Patents

Literature

36results about How to "Improve gas retention performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

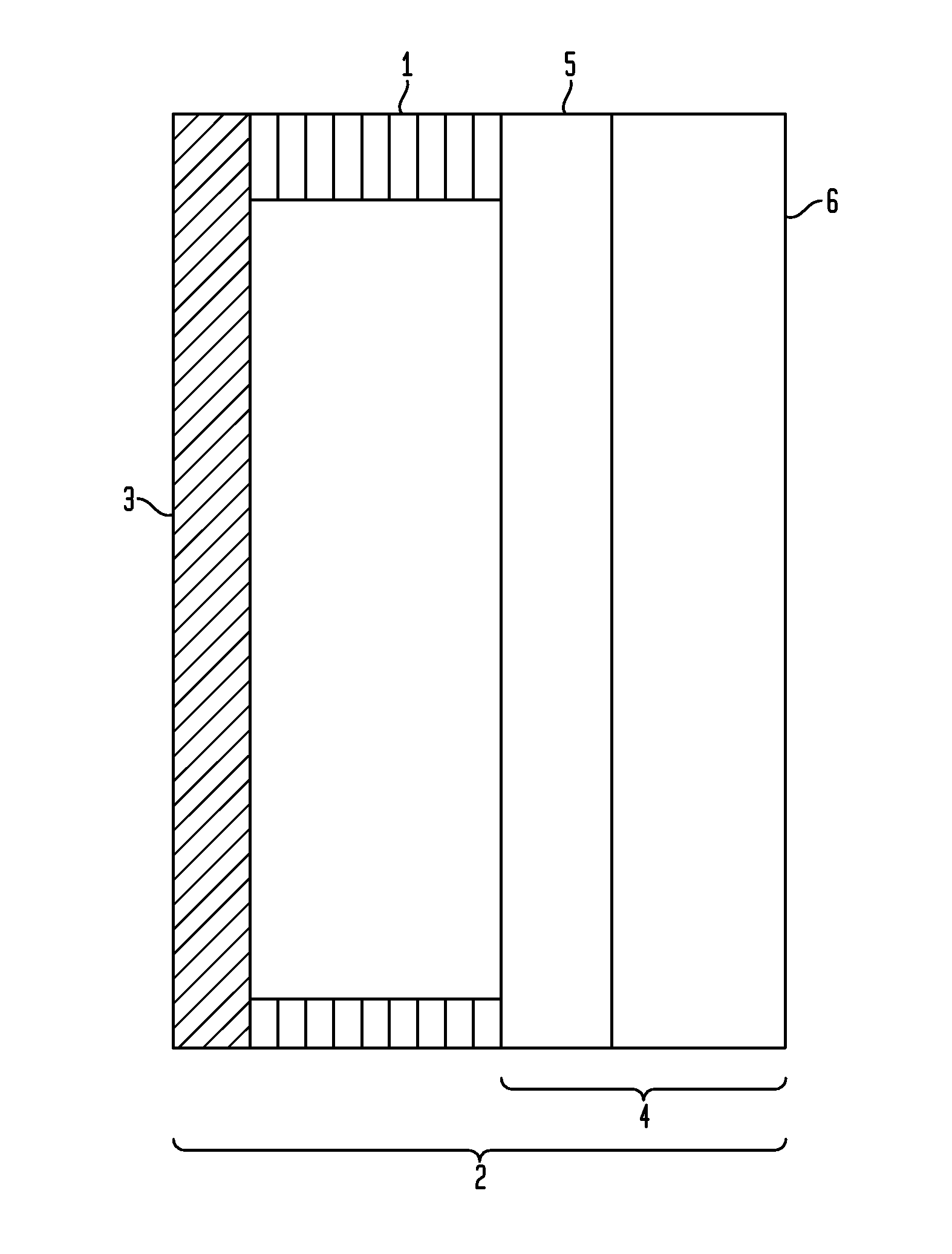

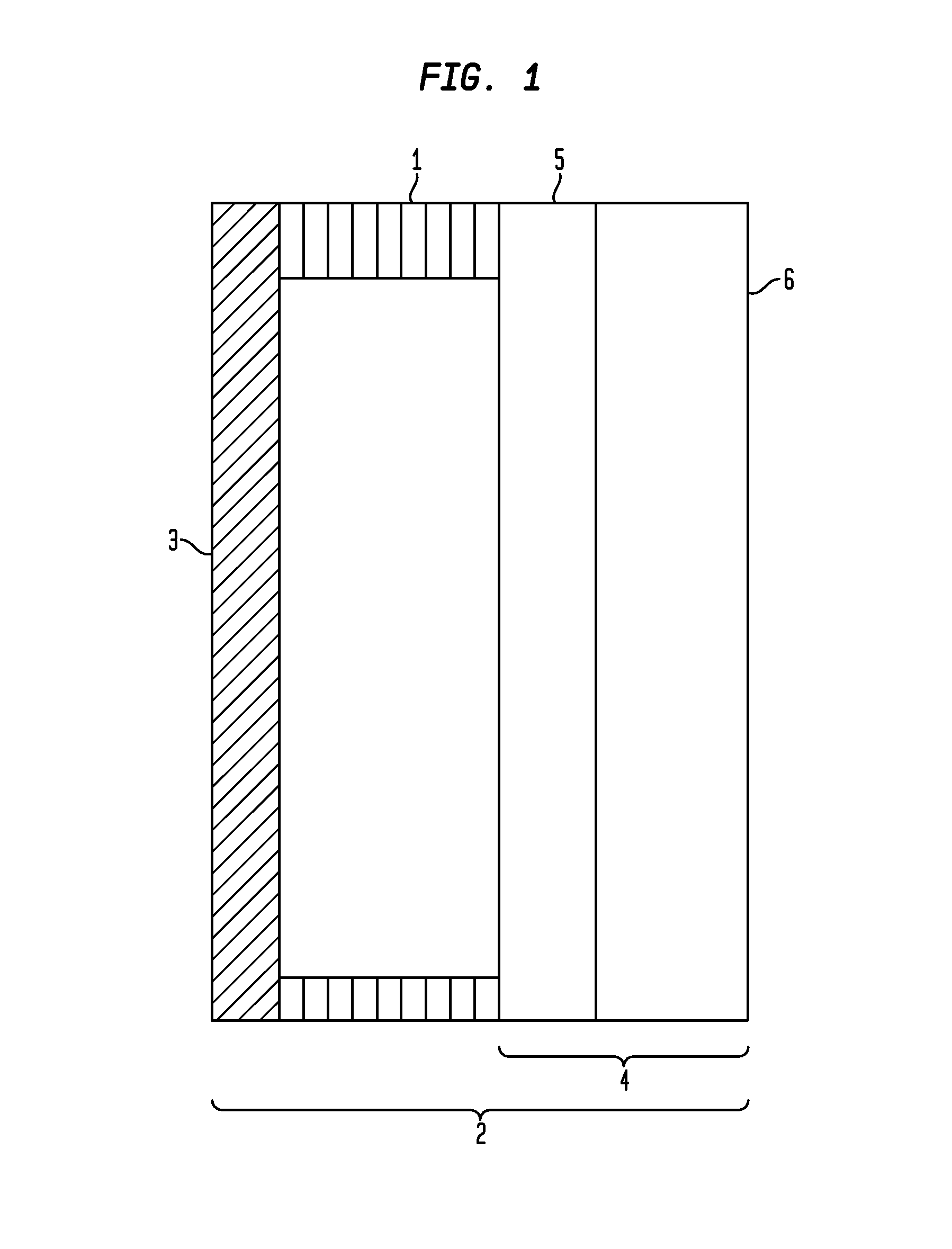

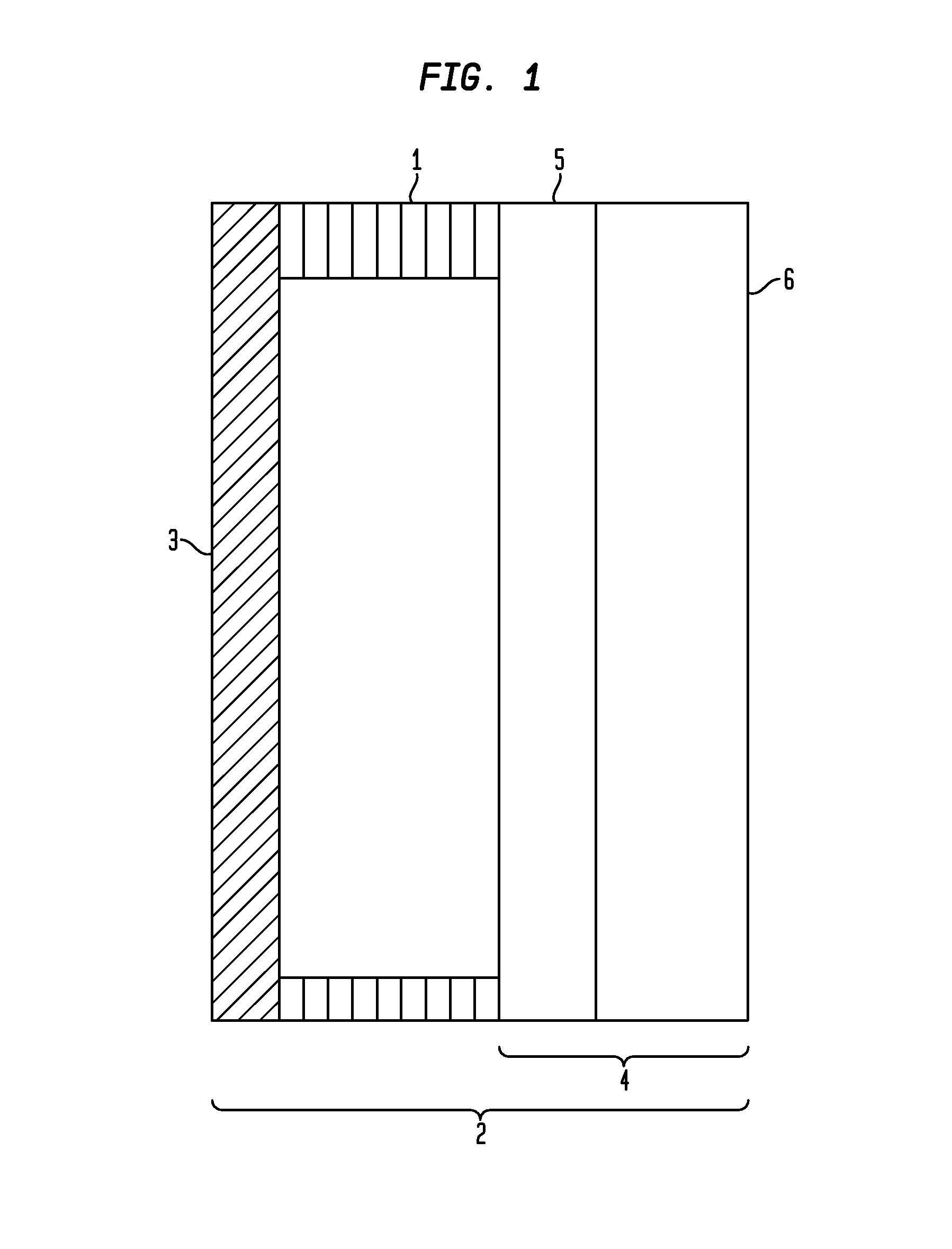

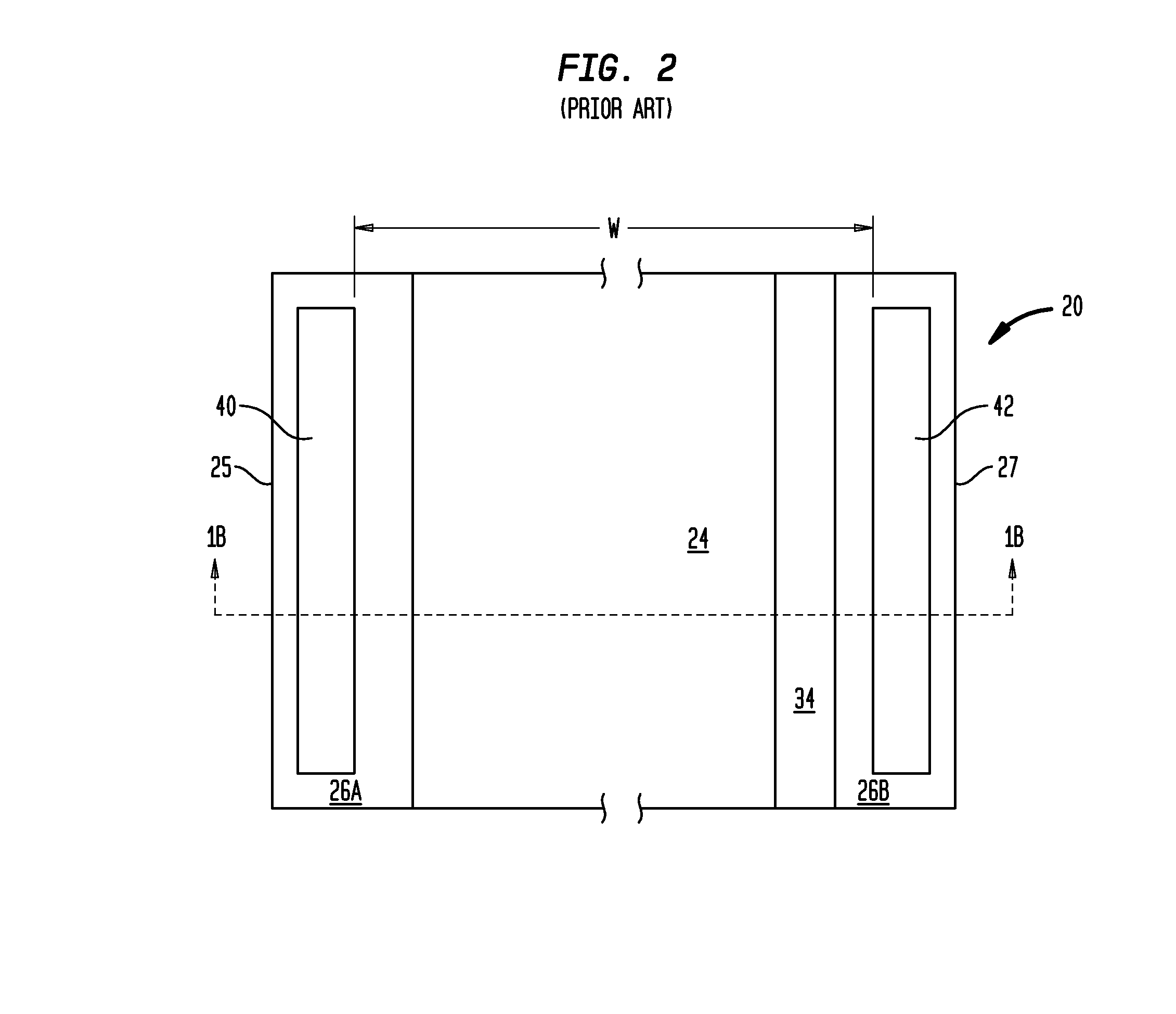

Color matched coating for bus bars

InactiveUS20140133005A1Mask porosityImprove gas retention performanceLight protection screensGlass/slag layered productsEngineeringPolymer

In one aspect, the present invention is a system comprising an electrochromic device having at least one bus bar and a color obscuration material wherein the at least one bus bar is coated with an over-coating material that is 1) substantially non-porous; and 2) substantially color-matched to one of said color obscuration material, a spacer, or a polymer seal.

