Process and system for thermal treatment of granular solids

A granular and solid technology, applied in chemical instruments and methods, chemical/physical processes, inorganic chemistry, etc., can solve problems such as air dust, loss of valuable products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] in accordance with Figure 6 In the system equipped, 50,000 kg / h of aluminum hydrate (ie aluminum hydroxide) with a moisture content of 7% by weight water was fed into the system at ambient temperature. In a first preheating stage 304, the hydrate is brought to a temperature of 170°C. Next, it is heated to 370° C. in a second preheating stage 320 and then calcined at 1000° C. in reactor 332 . The following particle classification is obtained in the second preheating stage with particles having a size <45 μm, depending on the heating process from 170 °C to 370 °C for a given time:

[0099] Table 1:

[0100]

[0101] Test V1 shows conventional heating: compared to this, tests V2, V3 and V4 show that the particle fractionation can be substantially reduced by decidedly slower heating. Test V5 shows that even a first rapid heating with a first ramp and a subsequent stabilization by a second heating ramp, which is much slower, still produces the effect according to the ...

Embodiment 2

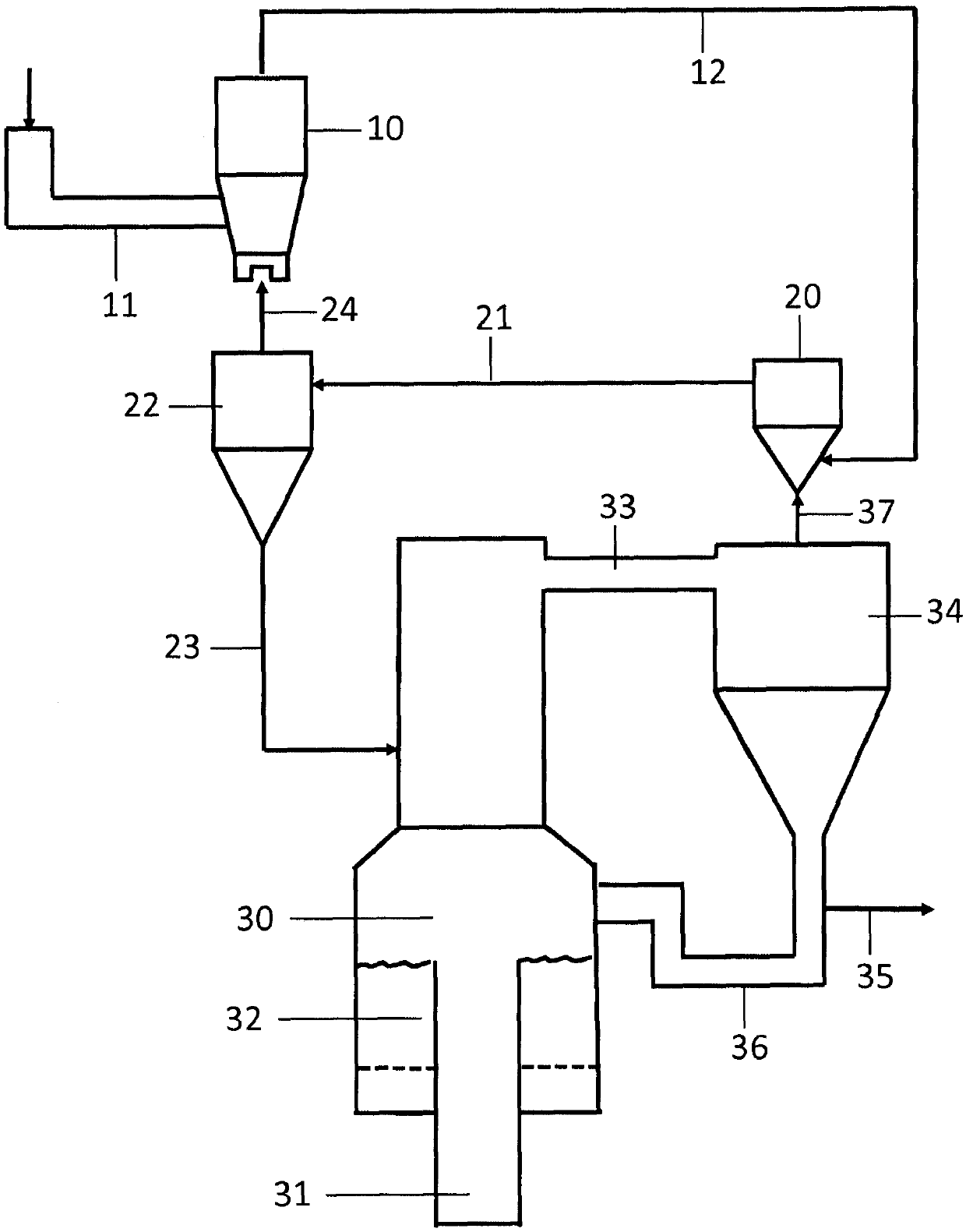

[0103] in accordance with figure 1 In the system equipped, 250,000 kg / h of aluminum hydrate (aluminum hydroxide) with a moisture content of 7% by weight water were fed into the system at ambient temperature. In a first preheating stage 10, the hydrate is brought to a temperature of 165°C. It is then heated to 330° C. in a second preheating stage 20 and then calcined at 1000° C. in a reactor 30 .

[0104] In the first run, the residence time of the particles in the second preheating phase 20 was ≦2-5 s. Due to the temperature rise of 165°C (=330°C-165°C), the heating rate is between 33 and 82.5K / s, and thus >15K / s. The result is about 5% by weight of particles with a diameter < 10 μm.

