Thin film forming apparatus

A technology of thin film and raw material gas, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of unbalanced pressure and low reactivity in the gas stagnation chamber 40, and achieve improved reactivity, The effect of saving raw materials and reducing the generation of growth-type foreign matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

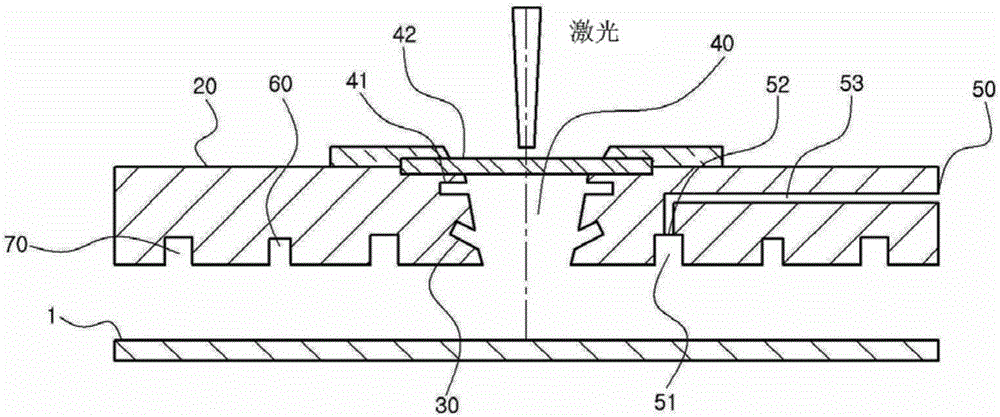

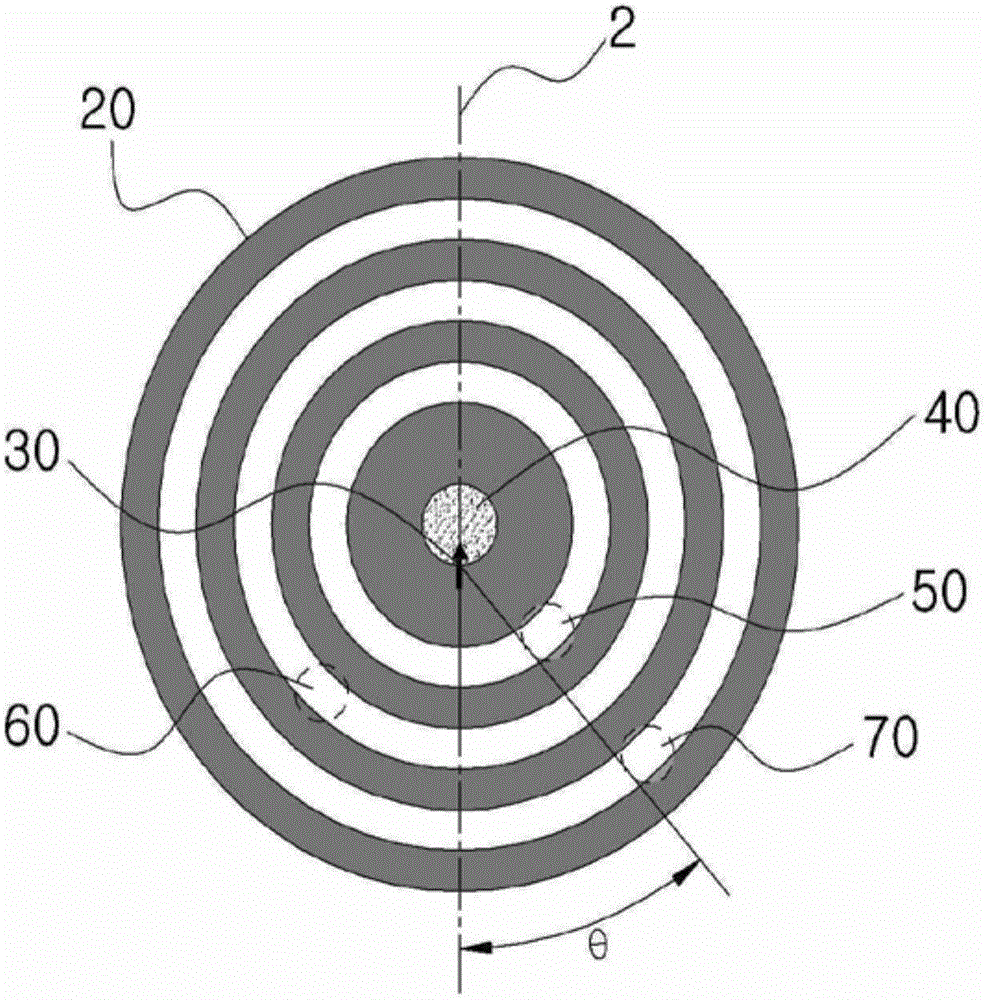

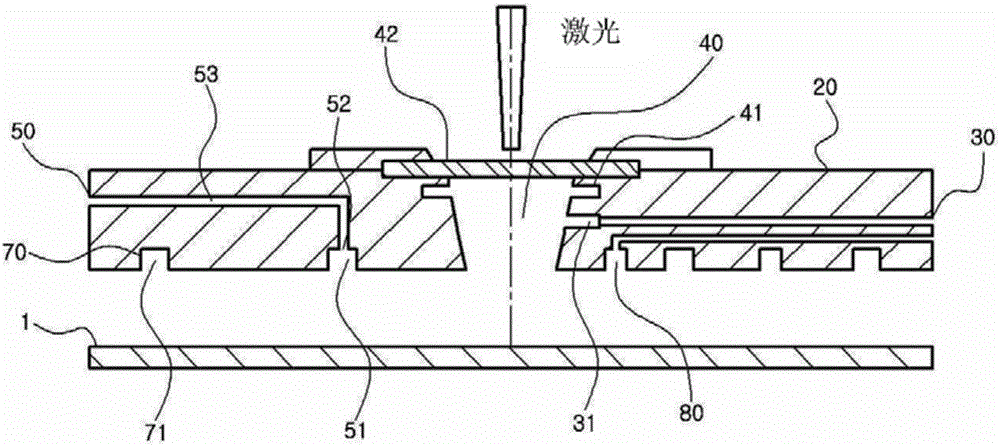

[0032] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. In this process, the thickness of a plurality of lines or the size of structural elements shown in the drawings may be exaggerated for the sake of clarity and convenience of description.

[0033] In addition, a plurality of terms described later are terms defined in consideration of functions in the present invention, and may differ according to the user's or operator's intention or custom. Therefore, the definitions of such multiple terms should be performed according to the entire contents of this specification.

[0034] Moreover, the following examples do not limit the scope of claims of the present invention, but are merely illustrative matters of the structural elements proposed in the scope of claims of the present invention, include the technical ideas in the full text of the description of the present invention and include Among the structural elements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com