Tooth-shaped deburring machine for upper surface and lower surface of continuous casting stainless steel plate blank

A deburring machine and deburring technology, applied in the field of machinery and equipment, can solve the problem of consuming a lot of manpower and material resources, and achieve the effect of ensuring the strength and durability of the tool, good cutting effect, and preventing the blade from being stuck and cannot be ejected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

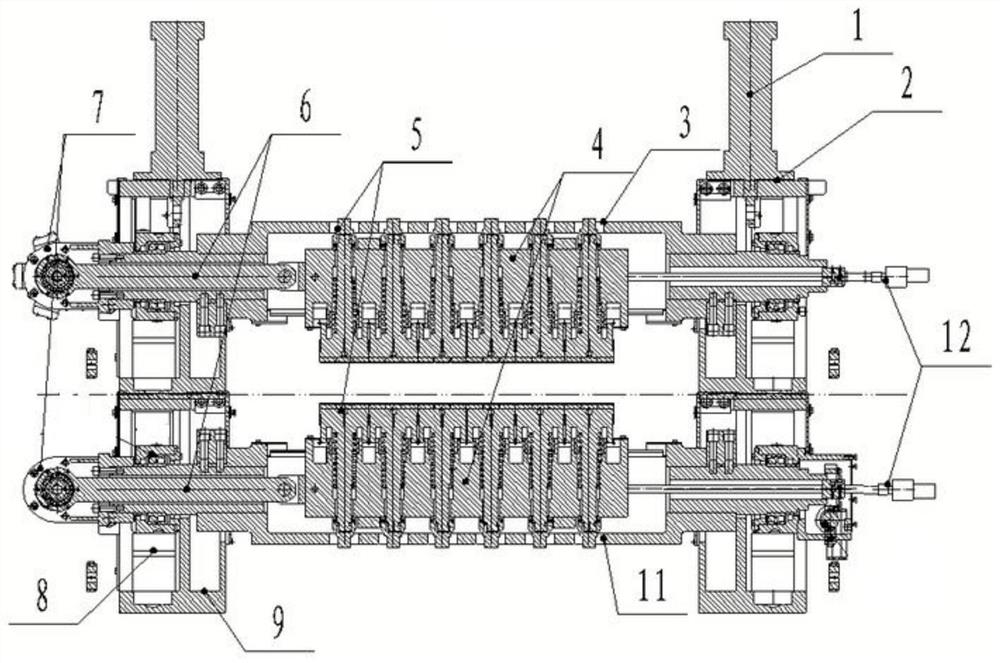

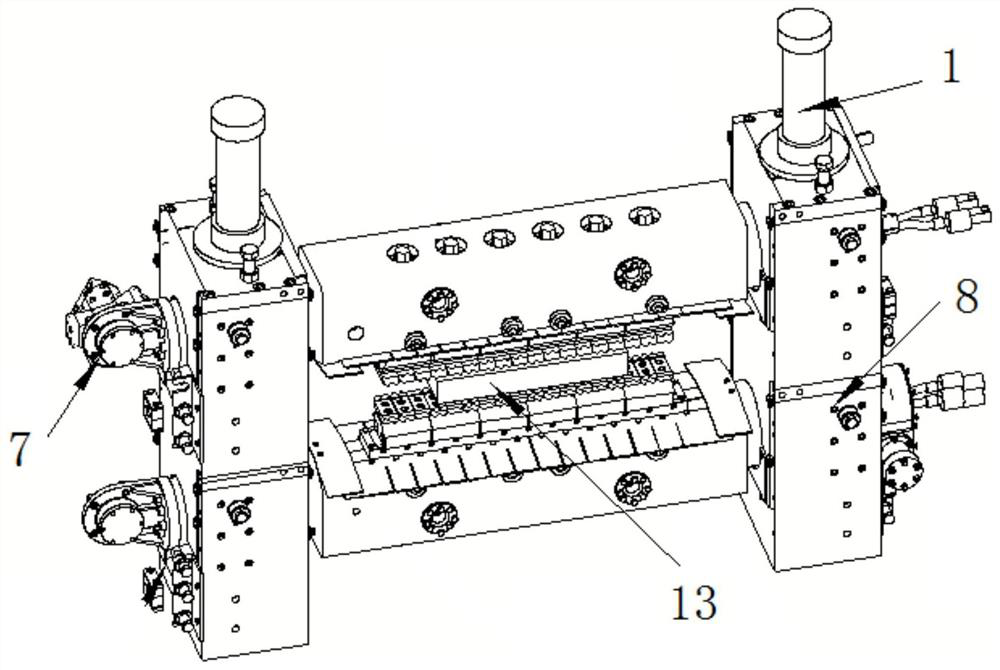

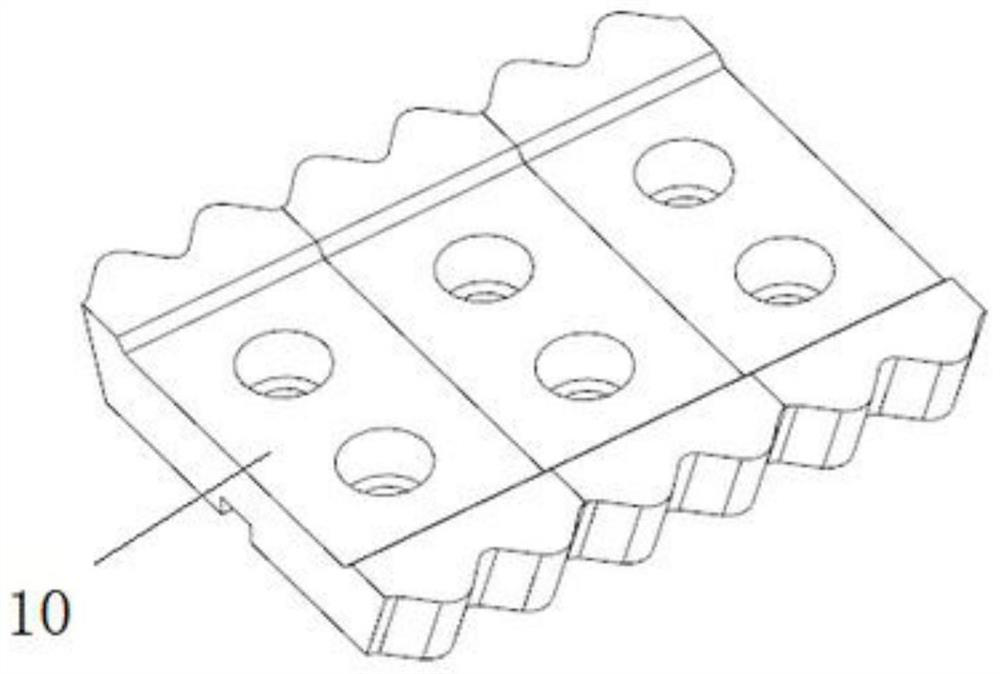

[0027] Such as Figure 1-8 As shown, a continuous casting stainless steel slab tooth profile deburring machine includes an upper deburring device and a lower deburring device, and the upper deburring device and the lower deburring device are combined and connected as one.

[0028] The upper deburring device includes the upper lifting cylinder 1, the upper support 2, the upper beam 3, the knife row and the knife row driving mechanism, and the lower deburring device includes the lower lifting cylinder 8, the lower support 9, the lower beam 11, the knife row and the knife row row drive mechanism; the upper support 2 includes a left seat and a right seat, and two upper lifting cylinders 1 are installed on the left seat and the right seat of the upper support 2 respectively, and the two ends of the upper beam 3 are connected with the two upper lifting cylinders 1 The piston rod is fixedly connected, the knife row is arranged on the upper beam 3, and the knife row driving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com