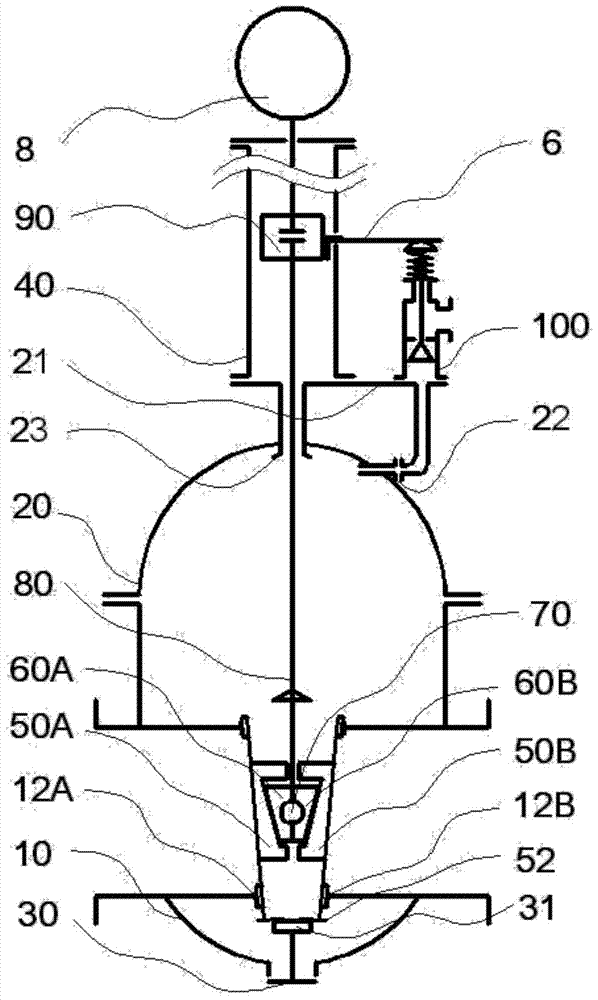

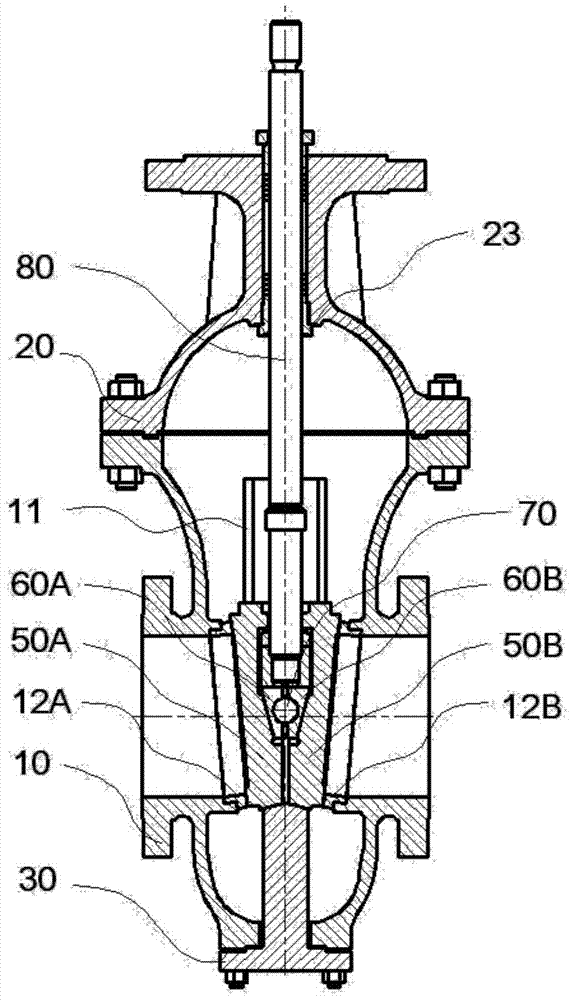

[0029] Such as figure 1 As shown, a double-wedge gate valve with an external gas auxiliary valve according to the present invention includes a valve body 10 with a valve seat hole and a flow channel.