Owner:SAGE ELECTROCHROMICS

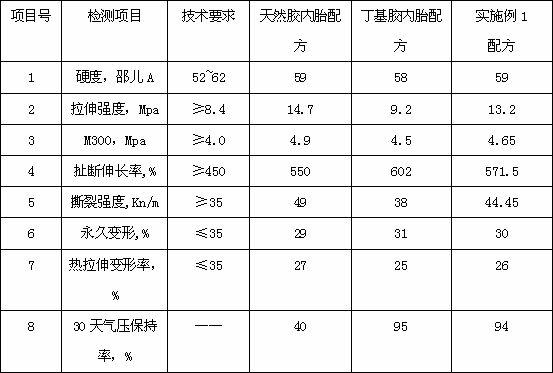

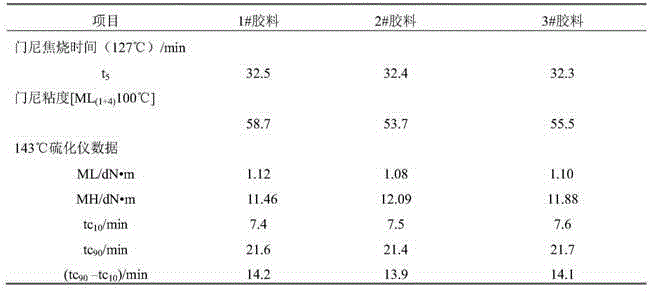

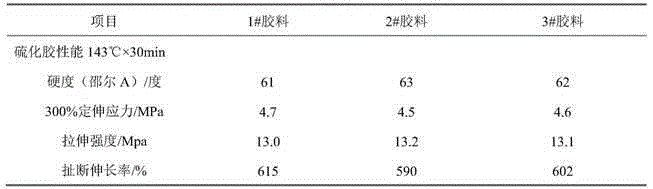

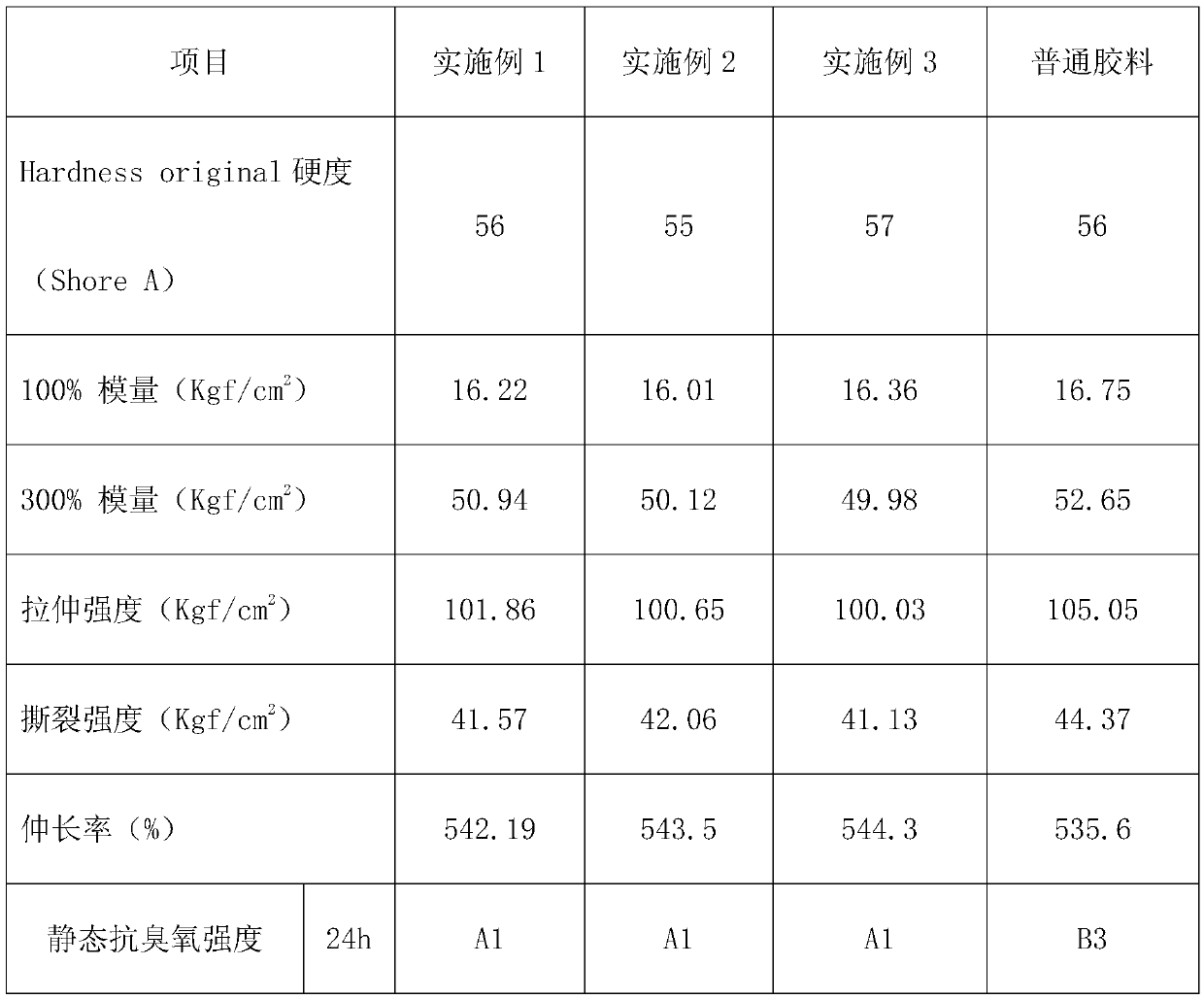

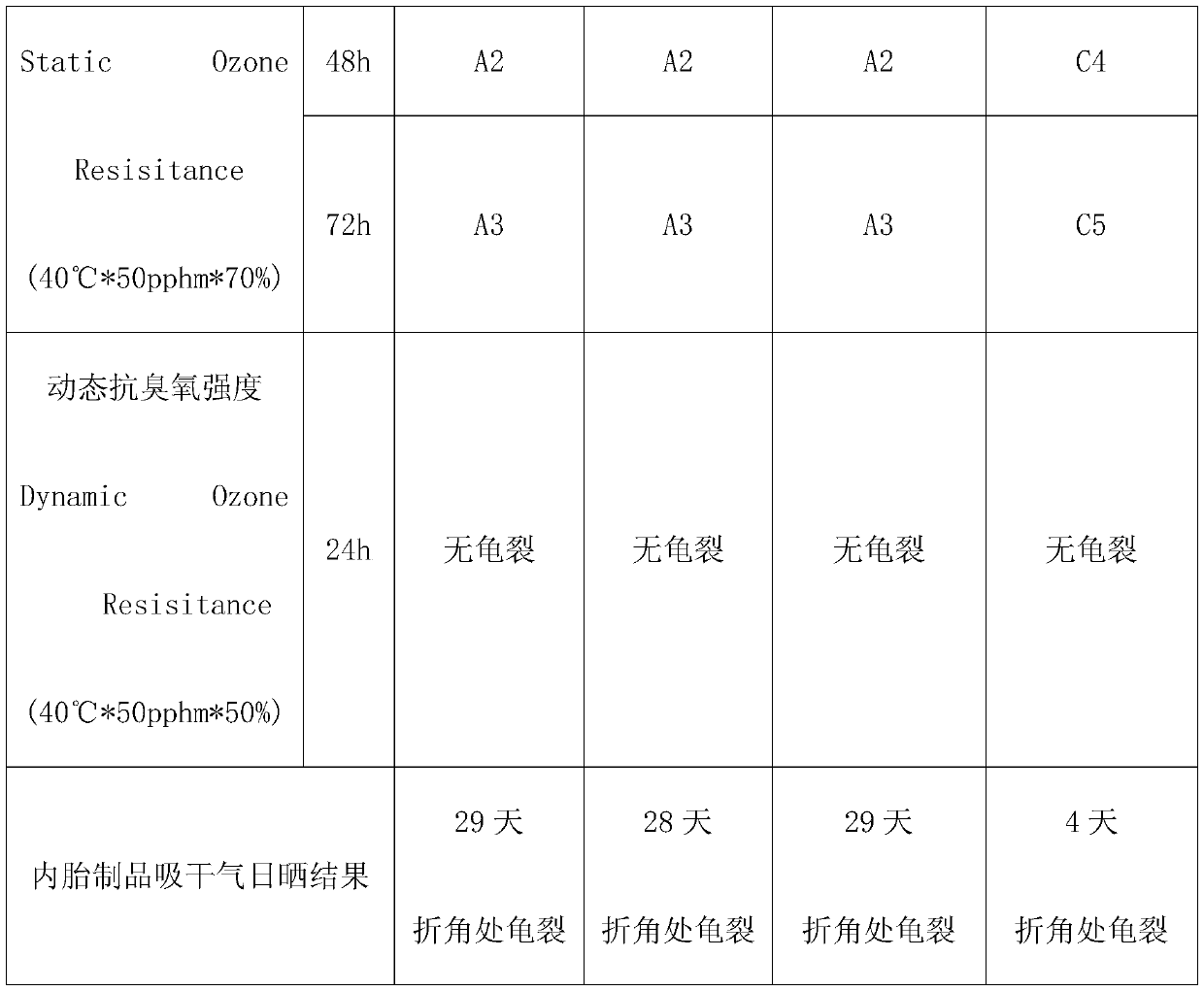

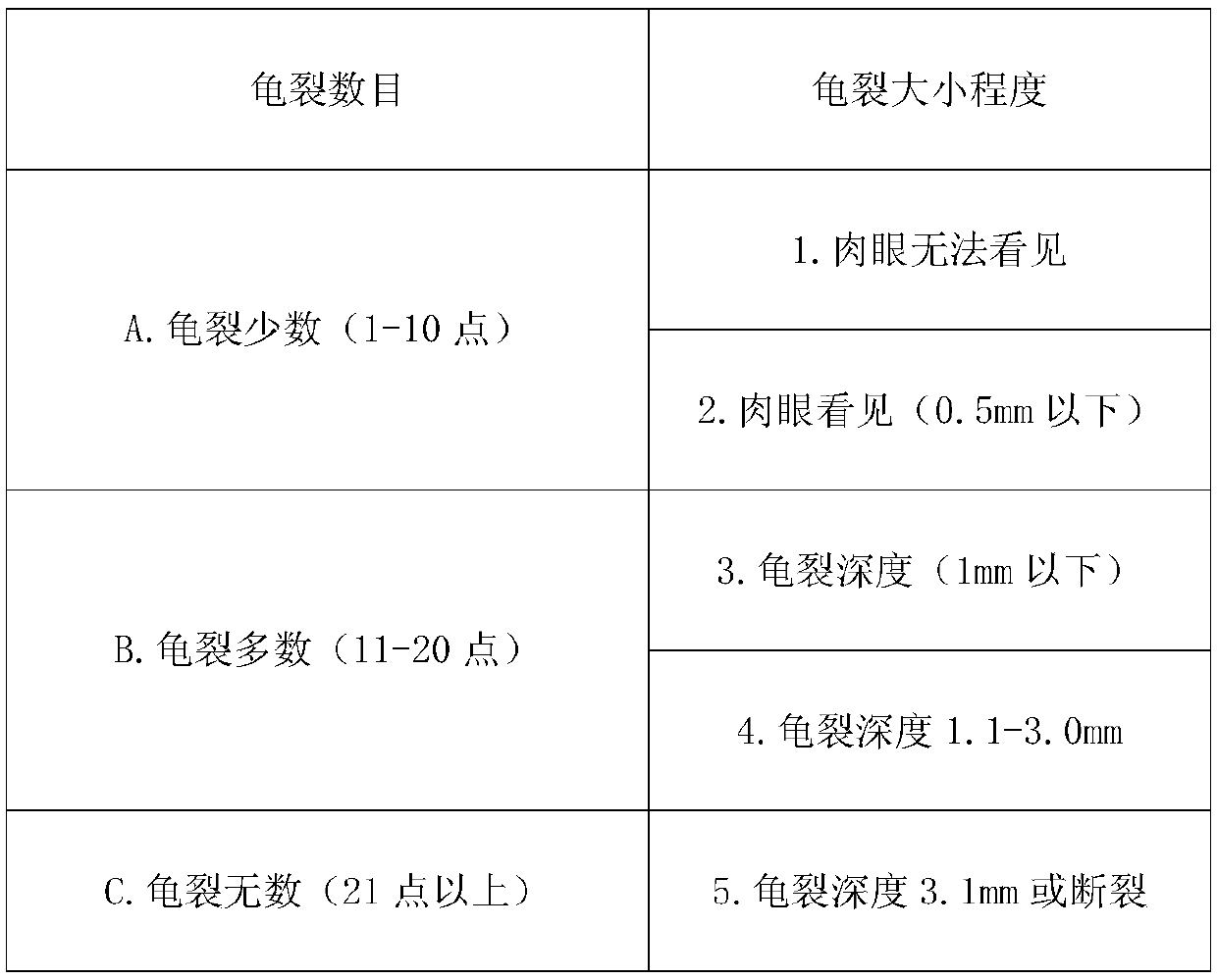

Tire inner tube rubber composition

The invention relates to the technical field of rubber, particularly a tire inner tube rubber composition which comprises the following components in parts by weight: 35-45 parts of natural rubber, 50-70 parts of outer tube regenerated rubber, 50-70 parts of brominated butyl regenerated rubber, 10-20 parts of carbon black N660, 10-20 parts of StronWiNTC, 1-2 parts of aromatic oil, 2-5 parts of stearic acid, 1-2 parts of anti-aging agent 4020, 1-2 parts of anti-aging agent RD, 1-2 parts of protective wax OK5194, 3-4 parts of rubber tackifying resin A-90, 5 parts of zinc oxide, 0.3-0.5 part of accelerator DM, 0.5-1.0 part of accelerator CZ and 2-3 parts of sulfur. The inner tube produced from the composition provided by the invention has the advantages of favorable gas retention performance, favorable aging resistance, high load carrying behavior, favorable processability and low cost.

Owner:TIUMSUN RUBBER TIRE WEIHAI

Color matched coating for bus bars

InactiveUS9158172B2Mask porosityImprove gas retention performanceLight protection screensBus-bar installationEngineeringElectrochromism

In one aspect, the present invention is a system comprising an electrochromic device having at least one bus bar and a color obscuration material wherein the at least one bus bar is coated with an over-coating material that is 1) substantially non-porous; and 2) substantially color-matched to one of said color obscuration material, a spacer, or a polymer seal.

Owner:SAGE ELECTROCHROMICS

Novel tire airtight liner promoter and preparation method and application thereof

ActiveCN104371266AReduce permeabilityImprove gas retention performanceSpecial tyresBuilding insulationsDriving safetyLubrication

