Tire inner tube rubber composition

A rubber composition and inner tube technology, applied in the field of rubber, can solve the problems of not being able to adapt to high-speed, overloaded, long-distance use conditions, poor load-bearing performance, and large size, etc., to achieve improved load-bearing performance, low production costs, and excellent processing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

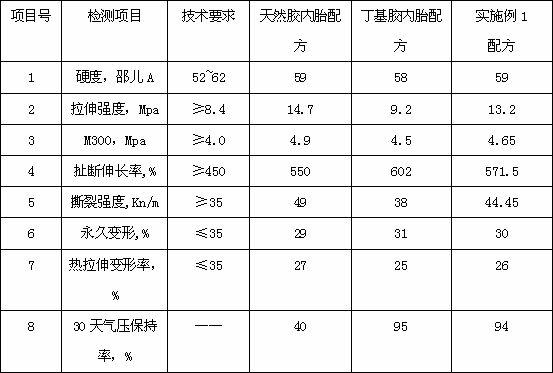

Examples

Embodiment Construction

[0008] Below in conjunction with embodiment the present invention will be further described:

[0009] The present invention comprises in weight parts: 35-45 parts of natural rubber, 50-70 parts of tire reclaimed rubber, 50-70 parts of brominated butyl reclaimed rubber, 10-20 parts of carbon black N660, 10-20 parts of Qiangwei powder, 1-2 parts of aromatic oil, 2-5 parts of stearic acid, 1-2 parts of anti-aging agent 4020, 1-2 parts of anti-aging agent RD, 1-2 parts of protective wax OK5194, 3-4 parts of rubber tackifying resin A-90 , 5 parts of zinc oxide, 0.3-0.5 parts of accelerator DM, 0.5-1.0 parts of accelerator CZ, 2-3 parts of sulfur.

[0010] Unit: kilogram

[0011] serial number components Example 1 Example 2 Example 3 Example 4 Example 5 1 natural rubber 35 38 40 42 45 2 tire reclaimed rubber 70 62 60 56 50 3 Bromobutyl reclaimed rubber 65 62 50 70 60 4 Carbon black N660 20 12 10 15 10 5 Strong p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com