Coal low-temperature carbonization system and method

A low-temperature, dry distillation technology, applied in the field of dry distillation, to achieve the effect of shortening the residence time, reducing the secondary cracking reaction, and reducing the difficulty of type selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

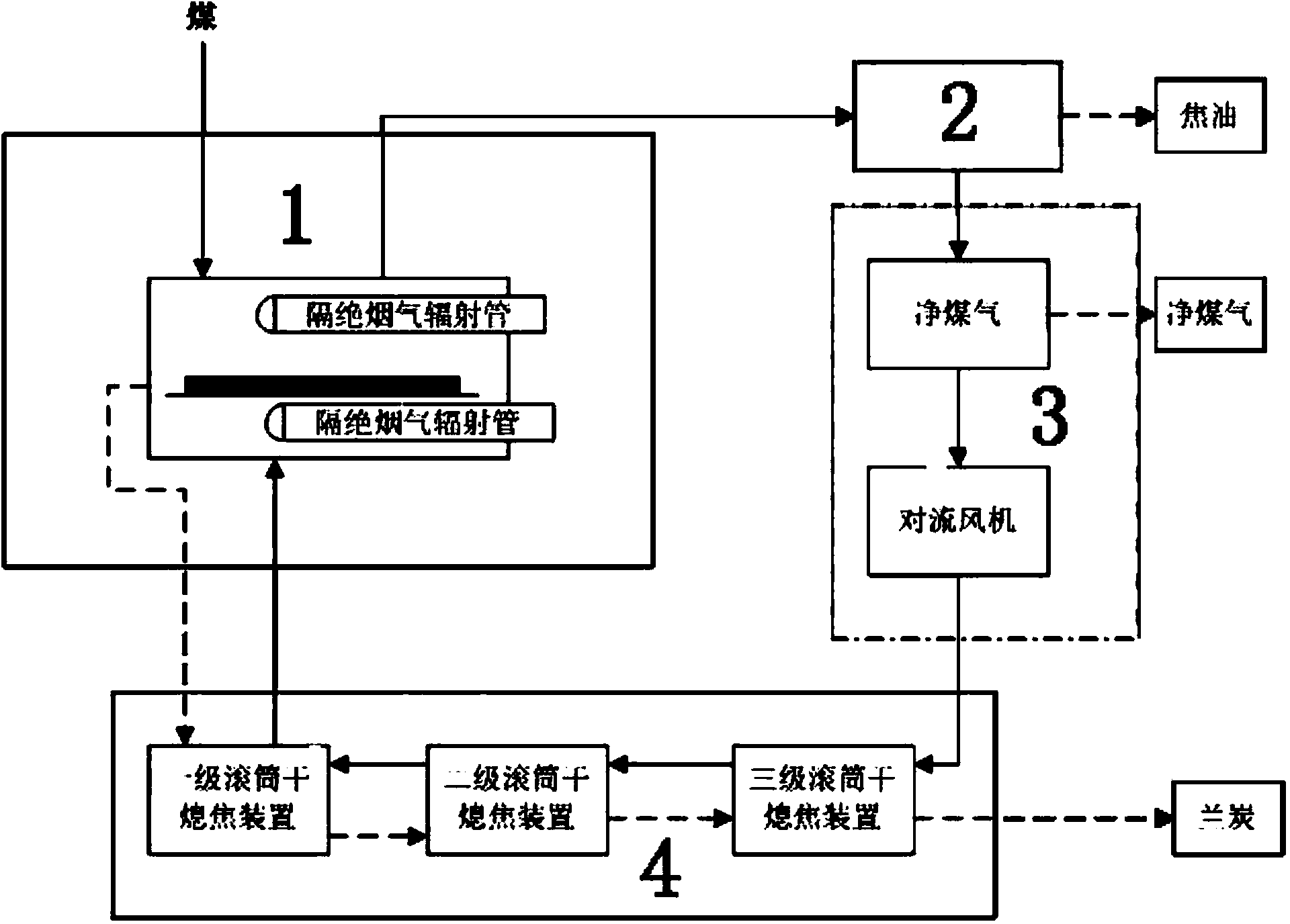

[0034] The rotary bed retort unit adopts the isolated flue gas radiant tube to heat the rotary bed retort furnace, with a processing scale of 1 million tons per year, taking the pyrolysis of long-flame coal as an example.

[0035] (1) The crushed raw coal enters the rotary bed carbonization unit. The carbonization conditions are final temperature of 650°C, cloth thickness of 180mm, reaction time of one revolution of 90min, semi-coke at 650°C from the side of the furnace, and oil gas at 650°C from the top of the furnace , 351,000 tons / year of high-temperature oil, gas and water are produced from the top of the furnace.

[0036] (2) The extracted high-temperature oil, gas, and water go through the gas washing and tar capture unit to purify the gas and collect the tar. The temperature of the gas and tar drops to 30°C. The circulating clean gas is introduced into the gas CDQ unit through the convection fan, as As the cooling medium of semi-coke, the collected tar and clean gas are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com