Owner:SHANDONG YANGGU HUATAI CHEM

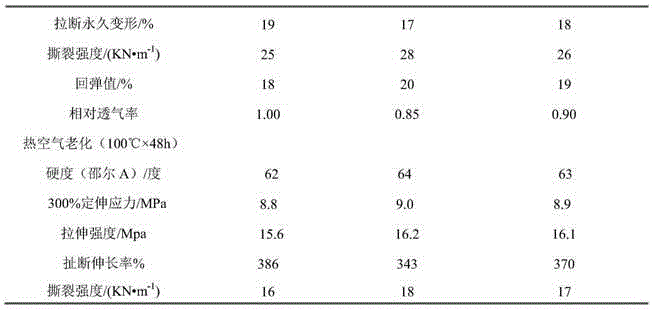

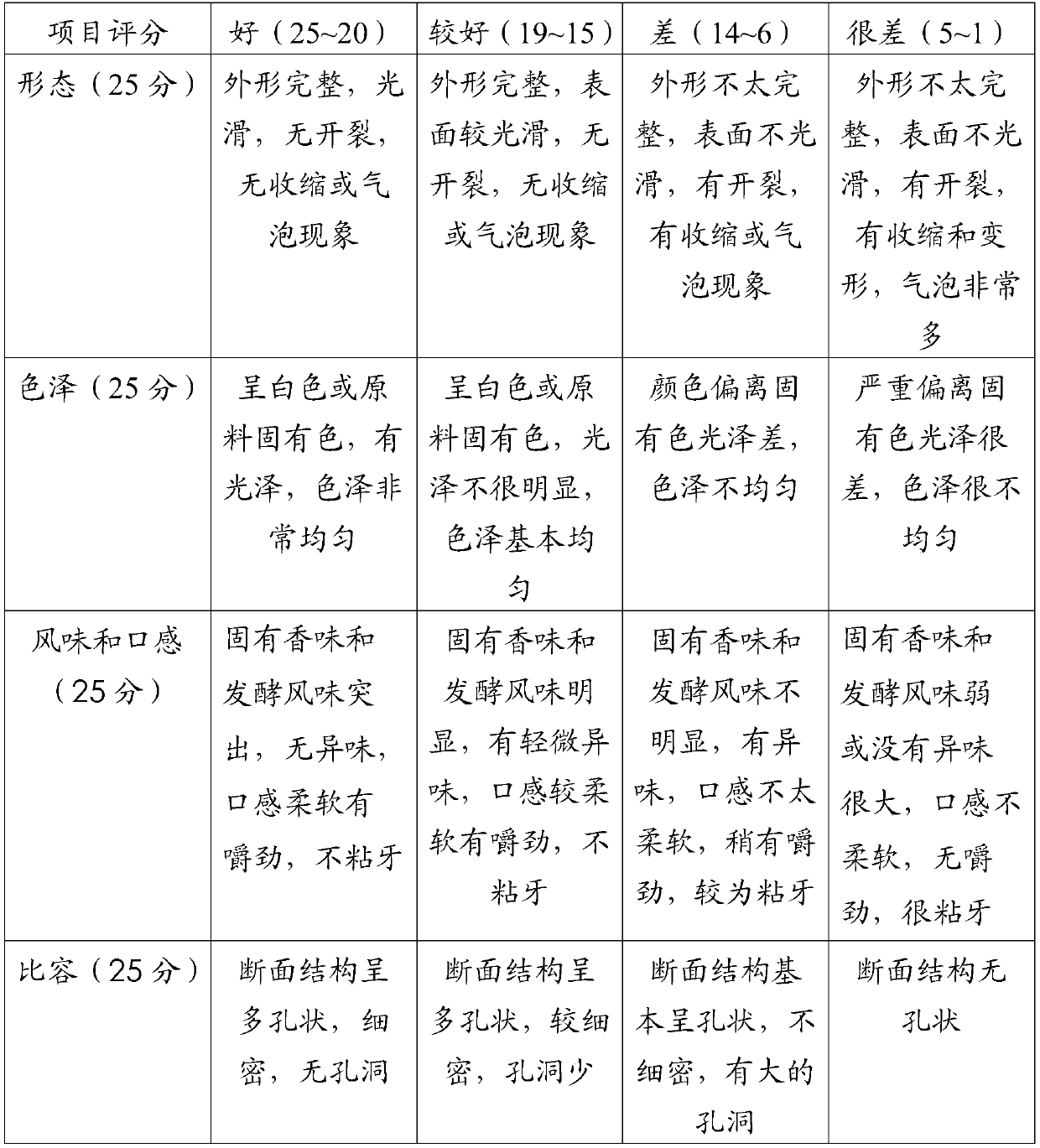

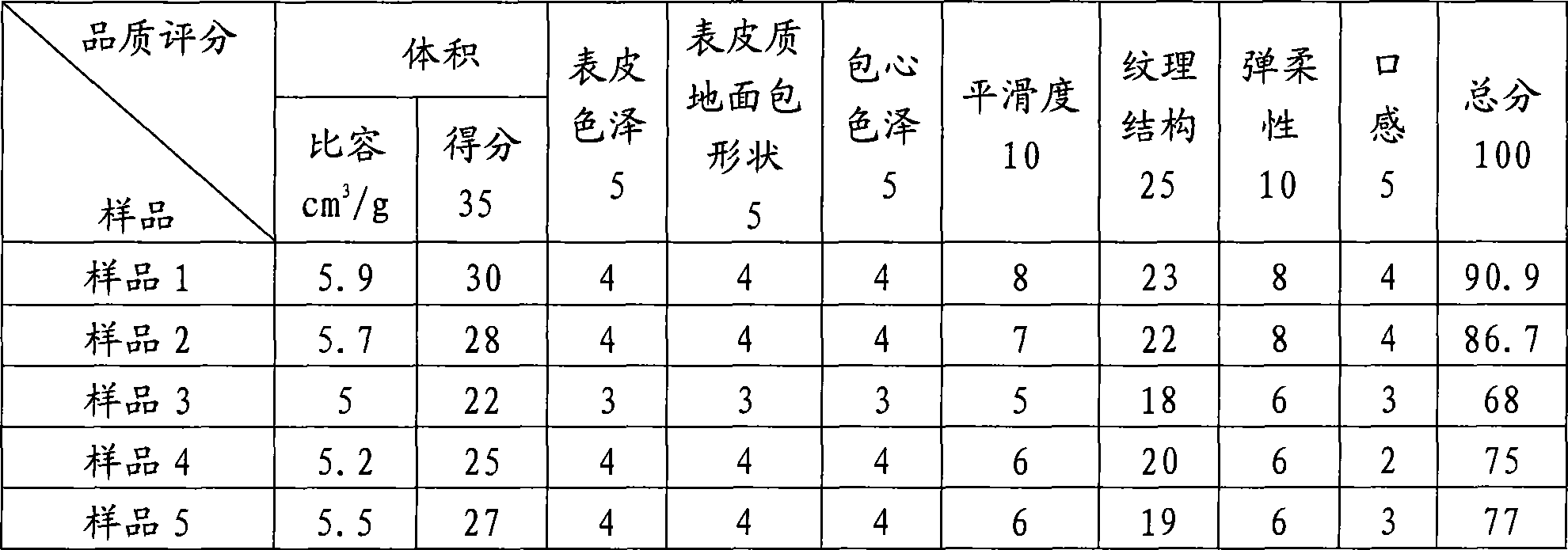

Gluten-free grain fermentation type flour product and preparation method thereof

The invention belongs to the technical field of food processing, and provides a gluten-free grain fermentation type flour product. The gluten-free grain fermentation type flour product is prepared from the following raw materials in parts by weight: 1.0 to 1.2 parts of gluten-free grain flour, 0.1 to 0.2 part of plant protein powder without gluten proteins, 0.01 to 0.03 part of yeast powder, 0.001to 0.05 part of TG enzyme, 0.01 to 0.05 part of lactobacillus plantarum powder, 0.01 to 0.03 part of salt, 0.01 to 0.02 part of bread improver and 0.6 to 0.8 part of water. According to the invention, after the raw materials are matched in the ratio, gas tightness of a gluten-free grain dough can be improved, and elasticity and a product volume of the gluten-free grain fermentation type steamed flour product in an initial stage of steaming are improved, so that the finally obtained gluten-free grain fermentation type steamed flour product is rich in nutrition, good in taste and excellent in flavor.

Owner:BOHAI UNIV

Four-prevention safety tire

InactiveCN107323179AImprove anti-static effectAvoid damageSpecial tyresPneumatic tyre reinforcementsCarbon nanotubeEngineering

Owner:SHANDONG FENGYUAN TIRE MFG

Brown rice bread and making method thereof

The invention belongs to the technical field of food processing, and in particular relates to a method for making brown rice bread by using glutathione as a modifier. The technical scheme is that: the brown rice bread is characterized by comprising the following components in part by mass: 1 to 1.2 parts of brown rice flour, 1 to 1.2 parts of water, 0.001 to 0.01 part of glutathione (food grade), 0.02 to 0.1 part of white sugar (or white granulated sugar) and 0.005 to 0.05 part of instant dry yeast. The basic components for making the brown rice bread are mainly brown rice flour, water, sugar, yeast and glutathione. The salt (sodium chloride) to be added in the process of making wheat bread is not contained, so the risk of causing the cardiovascular disease due to intake of high salt can be reduced.

Owner:马涛

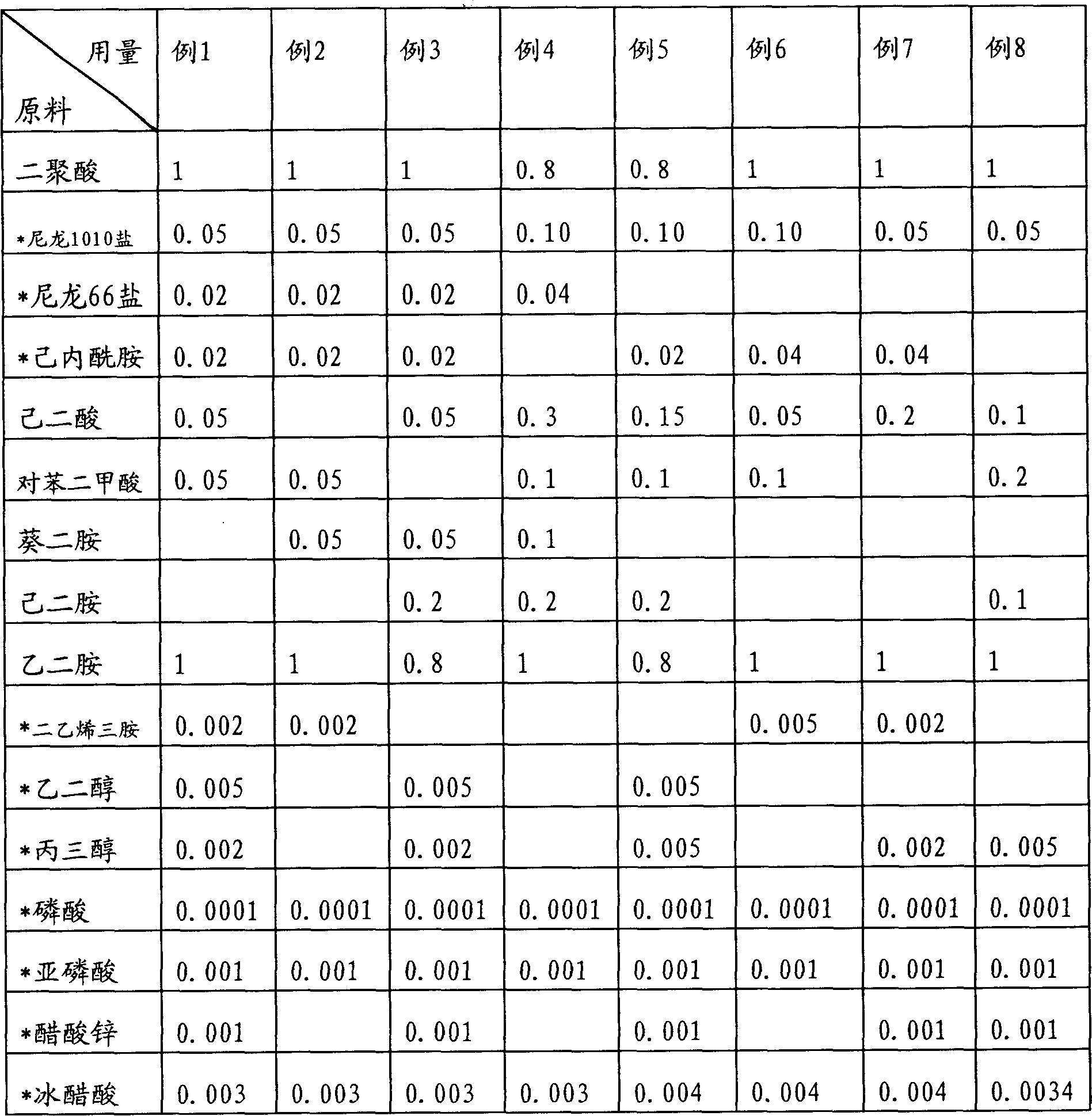

Polyamide-polyesteramide thermosol and its preparing process

A thermosol with polyamide or polyesteramide structure is prepared from dibasic acid and dibasic amine as primary raw material, adding modifier, chain-enlarging agent, catalyst, antioxidant, anti-ageing agent, optical stabilizer and terminating agent through polycondensating reaction. Its molecular wegiht is about in the range 3000-40000 dalton. Its advantages are wide temp. range for application (-30- +60 deg.C), high adhesion and thermal stability, and low cost.

Owner:SICHUAN TIANYI COMHEART TELECOM

Vitamin C microcapsule flour improver and preparation method thereof

ActiveCN101438721AImprove machinabilityImprove gas retention performanceDough treatmentPre-baking dough treatmentFlavorMonoglyceride

The invention relates to a vitamin C smicrocapsule flour improver and a preparation method thereof. The wall material of the flour improver is a mixed type wall material containing starch, stearic acid monoglyceride and hardened oil, and the bag core substance is vitamin C. The stearic acid monoglyceride and the hardened oil are mixed and then melted, then the starch and the vitamin C are added in the molten mass and evenly stirred to obtain the finished product by freezing, granulating and crushing. The smicrocapsule flour improver has the advantages of good stability, proper release rate, security, no foreign flavor and high utilization ratio of the vitamin C. In the method for preparing the vitamin C smicrocapsule flour improver, the realized cladding rate is up to 90 percent, no solvent is required to be used, the environmental pollution phenomenon does not exist, the process is simple and feasible and the cost is low.

