Gas Shower Device Having Gas Curtain And Apparatus For Depositing Film Using The Same

A thin film deposition device and spraying device technology, which is applied in the fields of electrical components, gaseous chemical plating, semiconductor/solid-state device manufacturing, etc., can solve the problems of low reaction gas concentration, shortened reaction zone stagnation time, and reduced reaction gas usage rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

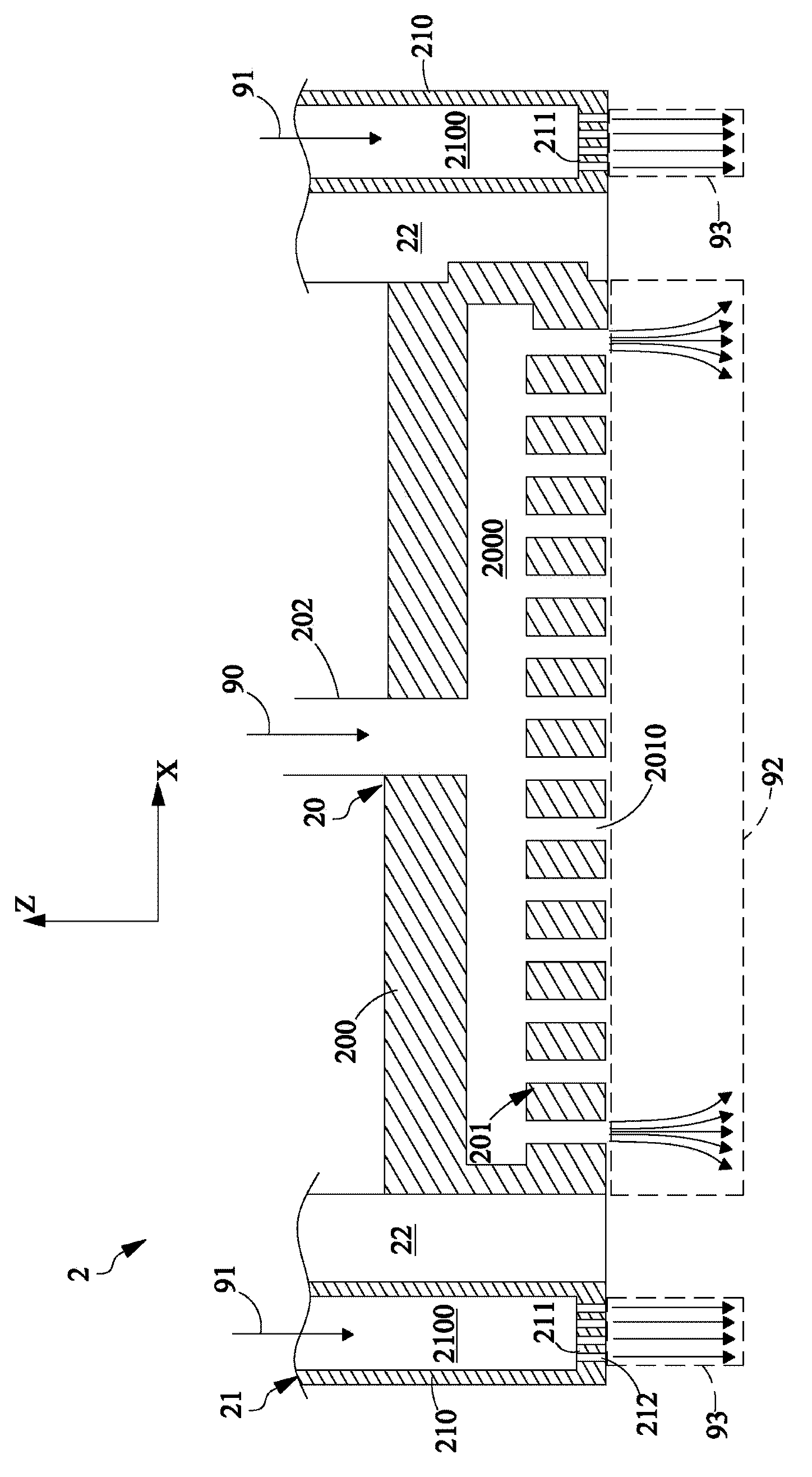

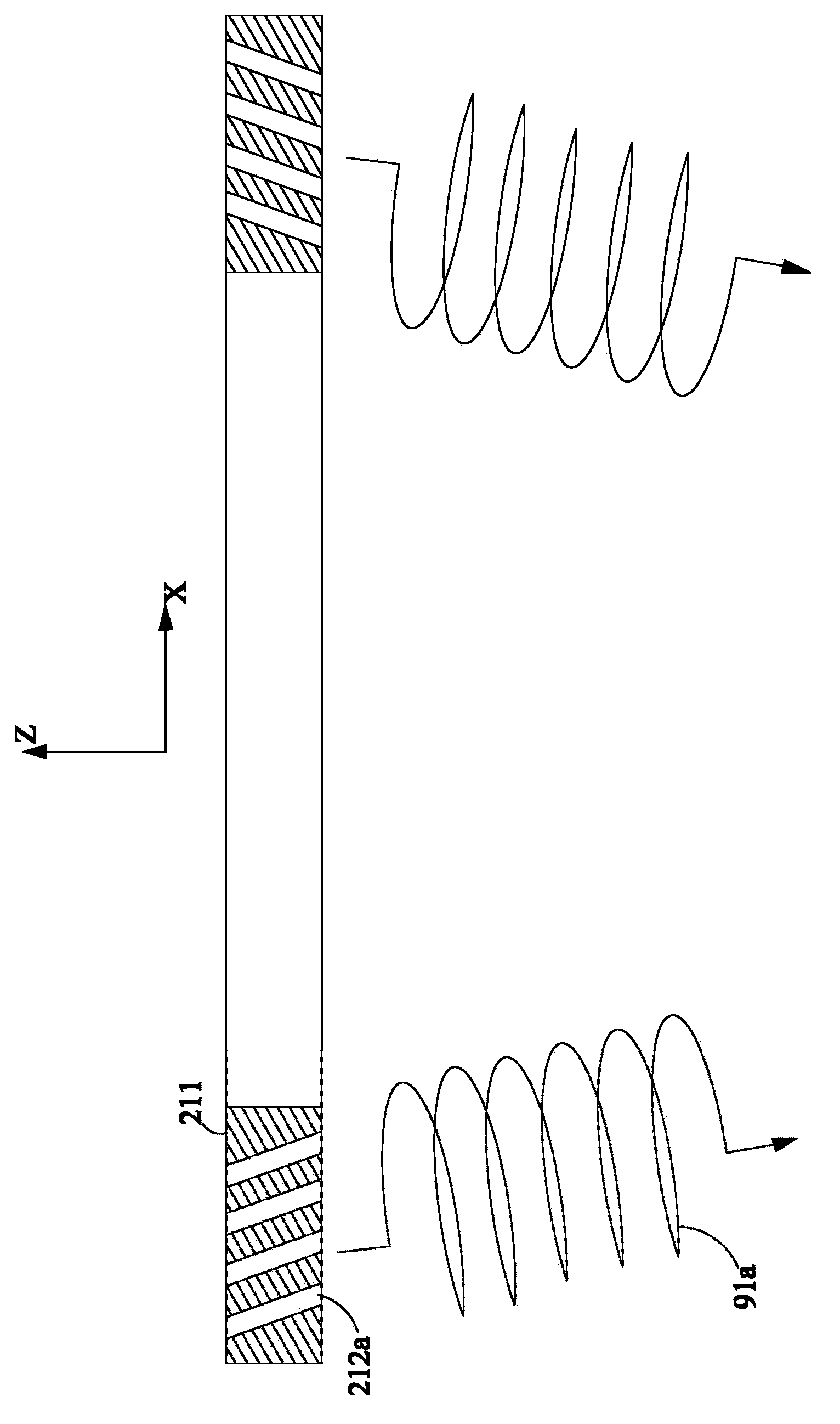

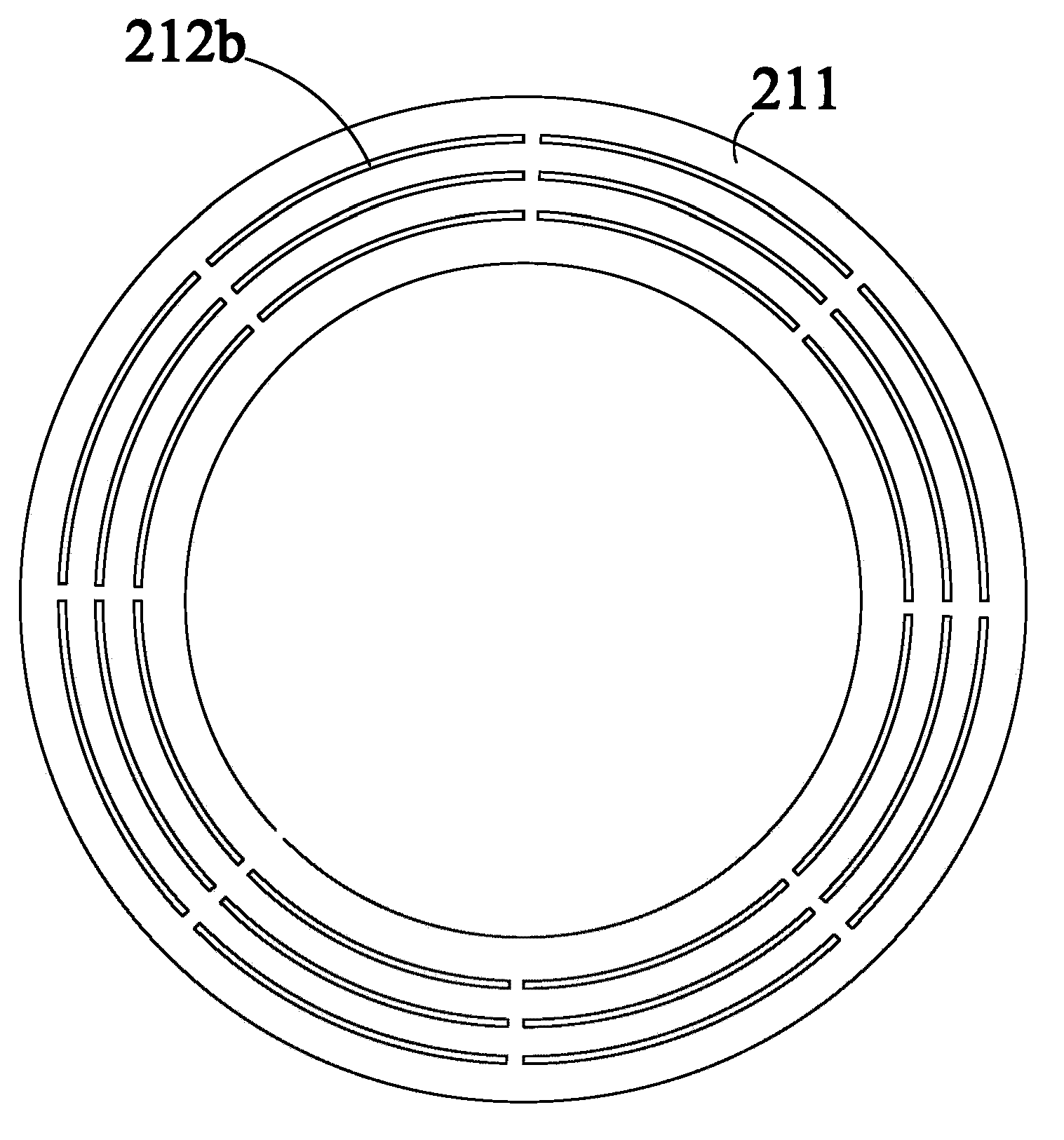

[0047] see figure 1 As shown, this figure is a schematic cross-sectional view of an embodiment of a gas spraying device capable of generating an air curtain according to the present invention. The gas spraying device 2 includes a first spraying unit 20 and a second spraying unit 21 . The first spraying unit 20 is used for receiving and spraying a reactive gas 90 to form a process gas zone 92 . In this embodiment, the first spraying unit 20 includes a reaction gas supply chamber 200 and a reaction gas distribution plate 201 . The reaction gas supply chamber 200 has a space 2000 for receiving the reaction gas 90 entering through at least one pipeline 202 . The reactant gas distribution plate 201 has a plurality of throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com