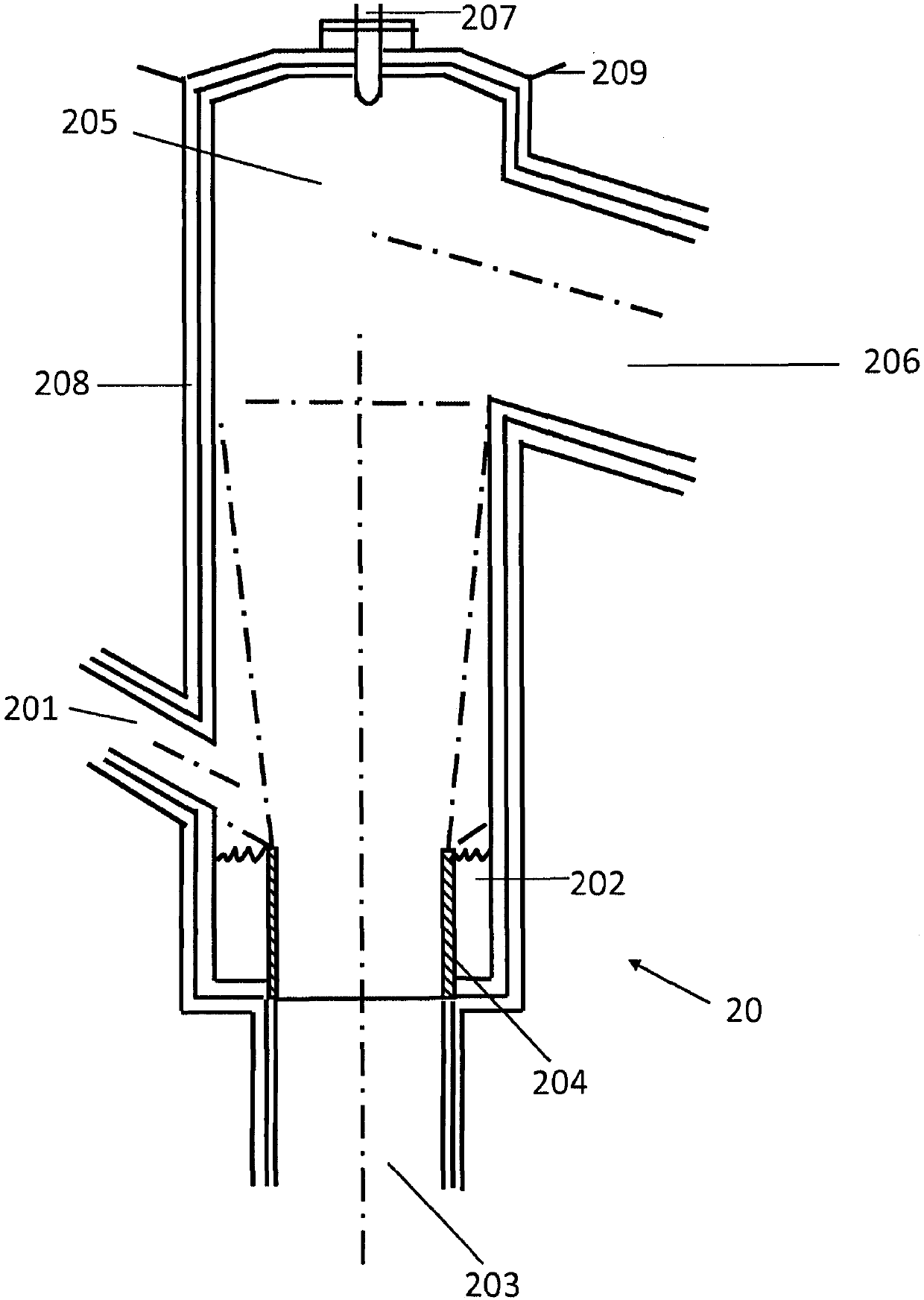

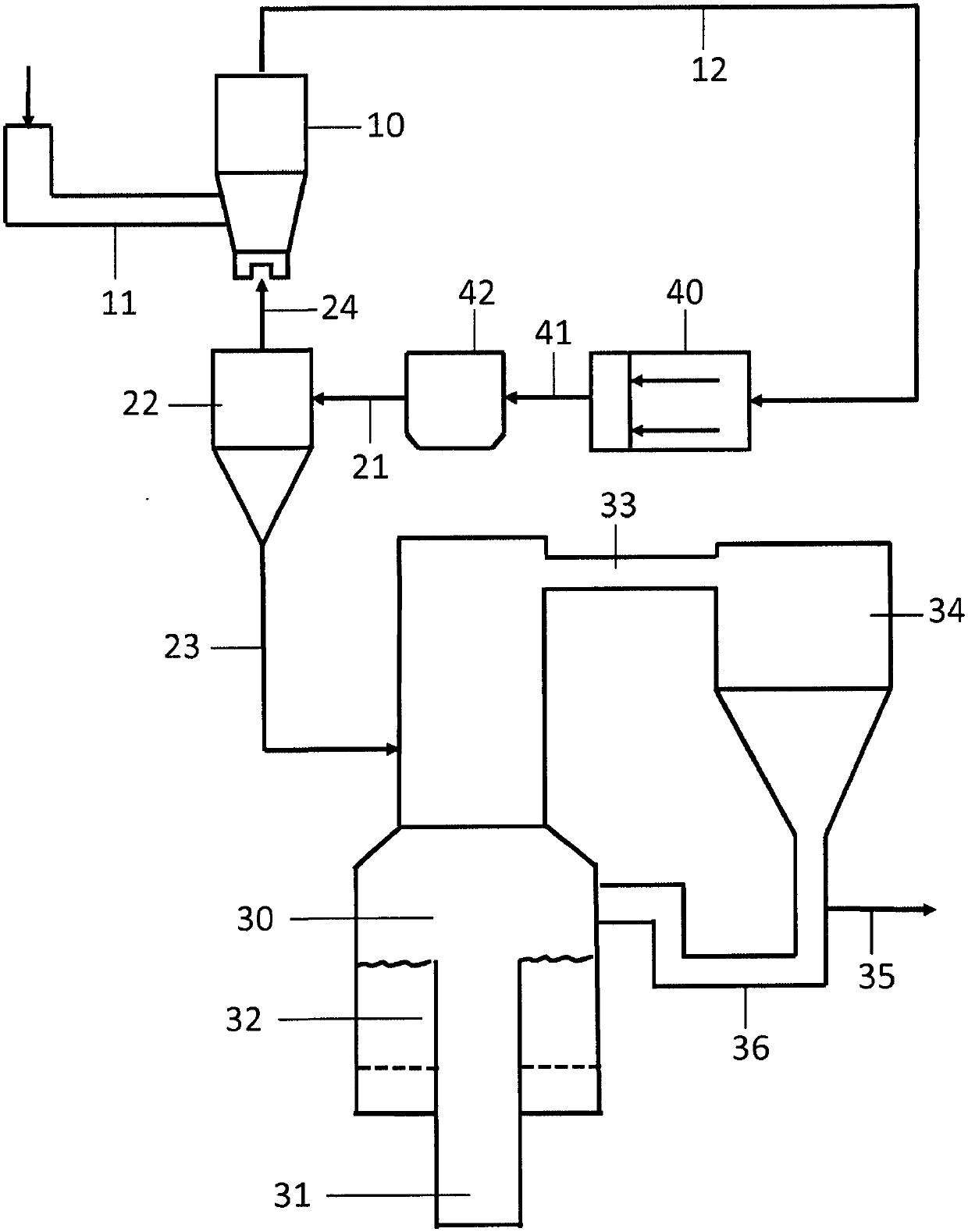

[0105] In contrast, using the image 3system. Again, 250,000 kg / h of aluminum hydrate with a moisture content of 7% by weight of water was fed into the system at ambient temperature. In a first preheating stage 10, the hydrate is brought to a temperature of 165°C. In the second preheating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com