Owner:中山市南方新元食品生物工程有限公司

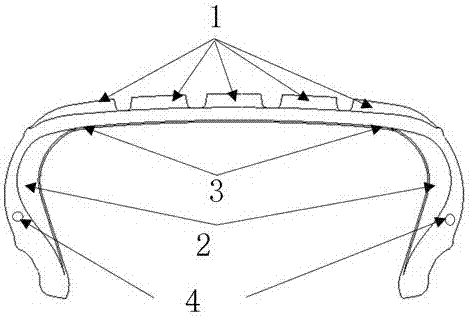

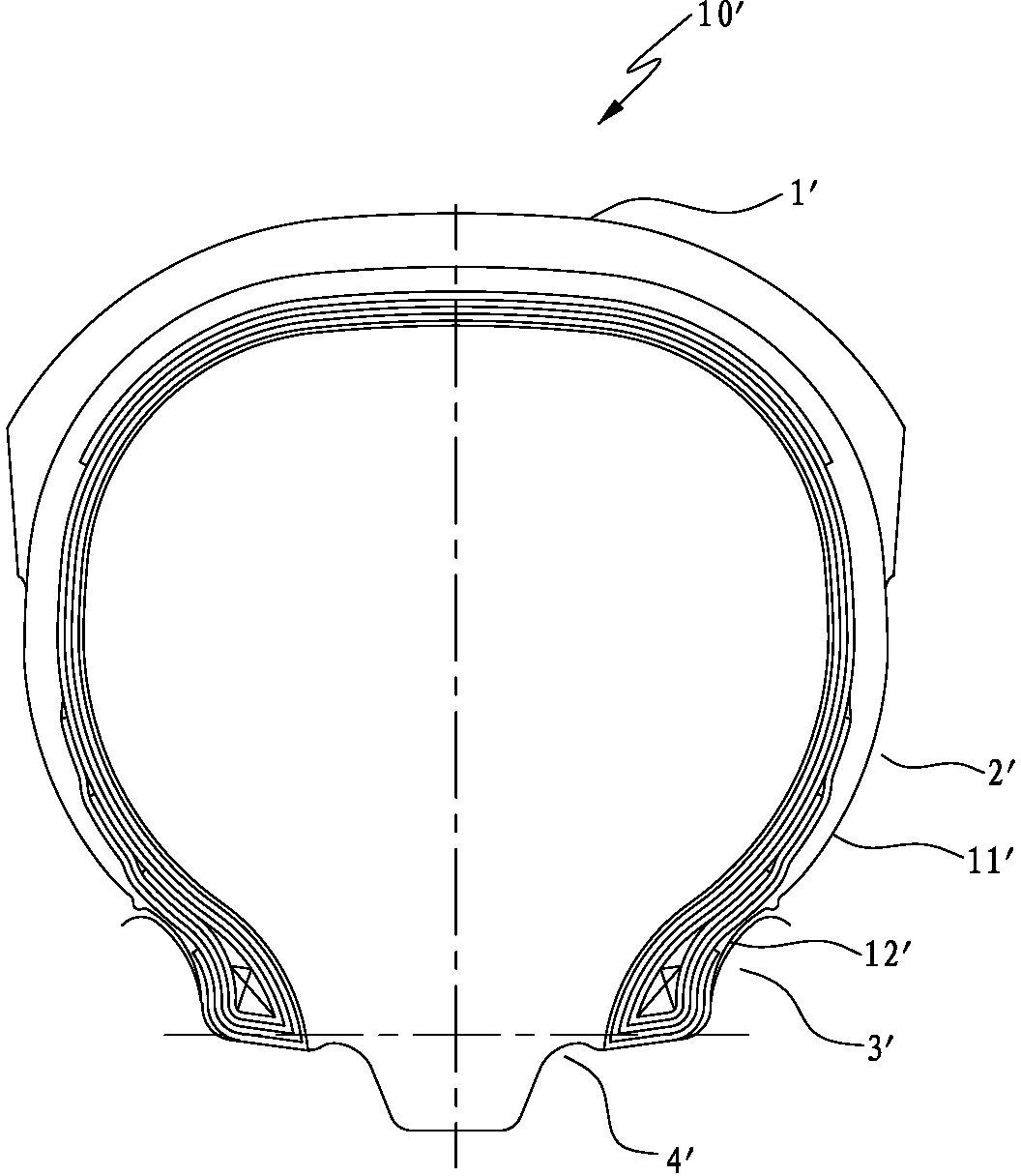

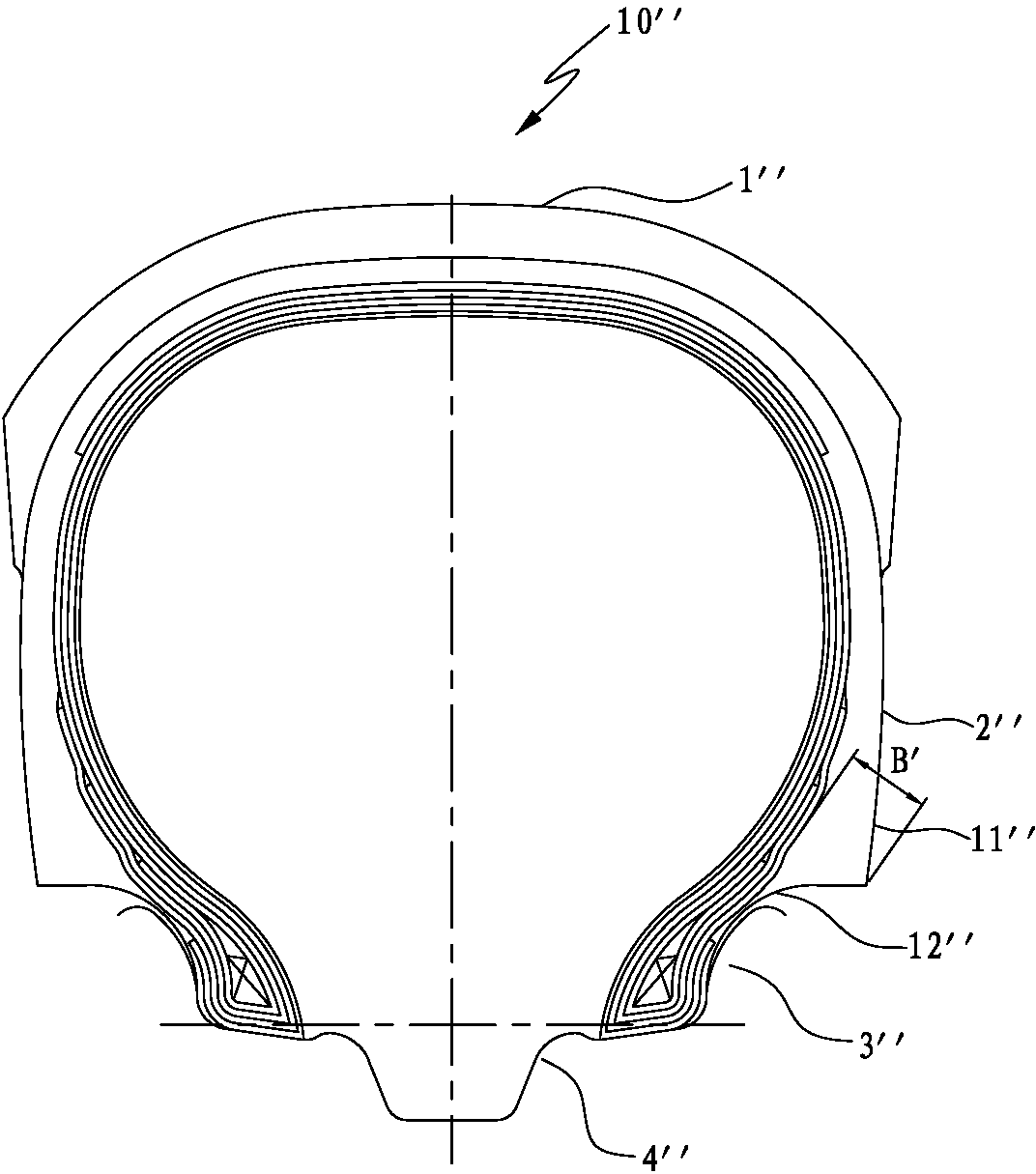

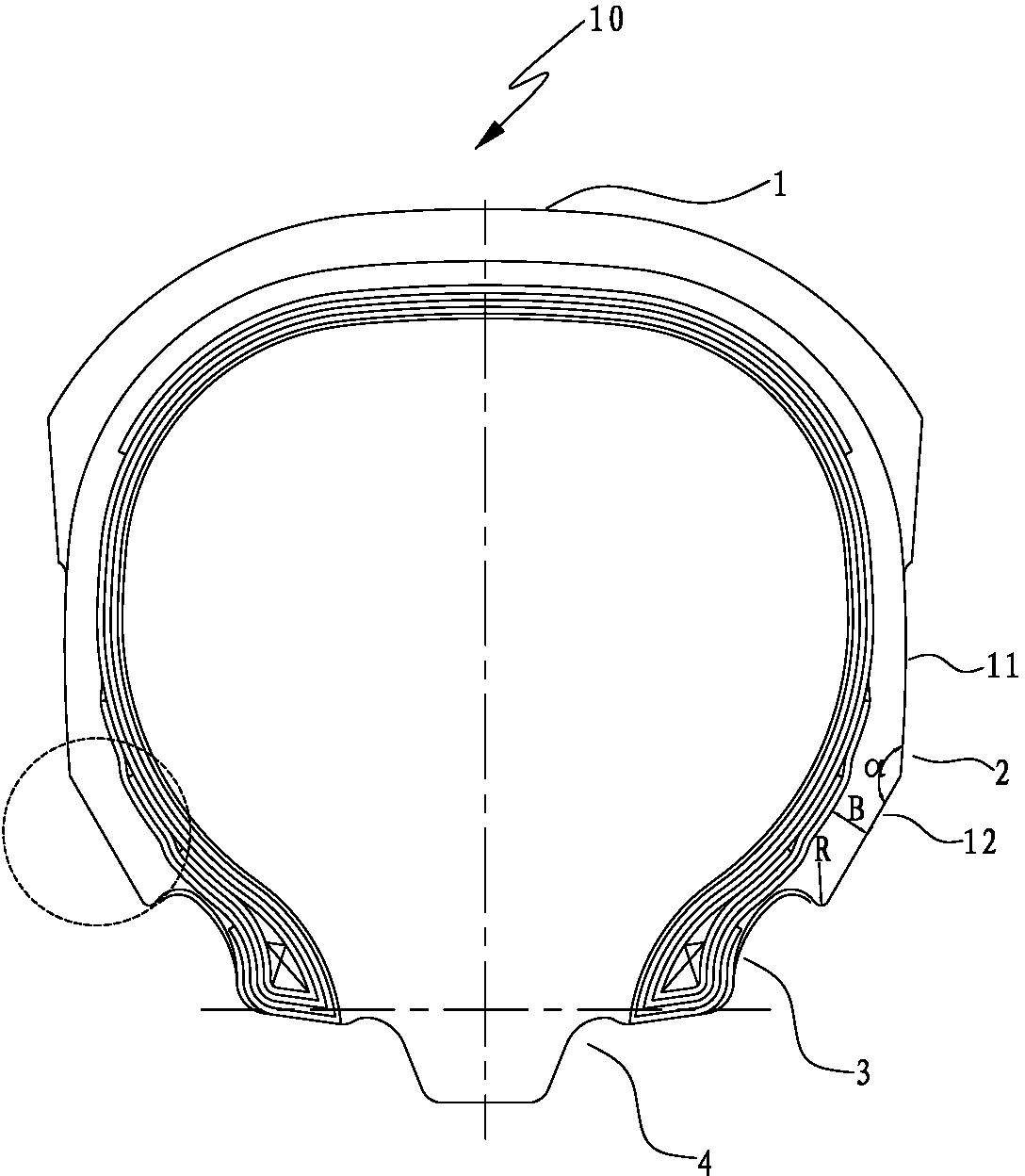

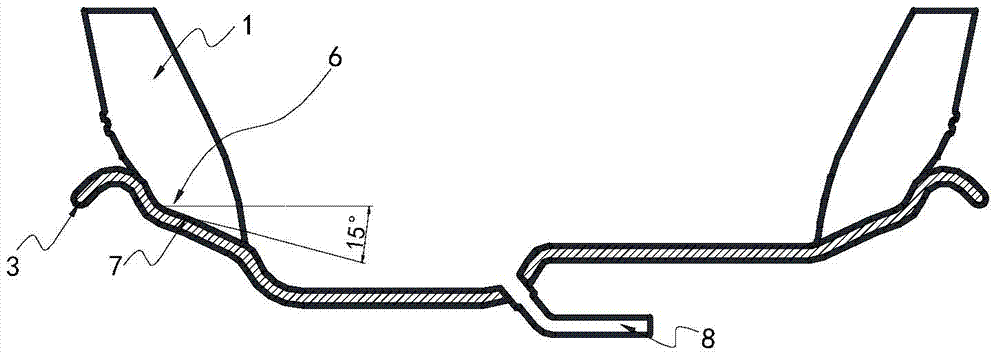

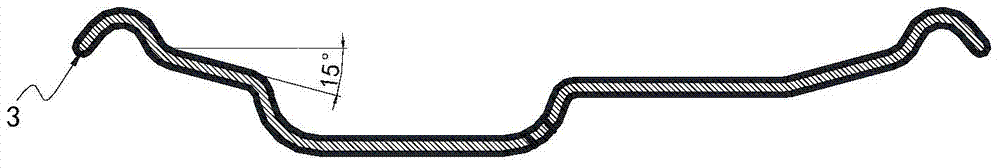

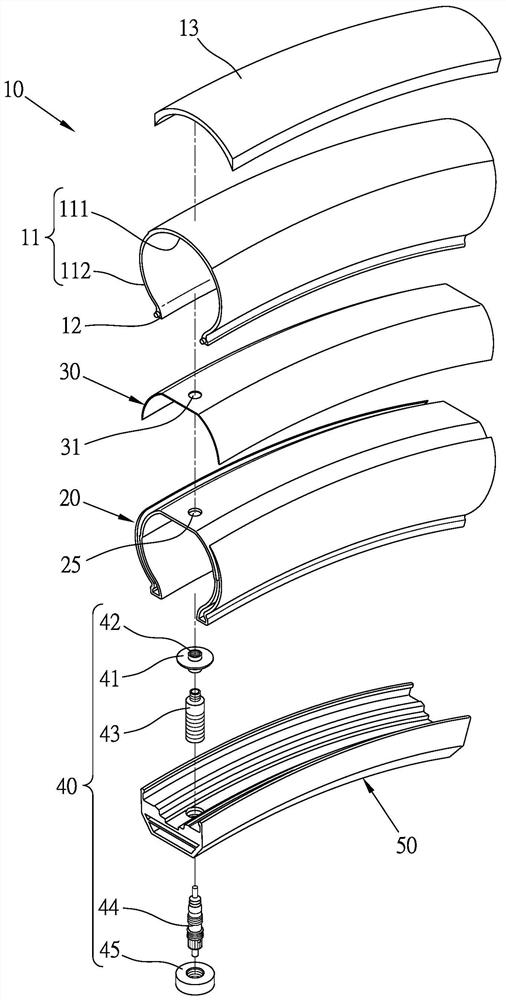

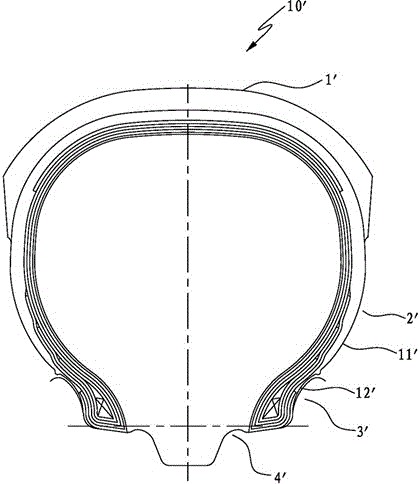

Section structure of motorcycle tire

InactiveCN103407330AReduce weightGuaranteed StrengthPneumatic tyre reinforcementsTyre beadsTweelInternal pressure

The invention discloses a section structure of a motorcycle tire. The motorcycle tire comprises a tire tread part, a tire bead part and a tire lip part, wherein the tire bead part consists of an upper circular arc line and a lower straight line; an included angle formed between the circular arc line and the straight line is an obtuse angle; saw-toothed patterns are arranged all around the straight line; the tire bead part and the tire lip part are chamfered. The tire bead part which consists of the circular arc line and the straight line is approximate to a broken line, so that the rigidity of the tire bead part is ensured, the tire and a rim can be well embedded, and the problem of separation of the tire lip part from the rim is solved; moreover, by additionally arranging the saw-toothed patterns on the straight line of the tire bead part, the whole weight of the tire can be reduced; by chamfering the tire bead part and the tire lip part, stress concentration between the tire bead part and the tire lip part can be prevented, and the strength of the tire bead part can be ensured; when the tire runs in an internal pressure reduction state, the tire can be fastened with the rim, the air preservation performance is improved, and a motorcycle can reach the nearest maintenance point.