[0030] The top of the valve body 10 is connected to the valve cover 20 through a flange. An external gas sub-valve base 21 is provided above the valve cover 20 , and an external gas sub-valve 100 is connected to the external gas sub-valve base 21 . An upper sealing seat 23 and a bracket 40 are also arranged above the valve cover 20 , the bracket 40 is equipped with a driving device 8 , and the other end of the above-mentioned valve rod 80 passes through the valve cover 20 and is connected with the driving device 8 through a coupling device 90 .

[0031] The lower part of the valve body 10 is connected to the bottom cover 30 through a flange. The bottom cover 30 has a column head 31 .

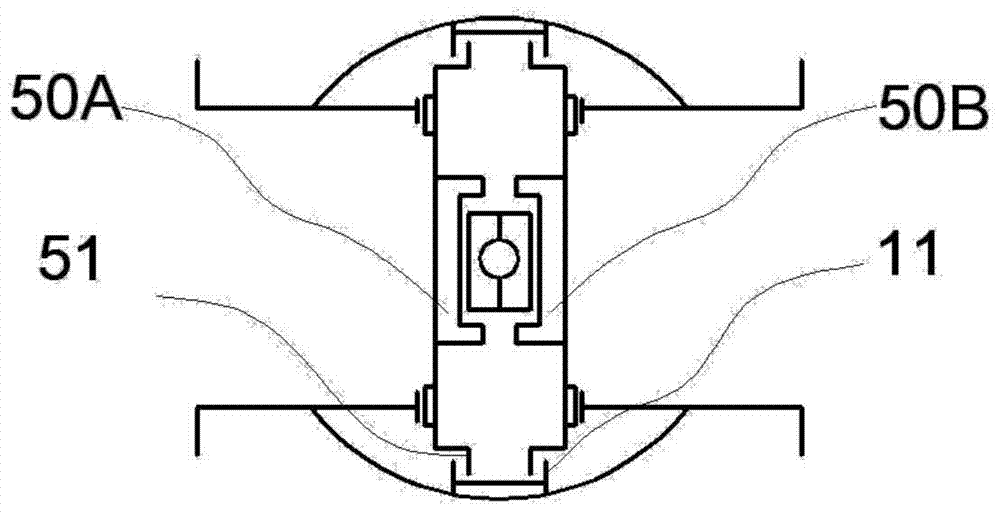

[0032] Such as figure 2 As shown, valve seat one 12A and valve seat two 12B are arranged ...

Embodiment 2

[0044] Such as figure 1 As shown, a double-wedge gate valve with an external gas auxiliary valve according to the present invention includes a valve body 10 with a valve seat hole and a flow channel.

[0045] The top of the valve body 10 is connected to the valve cover 20 through a flange. An external gas sub-valve base 21 is provided above the valve cover 20 , and an external gas sub-valve 100 is connected to the external gas sub-valve base 21 . An upper sealing seat 23 and a bracket 40 are also arranged above the valve cover 20 , the bracket 40 is equipped with a driving device 8 , and the other end of the above-mentioned valve rod 80 passes through the valve cover 20 and is connected with the driving device 8 through a coupling device 90 .

[0046] The lower part of the valve body 10 is connected to the bottom cover 30 through a flange. The bottom cover 30 has a column head 31 .

[0047] Such as figure 2 As shown, valve seat one 12A and valve seat two 12B are arranged ...

Embodiment 3

[0059] Such as Figure 9 As shown, the double wedge gate valve is accompanied by two auxiliary valves 100 for adding air. The difference from Embodiments 1 and 2 is that the inlet of the newly added auxiliary air valve 100 is connected to the external air source, and the outlet is connected to the upstream or downstream pipeline of the valve. When the double wedge gate valve is closed, the auxiliary air valve 100 is also open, as in Figure 9 As shown by the middle arrow, at this time, the external air enters the pipeline through the external air auxiliary valve 100, which can realize the medium purging function. This function can effectively prevent the phenomenon that the medium may coke there if there is a dead angle at the inlet and outlet when the upstream and downstream of the valve are installed on site.

[0060] The invention is suitable for shutting off valves in olefin reactors, and can also be used in working conditions such as high temperature, alternating temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com