Owner:CHENG SHIN RUBBER XIAMEN IND

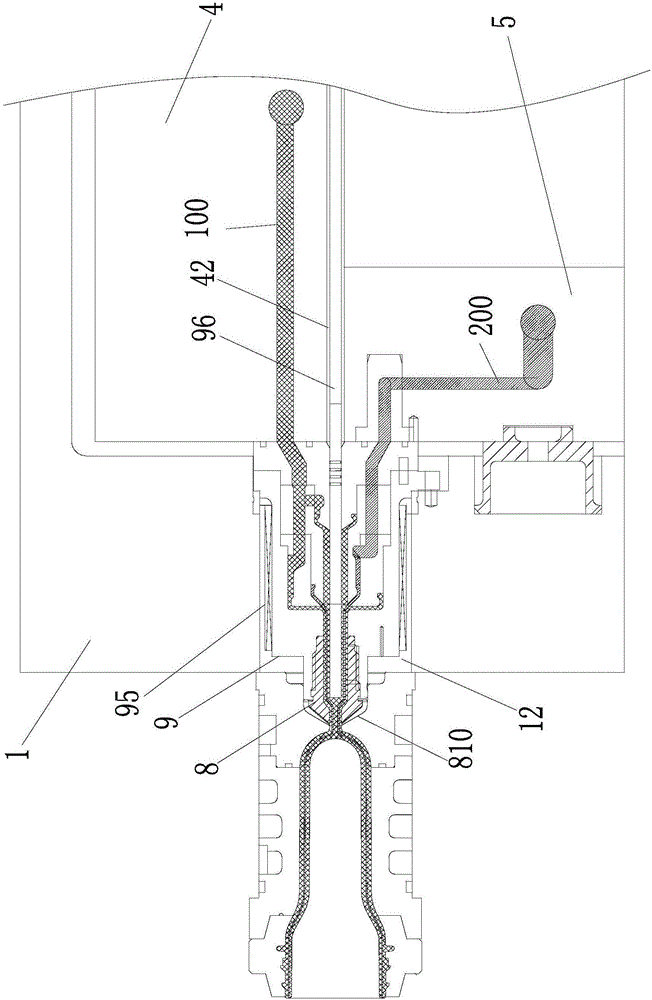

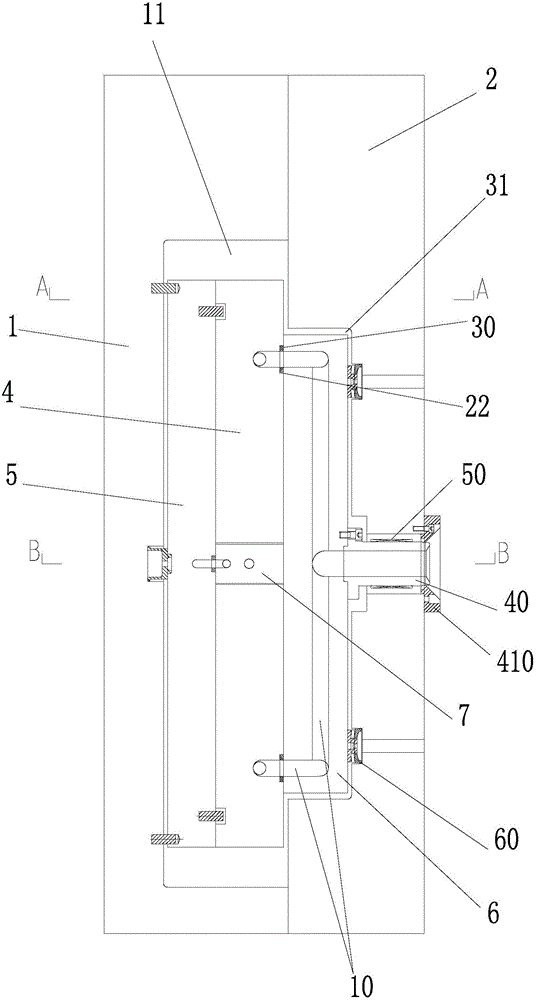

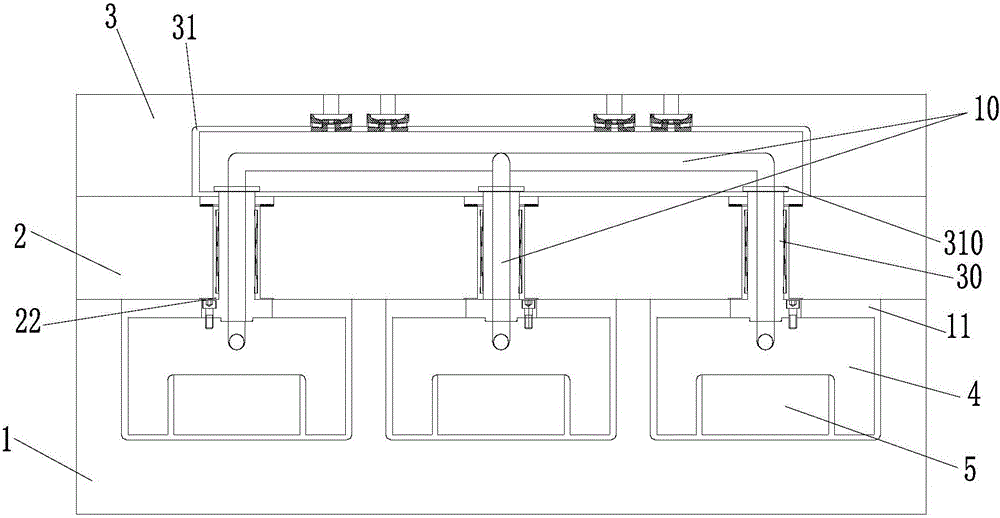

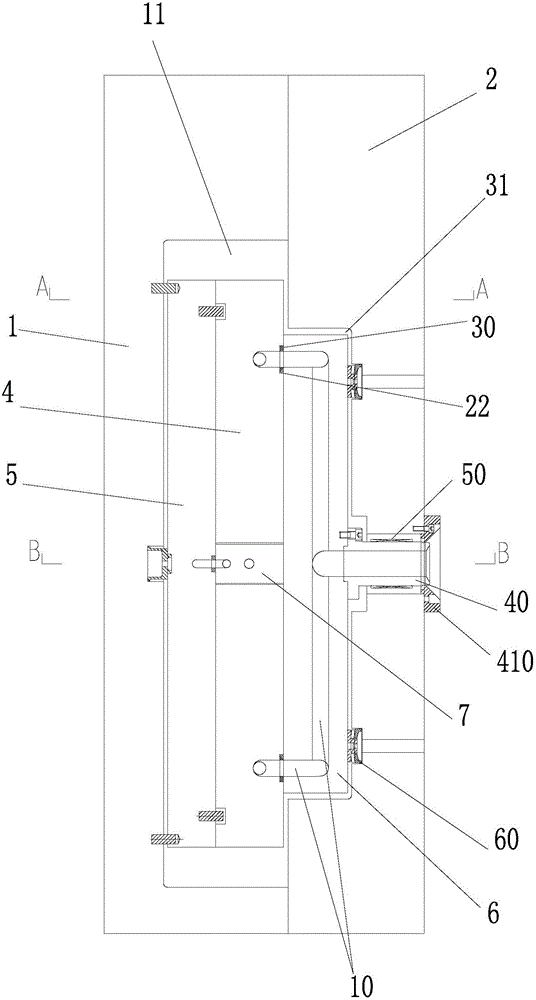

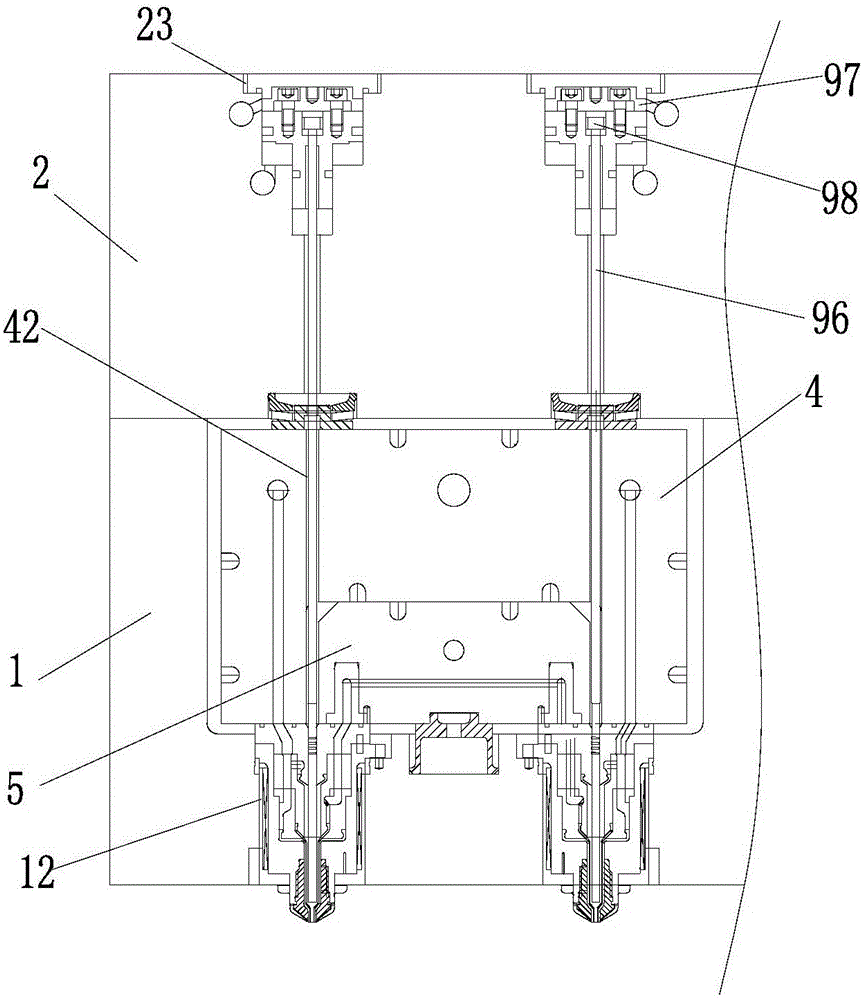

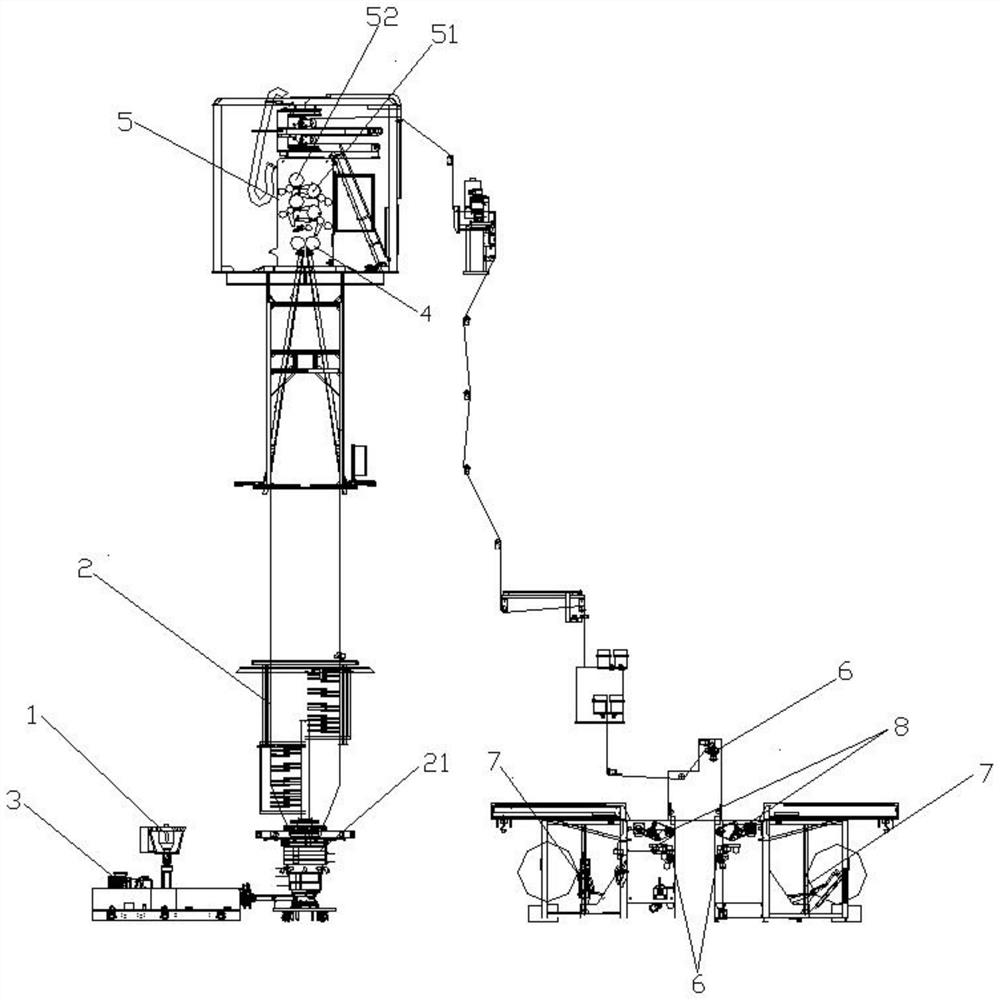

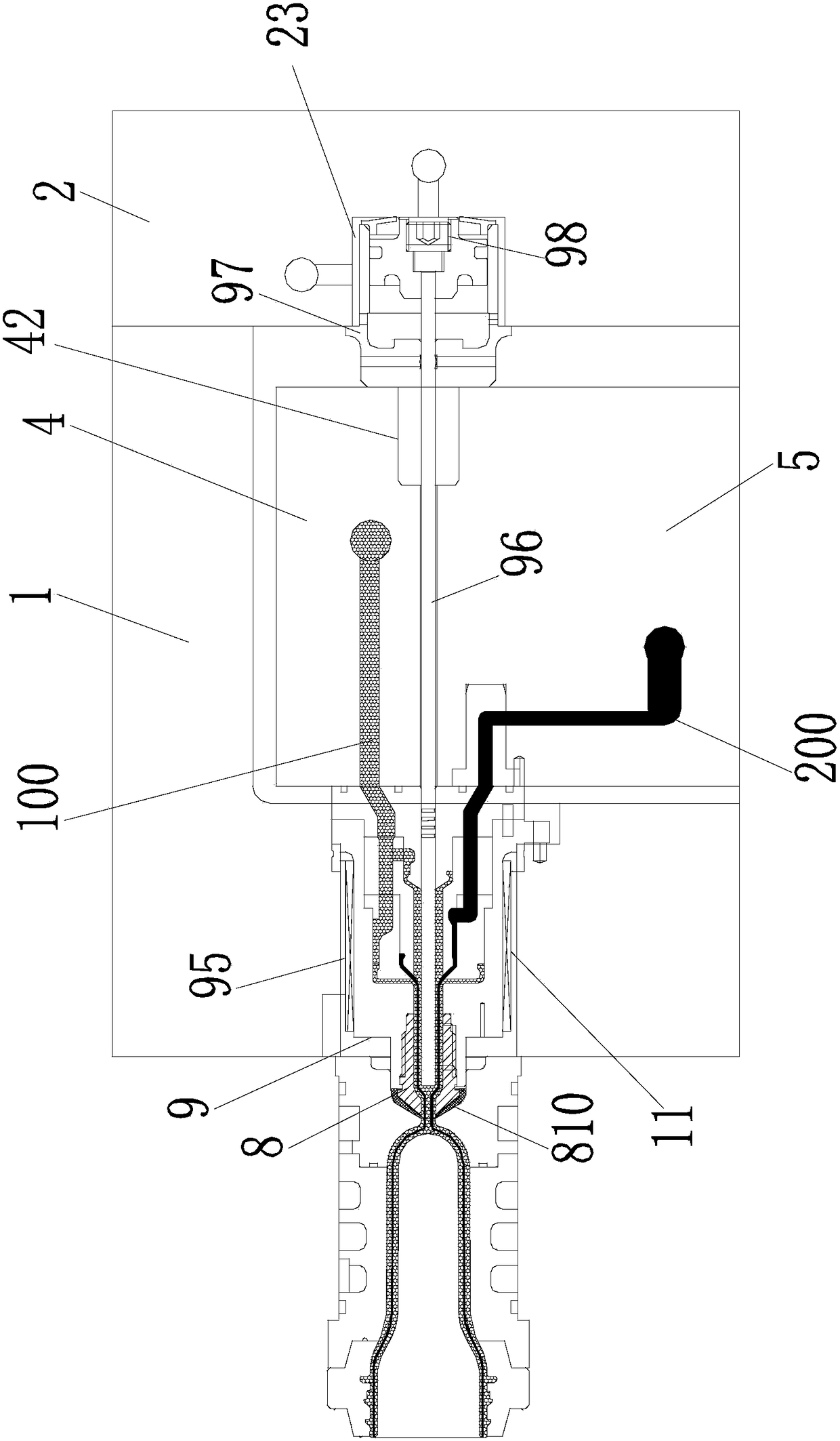

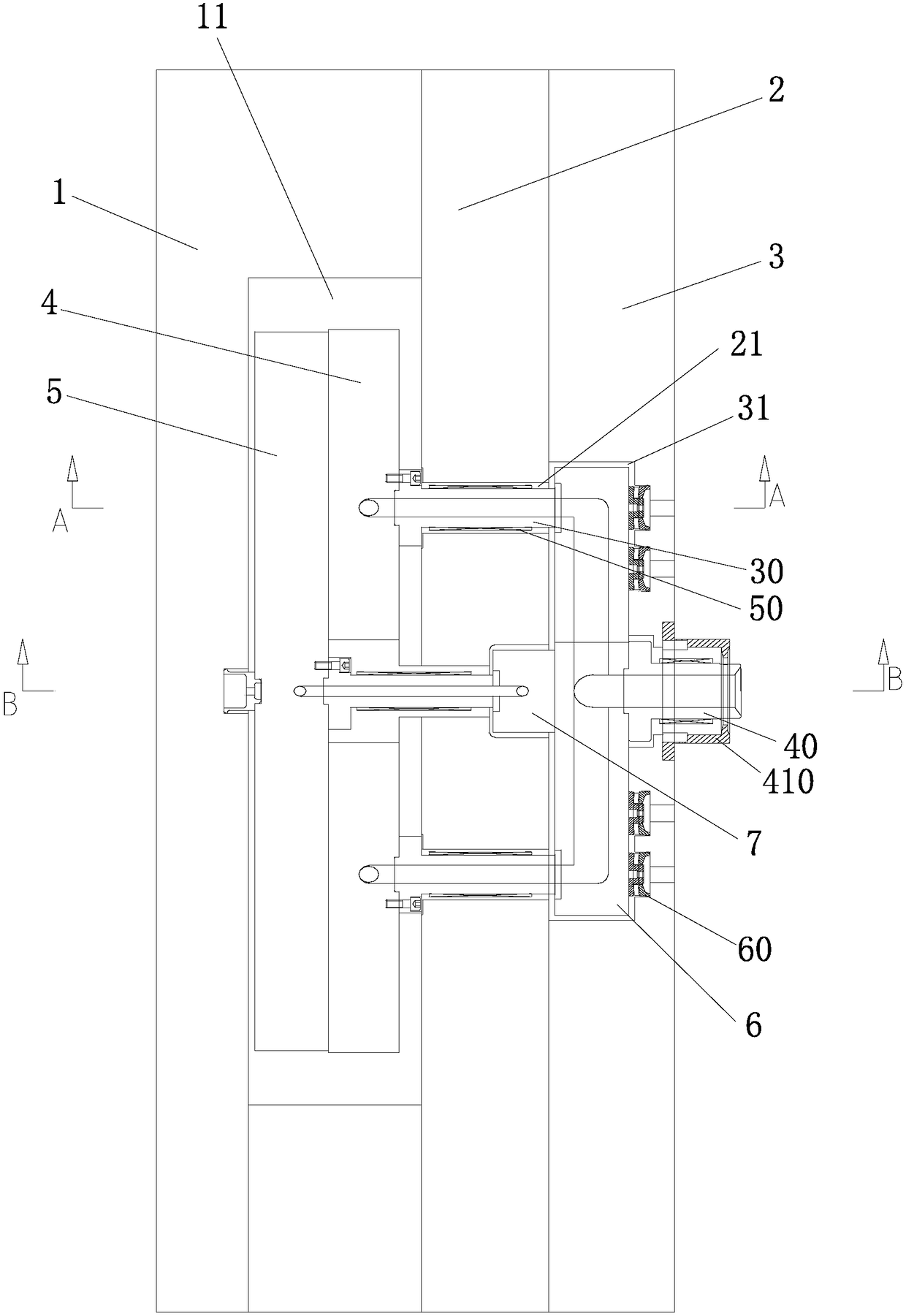

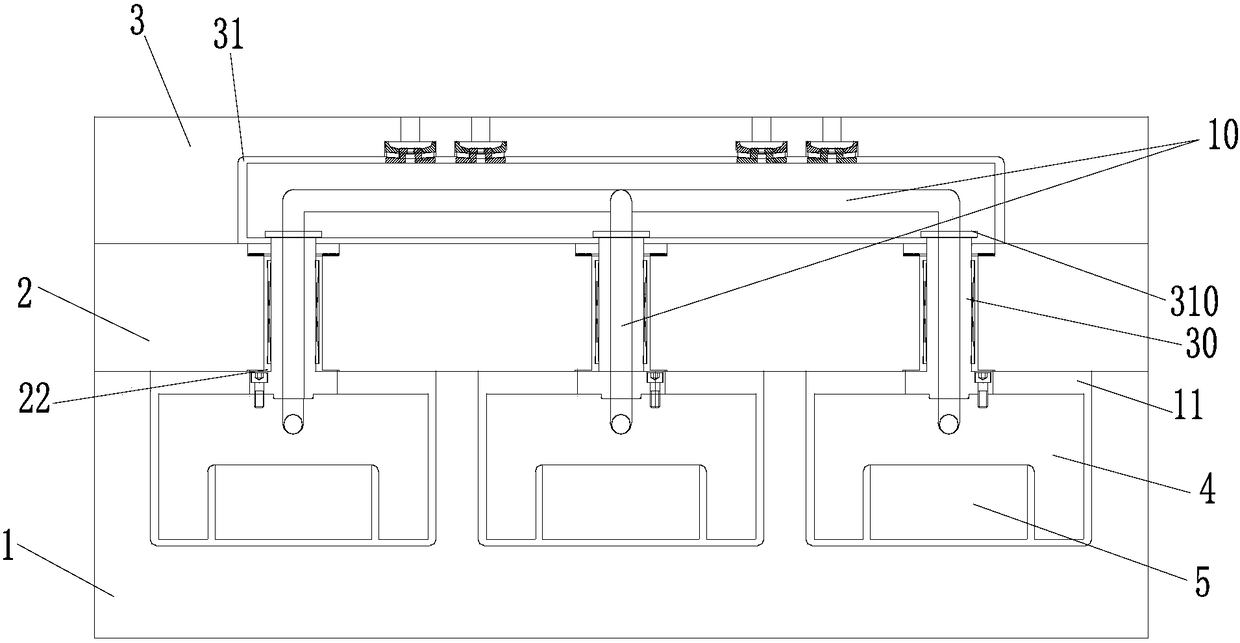

Hot-runner mold provided with double layers of runners

ActiveCN105965789AImprove gas retention performanceGood physical and mechanical propertiesDomestic articlesHollow articlesHot runnerMolten state

The invention discloses a hot-runner mold provided with double layers of runners. The mold comprises a runner plate structure, wherein the runner plate structure comprises a transition plate and an air cylinder plate; a first surface-layer runner plate and a first core-layer runner plate are arranged between the transition plate and the air cylinder plate; a first surface-layer melt runner is arranged inside the first surface-layer runner plate; a first core-layer melt runner is arranged inside the first core-layer runner plate; a second surface-layer runner plate and a second core-layer runner plate are further arranged between the transition plate and the air cylinder plate; a second surface-layer melt runner is arranged inside the second surface-layer runner plate; and a second core-layer melt runner is arranged inside the second core-layer runner plate. The mold adopts the design of the double layers of runners, that is, the surface-layer melt runners comprise double layers of runners capable of realizing independent temperature control, and the core-layer melt runners also comprise double layers of runners capable of realizing independent temperature control, so that plastic in different molten states can be injected into a cavity in a layered manner simultaneously, and different materials can be injected on the same bottom preform in a layered manner.

Owner:GUANGZHOU HUAYAN PRECISION MACHINERY

Formula for reducing tire bead protection rubber heat generation performance and compression deformation

The invention discloses a formula for reducing tire bead protection rubber heat generation performance and compression deformation. The formula comprises 100phr of natural rubber, 40 to 60phr of N326 carbon black, 2 to 5phr of zinc oxide, 1 to 3phr of stearic acid, 0 to 3phr of RD, 3 to 10phr of reinforcing resin, 3 to 5phr of sulphur, 0.5 to 1.0phr of N-cyclohexyl-2-benzothiazole sulfonamide and 1.0 to 2.0phr of hexamethoxymethyl melamine resin. The rubber prepared by the rubber formula provided by the invention has the advantages that the dynamic heat generation performance and compression deformation of the rubber material can be further reduced, so that the tire bead protection rubber and a wheel rim are perfectly matched in the dynamic state; the durable driving performance of the tire is ensured; the air preservation performance is obviously improved; the accident risks of tire ring bubbling and cracking possibly occurring in the use process of the tire are reduced.

Owner:SICHUAN YUANXING RUBBER

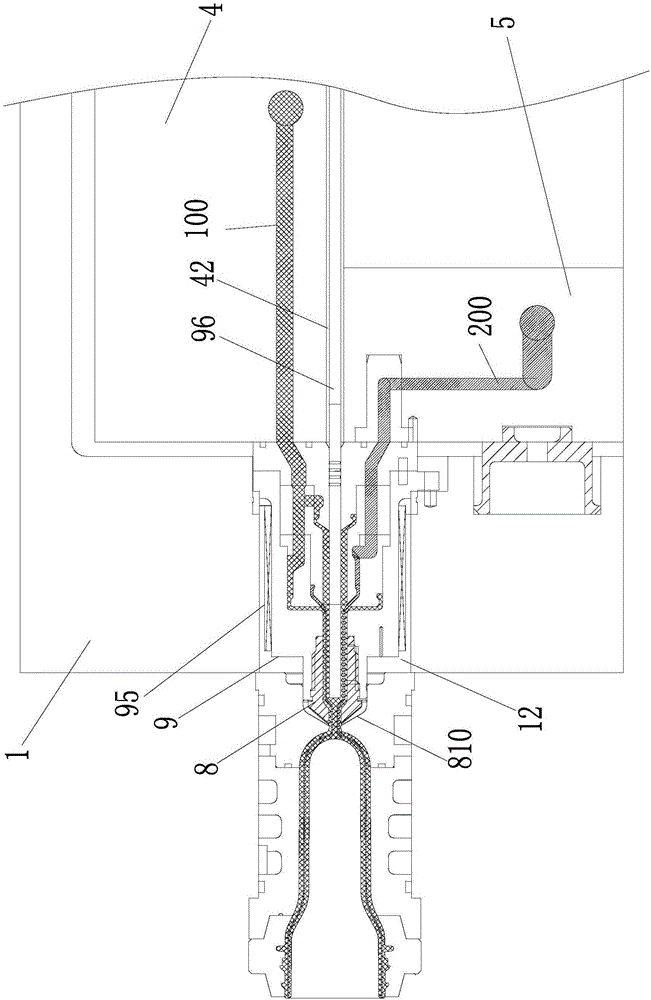

Rubber material for connecting butyl inner tube and inflating valve and preparation method thereof

InactiveCN112011131AHigh bonding strengthImprove gas retention performanceRubber materialPolymer science

The invention provides a rubber material for connecting a butyl inner tube and an inflating valve. The rubber material is composed of the following components in parts by weight: 80 to 120 parts of butyl rubber, 30 to 80 parts of soft carbon black, 5 to 30 parts of an activator, 5 to 35 parts of petroleum resin, 0.5 to 15 parts of tackifying resin, 2 to 22 parts of white carbon black, 0.2 to 3 parts of a coupling agent, 0.5 to 8 parts of an accelerant and 0.5 to 6 parts of insoluble sulfur. A preparation method of the rubber material for connecting the butyl inner tube and the inflating valvecomprises the following steps: S1, burdening; S2, internal mixing; S3, bolt lifting ; S4, bolt pressing; S5, feeding of master batch into an internal mixer; and S6, feeding of air-mixed rubber, the accelerant and the insoluble sulfur into the internal mixer. Due to the adoption of the above technical scheme, the bonding strength between the butyl inner tube and the inflating valve is high, the situation that the edge of the inflating valve is torn is avoided, the air-retaining property of the inner tube is improved, and the service life of the inner tube is prolonged.

Owner:TIUMSUN RUBBER TIRE WEIHAI

Gluten-free cereal cakes and making method thereof

InactiveCN109479936AImprove textureIncrease in sizeDough treatmentBakery productsBaking powderNutrient

The invention provides gluten-free cereal cakes and a making method thereof, and belongs to the technical field of foods. The gluten-free cereal cakes are made from the following raw materials in parts by weight of 0.2-0.5 part of gluten-free cereals, 0.2-0.5 part of eggs, 0.2-0.5 part of granulated sugar, 0.03-0.32 part of soybeans, 0.03-0.17 part of vegetable fat, 0.0008-0.012 part of transglutaminase, 0.0008-0.022 part of lactobacilli, 0.0048-0.022 part of yeast, 0.0008-0.0048 part of baking powder, 0.0008-0.027 part of NaCl, and 0.005-0.06 part of water. The gluten-free cereal cakes provided by the invention are soft, elastic, smooth when being eaten, and rich in nutrients.

Owner:BOHAI UNIV

Initiator of building material and preparation method and application thereof

InactiveCN102050591AReduce surface tensionEnhance gas retention capacitySolid waste managementCeramicwareSolid phasesSurface tension

The invention discloses an initiator of a building material and a preparation method and application thereof. The initiator comprises calcium stearate, aqueous solution of sodium hexametaphosphate, and fly ash. The initiator can effectively reduce the surface tension of a light building material slurry system, enhances the gas retention capacity of slurry and is favorable for ensuring that foamed pores formed in the foaming process of the slurry in gas, liquid and solid phase states are stable and uniformly distributed and have a closed pore structure; in addition, the pore size of the foamed pores can be adjusted by controlling the addition amount of the initiator. By the initiator, various light building materials with different components, different volume weight, different compression strength, different heat conduction coefficients and different application can be prepared, so that various properties of the light building materials can be obviously improved, and the requirements of modern rooms on the thermal insulation property, sound insulation property, energy saving property and the like of the building materials are met.

Owner:张林山

Temperature-resistant chocolate ice cream and preparation process thereof

InactiveCN107927314AGreat tasteReduce restrictionsFrozen sweetsGaseous food ingredientsProcess engineeringIce cream

The invention discloses temperature-resistant chocolate ice cream. The ice cream is prepared from a wafer cone, chocolate soft sauce filling the wafer cone and aerated chocolate sauce arranged at thetop of the chocolate soft sauce. Unlike a traditional ice cream product which can only be stored in an environment at minus 18 DEG C and below, the temperature-resistant chocolate ice cream can be stored and transported at normal temperature and has less limitation to the selling environment, and the cost for storage and transportation can be reduced. Furthermore, the chocolate soft sandwich sauceis arranged at the bottom of the temperature-resistant chocolate ice cream, and the aerated chocolate sauce is arranged at the top of the temperature-resistant chocolate ice cream, so that the ice cream has the taste of crispy and smooth chocolate and the taste of soft and rich chocolate soft sauce, the taste of the chocolate ice cream is remarkably improved, and the ice cream is richer in structure. The invention further discloses a process for preparing the temperature-resistant chocolate ice cream. By adopting the process, the density of the chocolate sauce is reduced from 1.2kg / L to 0.6-0.7kg / L, and the chocolate ice cream having room-temperature resistance can be prepared by a subsequent preparation process. The ice cream can be stored and transported at room temperature, and industrial production of chocolate ice cream cones can be realized.

Owner:南京喜之郎食品有限公司

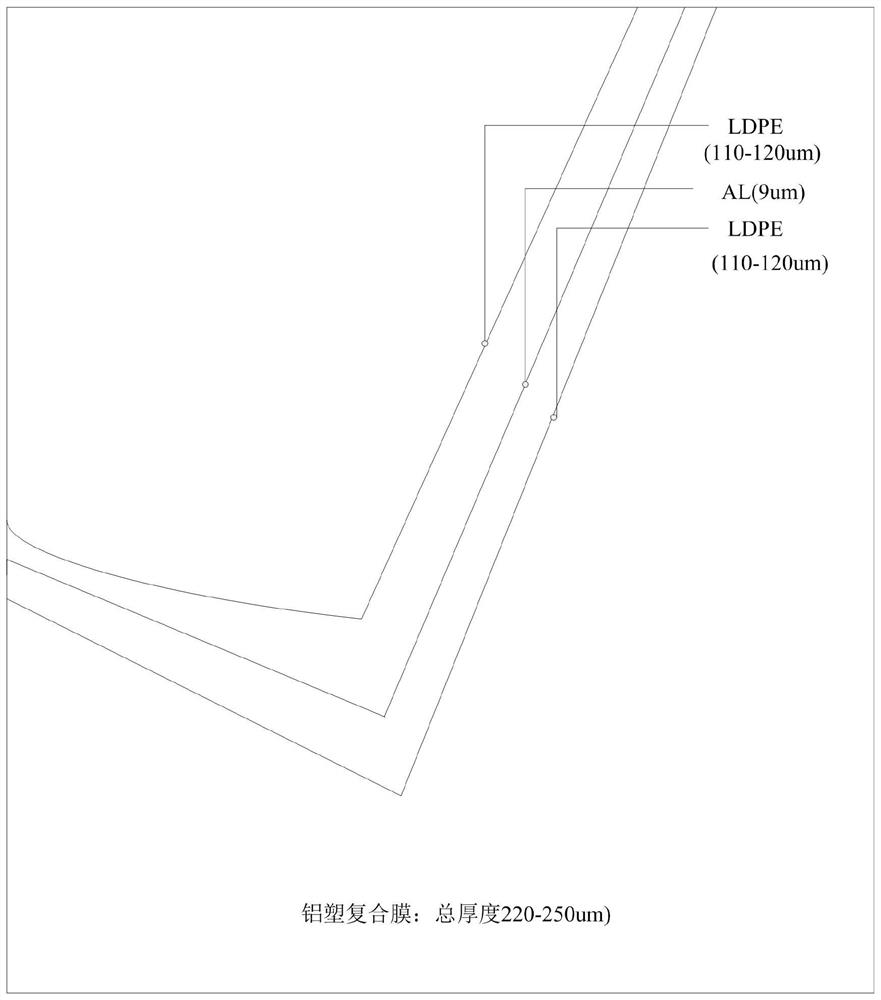

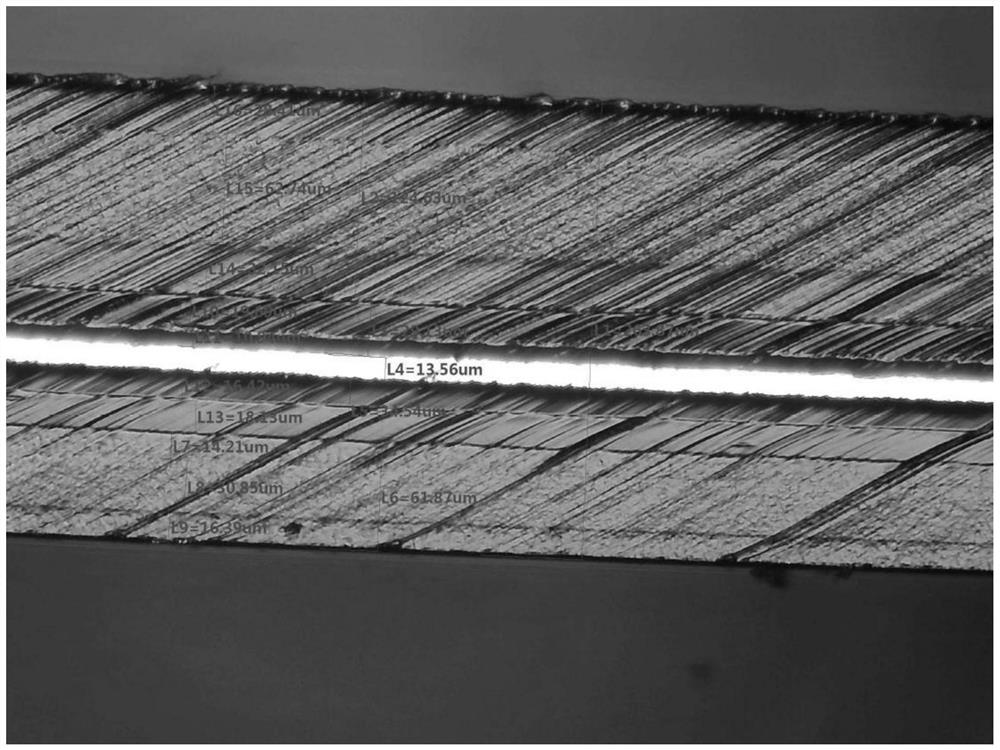

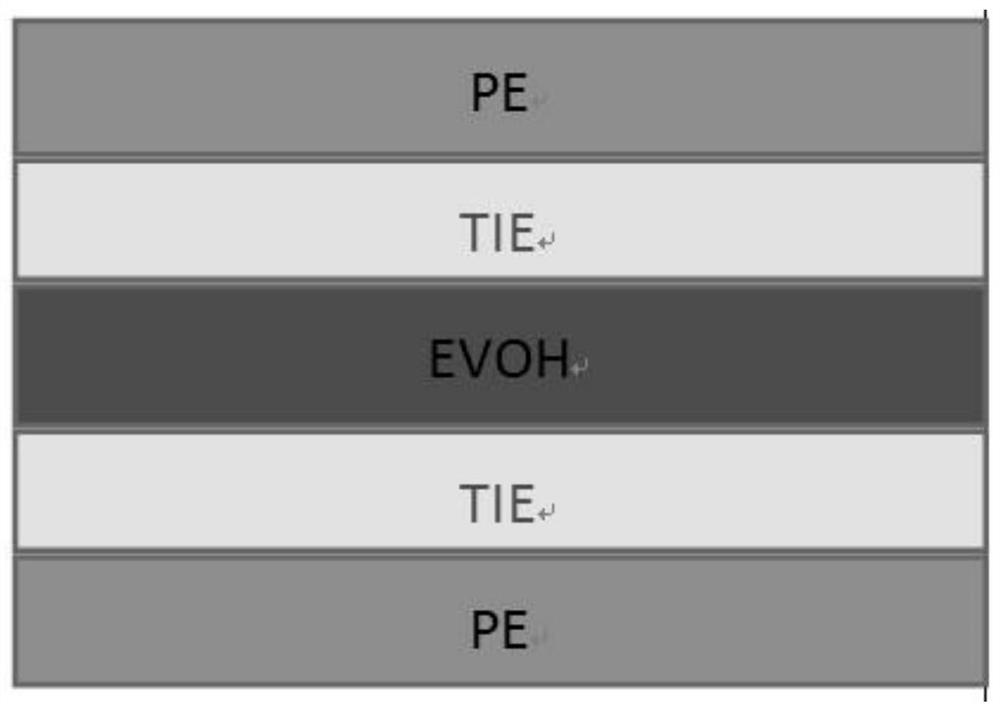

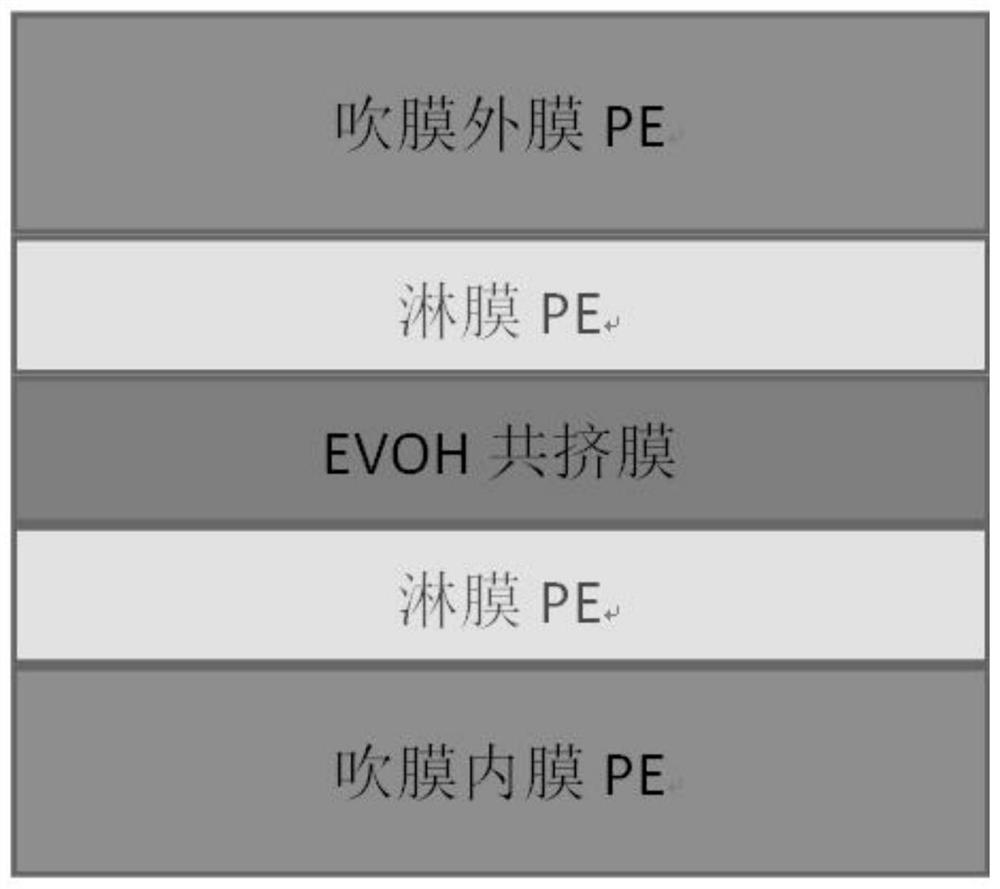

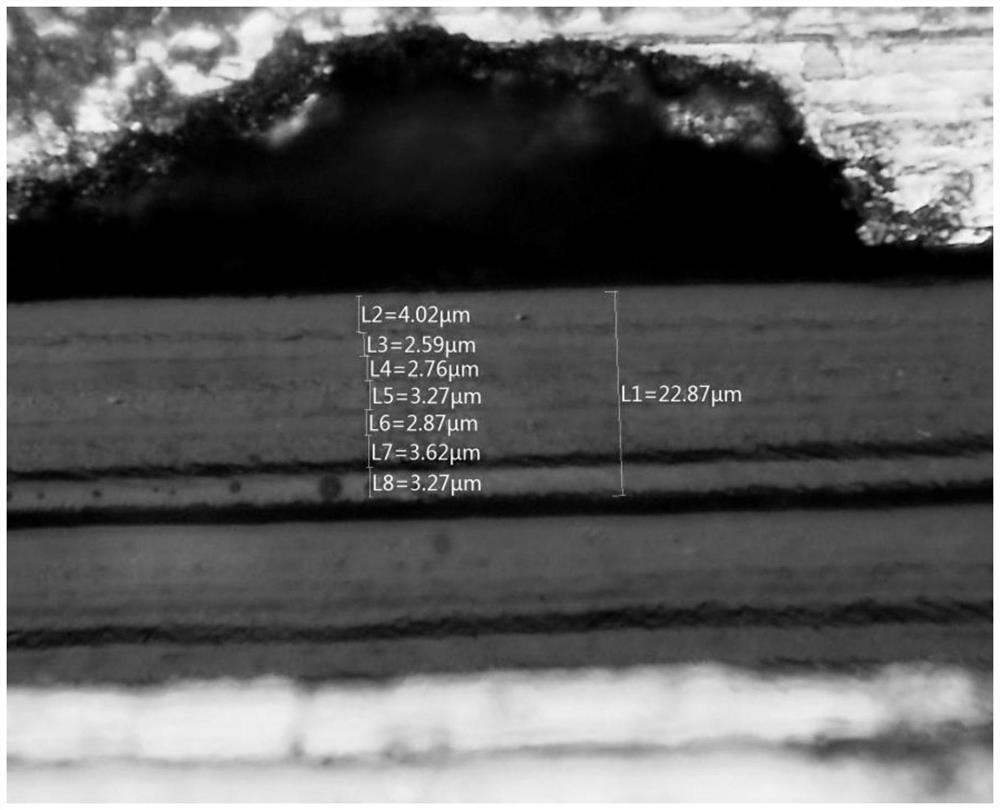

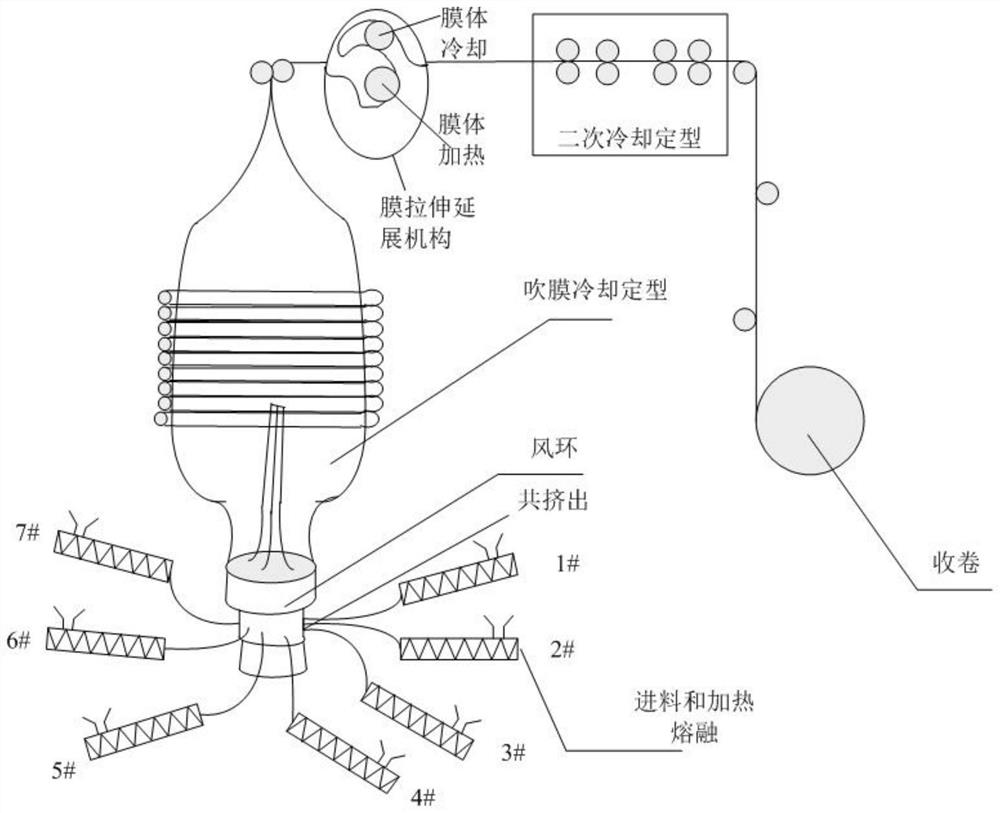

Recyclable high-oxygen-barrier film material and preparation method thereof

ActiveCN112477341AImprove barrier propertiesHigh strengthPackage recyclingSynthetic resin layered productsPolymer sciencePolyolefin

The invention discloses a recyclable high-oxygen-barrier film material. The recyclable high-oxygen-barrier film material comprises a first polyolefin functional layer, a second polyolefin functional layer and an ethylene-vinyl alcohol copolymer intermediate barrier layer, wherein the total thickness of the high-oxygen-barrier film material is 150-400 microns, a film layer structure displayed undera microscopic electron microscope comprises only one ethylene-vinyl alcohol copolymer intermediate barrier layer, the layer thickness ratio of the intermediate barrier layer is 10% or below, and theoxygen permeability test value of the membrane material is less than 1 cm<3> / m<2>. day. A preparation method for the film material comprises a plurality of the following steps: feeding; heating and melting; co-extrusion; film blowing, cooling and shaping; traction; rolling; and the like. In the stage of film blowing, cooling and shaping, all the film layers are obtained through one-shot film blowing and shaping; thick film stretching and extending operation is additionally carried out once in the process of traction; and the number of runners of a die head of the film blowing machine is kept consistent with the number of layers of the high-oxygen-barrier film material to be prepared, and the opening size of the runners is widened so as to realize correspondence to the layer thickness ratio. A product prepared in the invention can better maintain high oxygen resistance and high water resistance of the film material, realizes all-plastic compounding, and can be recycled.

Owner:GUANGDONG FORETURE NEW MATERIAL CO LTD

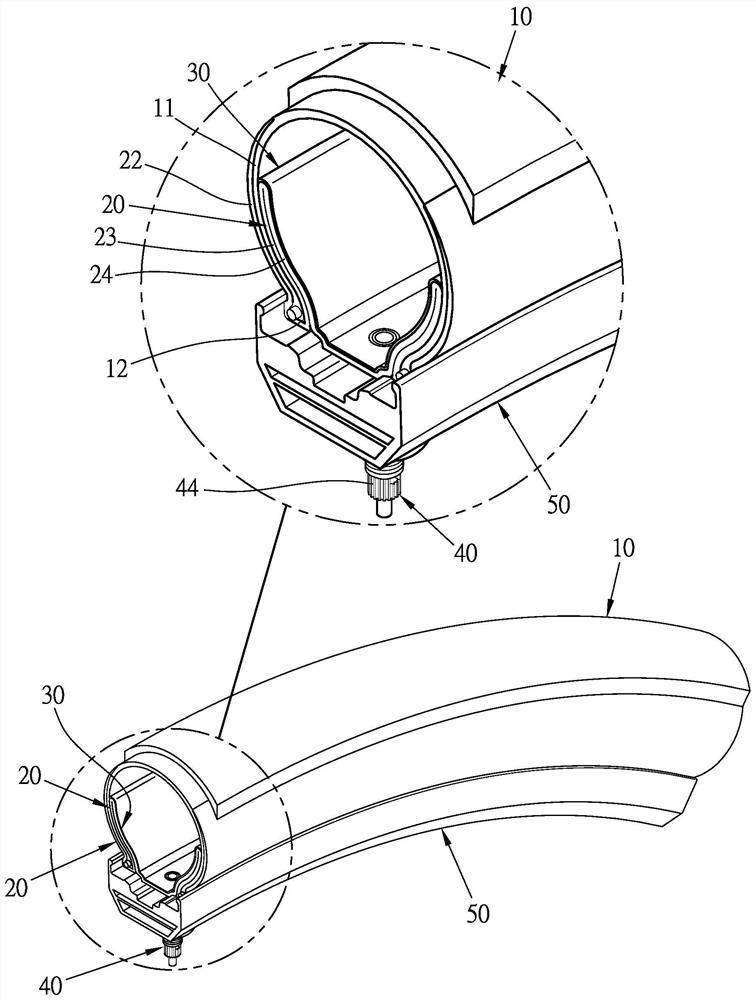

Wheel assembly for load-carrying vehicle

The invention discloses a wheel assembly for a load-carrying vehicle. The wheel assembly comprises a tubeless tyre and a rim. The wheel assembly is characterized by further comprising an inner tube installed in a cavity of the tubeless tyre and a blanket, wherein the inner tube is located between the blanket and the tubeless tyre. The rim is a one-piece 15 degree deep groove rim or an independently designed multi-piece 15 degree deep groove rim. The blanket is designed according to dimensions of the rim and the inner contour of the tubeless tyre. The inner tube is designed according to dimension of inner contours of the tubeless tyre, the rim and the blanket. According to the wheel assembly for the load-carrying vehicle disclosed by the invention, the overall loading capacity, the durability, the impact puncture resistance and the gas protecting performance of the tyre assembly are improved, applicability of the tubeless tyre on various road conditions is expanded, and the problem that the rim of the tubeless tyre is easy to deform or air leakage in mine lots or bad roads caused by the upwarp of the tire bead and the bead toe is solved.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

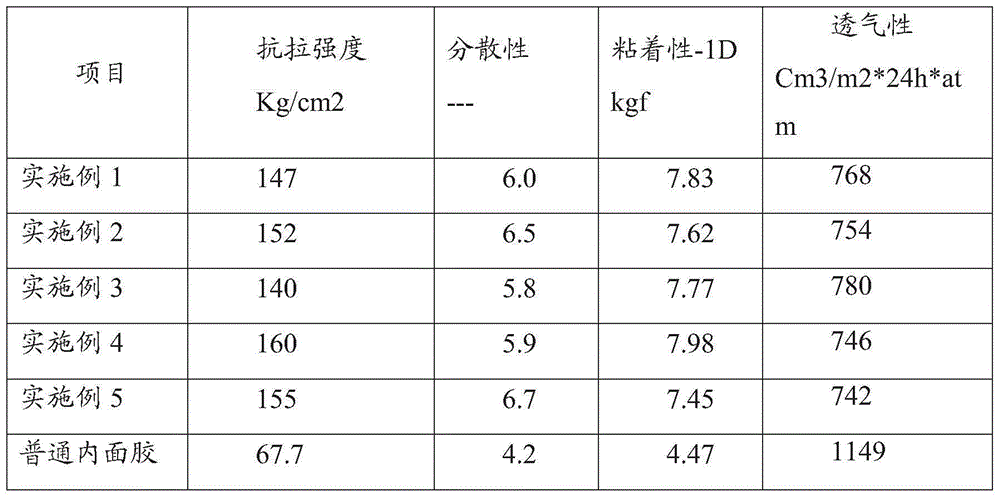

High-gas-maintaining-performance inner surface rubber and synthesis method of high-gas-maintaining-performance inner surface rubber

InactiveCN105017582AIncrease dosageReduce dosageNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceEmulsion

The invention provides high-gas-maintaining-performance inner surface rubber, which comprises the following ingredients in parts by weight: natural rubber, emulsion polymerized styrene butadiene rubber, chlorinated butyl rubber, high-wear-resistance carbon black, general furnace black, flaky nanokaolin, chemical anti-aging agents BLE-W, active agents of ZnO, active agents of stearic acid, tackifying resin RT-1102, sulfurization agents S-325, promoting agents TB710, promoting agents TBBS, promoting agents TMTD and operation oil TDAE-22. The high-gas-maintaining-performance inner surface rubber has the advantages that the cost is low; the gas maintaining performance is high; the processing dispersivity and the adhesive property are improved; the physical performance is also improved; meanwhile, the consumption on petroleum products is also reduced; certain environment-protection effects are achieved.

Owner:KENDA RUBBER CHINA

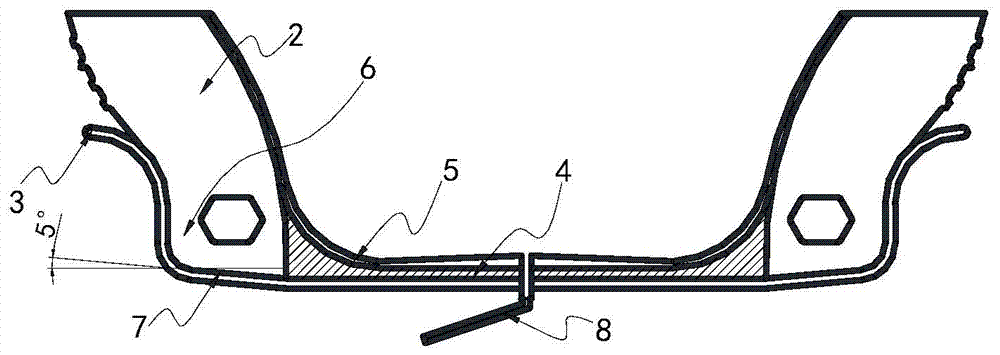

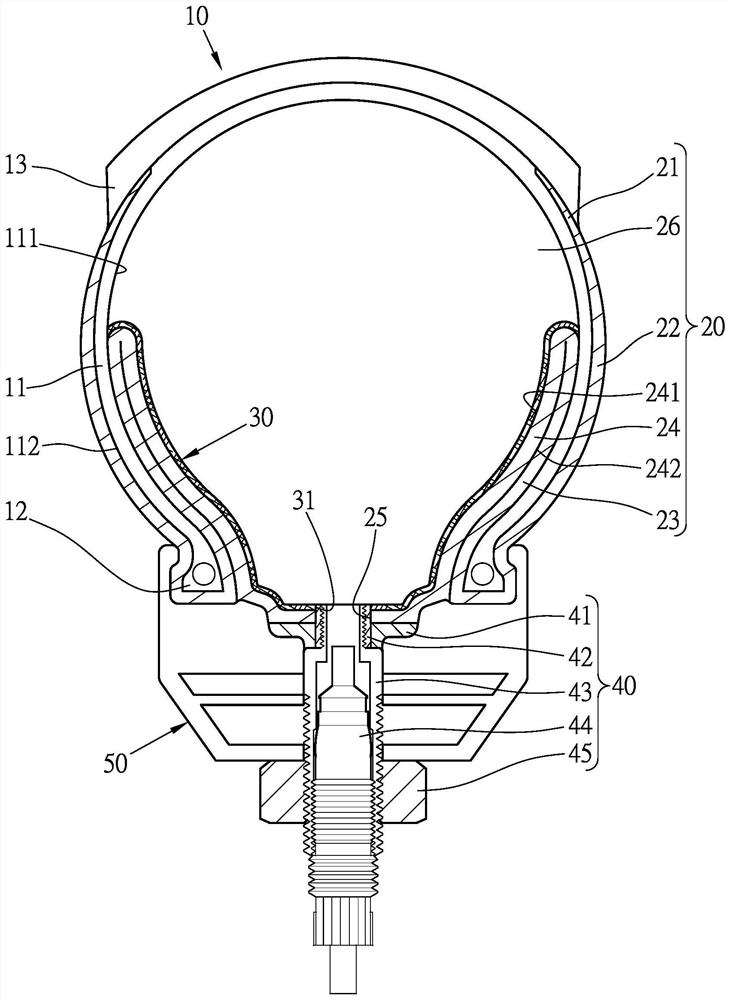

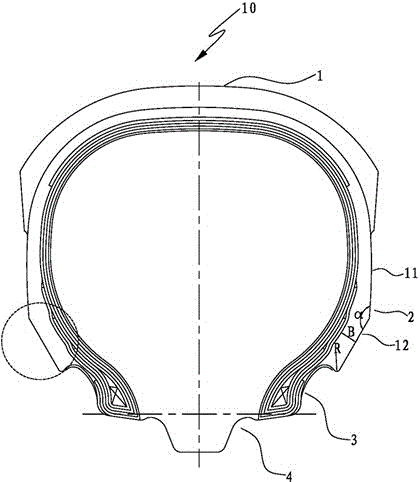

Pneumatic Tubeless Tires

ActiveCN110450581BImprove gas retention performanceIncreased durabilityWithout separate inflatable insertsTubeless tireAutomotive engineering

The present invention mainly provides a pneumatic tubeless tire, comprising: a carcass, the lower edges of both sides of the carcass are respectively provided with a bead; a coating layer, which continuously covers the bead to the carcass. Inside the carcass, the two ends of the cladding layer are respectively set as an overlapping portion, which is arranged between each carcass and the crown, and the parts on both sides of the cladding layer that are attached to the carcass are respectively set as an inner cladding portion. , each inner surface and cladding layer located in the carcass jointly form a gas chamber; at least one separator is partially arranged on the wall of the gas chamber to isolate the elastic parts and the inner wall of the carcass. And not sticky; an air nozzle group, which is installed between each opening and the through hole, and has a film fixed on the elastic part; an extension piece, which is installed on each film, coating layer and isolation body . The structure design of the cladding layer and the isolation body can improve the rigidity and support of the tire, and improve the durability, air retention and safety.

Owner:CHENG SHIN RUBBER

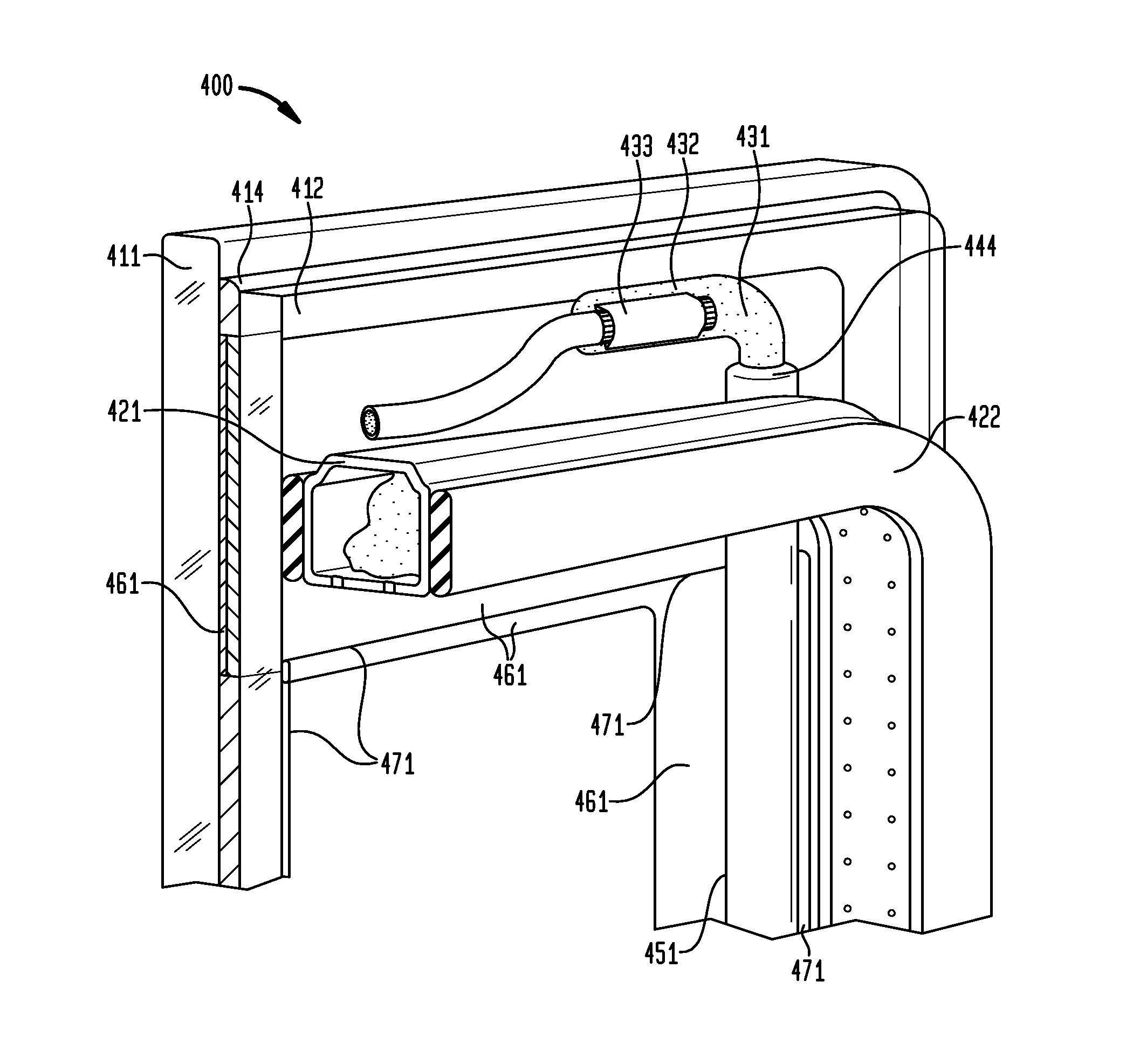

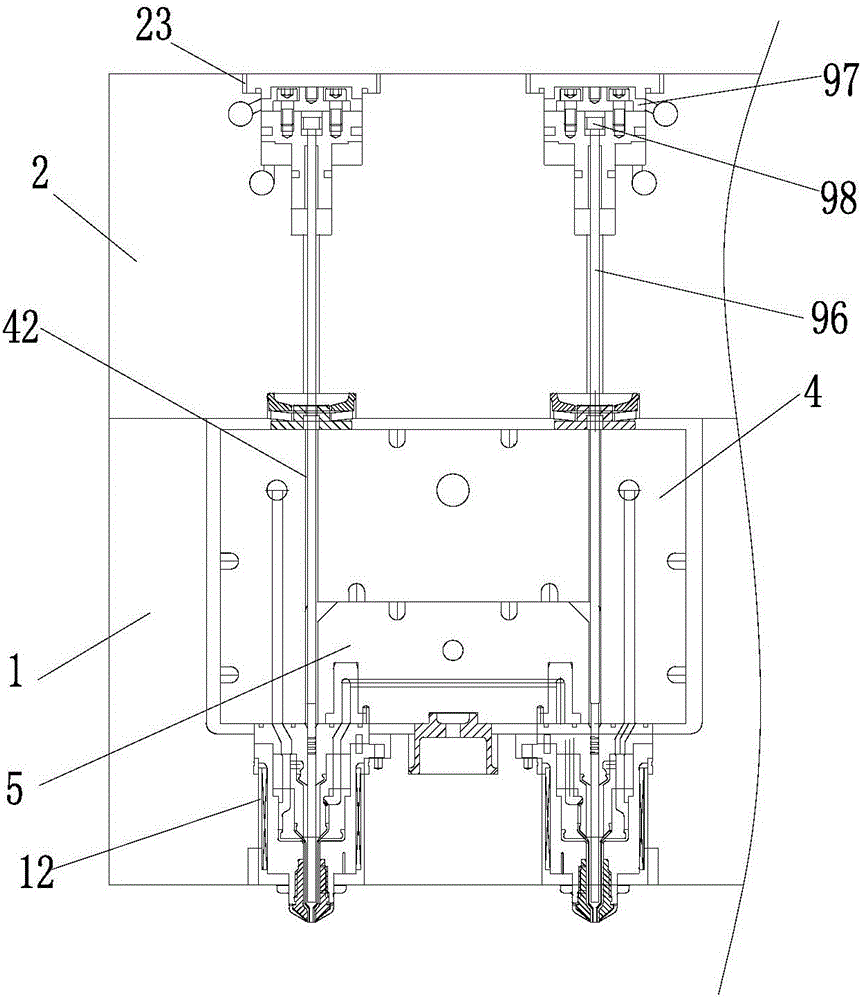

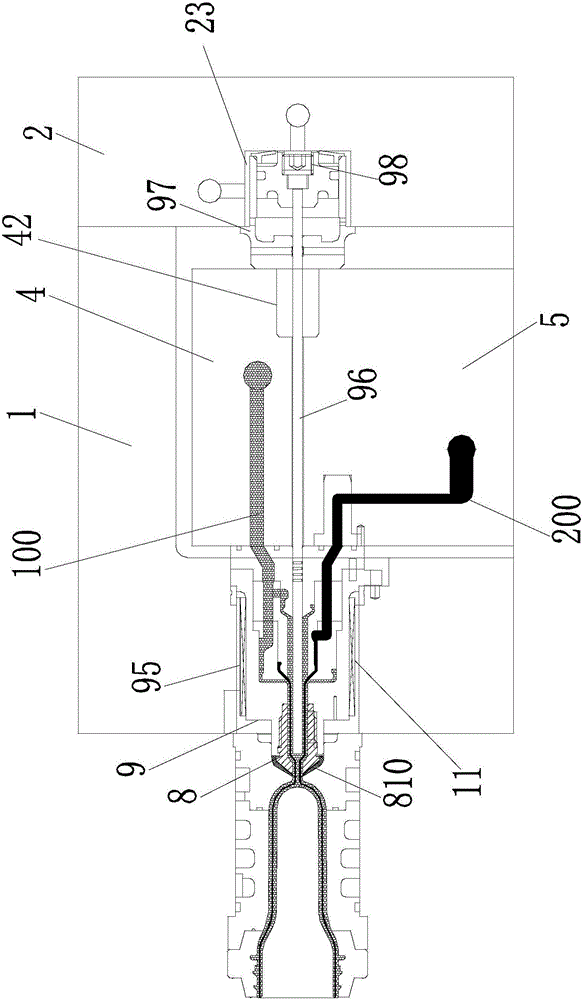

Hot runner mold

ActiveCN106003570AImprove gas retention performanceGood physical and mechanical propertiesDomestic articlesHollow articlesHot runnerSurface layer

The invention discloses a hot runner mold. The hot runner mold comprises a runner plate structure and a spray nozzle structure. The runner plate structure is provided with a surface melt runner and a core layer melt runner. A base comprises an outer surface layer melt passageway, a core layer melt passageway and an inner surface layer melt passageway. Surface layer melt enters the surface layer melt passageway and then enters the outer surface layer melt passageway and the inner surface layer melt passageway of the spray nozzle structure through outlets. Core layer melt enters the core layer melt runner and enters the core layer melt passageway of the spray nozzle structure through an outlet. A discharge port of the core layer melt passageway is located between a discharge port of the outer surface layer melt passageway and a discharge port of the inner surface layer melt passageway. A convergence opening is formed by joining the discharge port of the core layer melt passageway, the discharge port of the outer surface layer melt passageway and the discharge port of the inner surface layer melt passageway. The outer surface layer melt, the core layer melt and the inner surface layer met enter the convergence opening at the same time, then enter an inlet of an injection nozzle and can finally be injected into a mold cavity in a layered manner. The hot runner mold is provided with the multiple layers of runners, different types of molten plastic can be injected into the mold cavity at the same time in a layered manner, and different materials can be injected onto a same bottle blank in a layered manner.

Owner:GUANGZHOU HUAYAN PRECISION MACHINERY

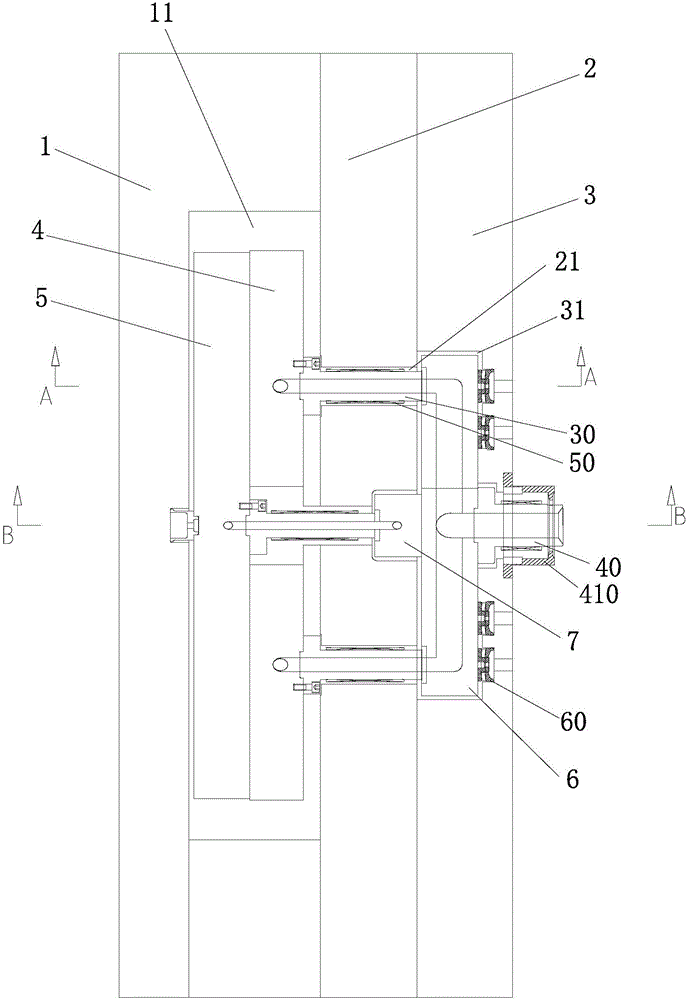

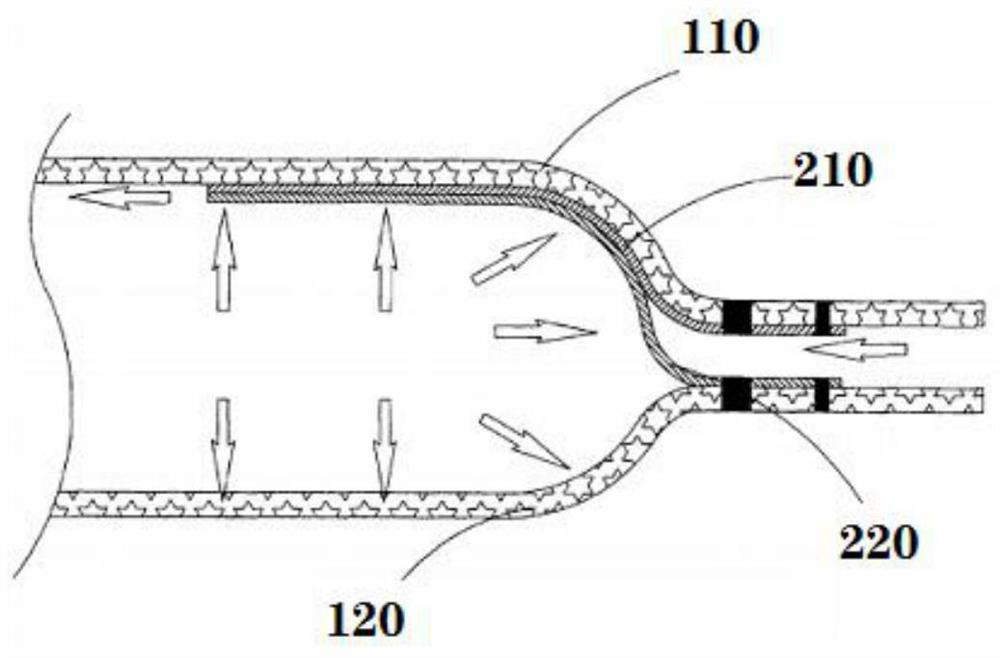

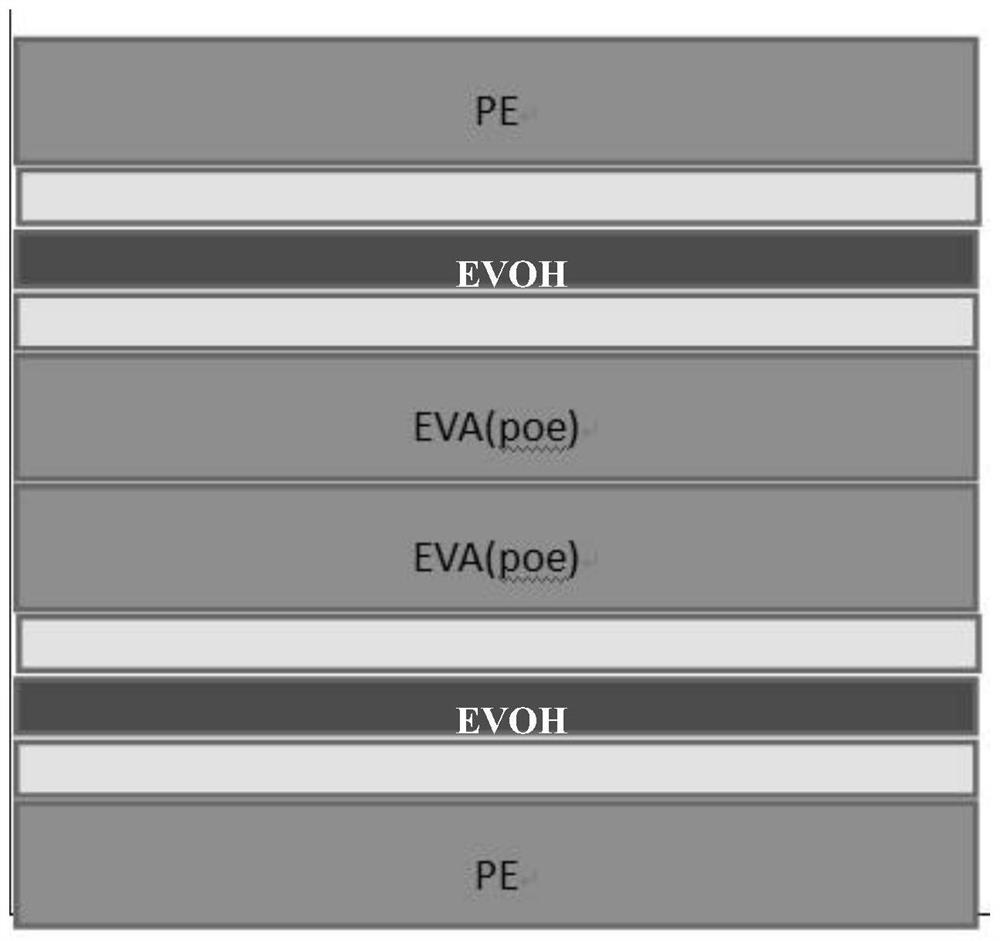

Air valve membrane material, air valve membrane and inflatable bag

PendingCN112356516AImprove barrier propertiesImprove gas retention performancePackage recyclingSynthetic resin layered productsPolymer sciencePolyolefin

The invention discloses an air valve membrane material which is of a multi-layer co-extrusion membrane structure. The material comprises a first polyolefin functional layer, a second polyolefin functional layer and a middle barrier layer, two sides of the middle barrier layer are respectively combined with the first polyolefin functional layer and the second polyolefin functional layer through adhesive resin layers, and the middle barrier layer is a nylon barrier layer and / or an ethylene-vinyl alcohol copolymer barrier layer. The invention further provides an air valve membrane and an inflatable bag which are made of the air valve membrane material, the inflatable bag comprises an upper bottom membrane, a lower bottom membrane and the air valve membrane, the air valve membrane is arrangedat an opening between the upper bottom membrane and the lower bottom membrane, and the upper bottom membrane and the lower bottom membrane adopt membrane materials containing nylon barrier layers or ethylene-vinyl alcohol copolymer barrier layers. The product provided by the invention has better barrier property, significantly improved gas-retaining property, and has the advantages of high strength, puncture resistance, low cost and the like.

Owner:GUANGDONG FORETURE NEW MATERIAL CO LTD

A kind of seafood potato nutritious bread and preparation method thereof

ActiveCN105580866BGood molding effectIncrease softnessDough treatmentPre-baking dough treatmentFlavorVegetable oil

The invention relates to bread and a preparation method thereof, in particular to seafood and potato nutritional bread and a preparation method thereof. The seafood and potato nutritional bread is prepared from, by mass, 75-100 parts of mashed potato, 20-40 parts of minced seafood, 5-10 parts of algae powder, 1-2 parts of dried yeast, 0.1-0.5 part of glutamine transaminase, 2-5 parts of glucoamylase, 3-6 parts of vital gluten, 1-4 parts of table salt, 16-25 parts of white granulated sugar, 7-12 parts of vegetable oil, 5-10 parts of butter and 40-60 parts of water. The preparation method includes the steps of minced seafood preparation, yeast activation, dough making, proofing, forming, dough fermentation and roasting. The seafood and potato nutritional bread is unique in flavor, rich in nutrition and easy to prepare; the flavor and quality of the potato product are improved, so that the acceptance of consumers is improved, the consumption market of potatoes is expanded, and the national strategic deployment of using potatoes as staple food is further responded to.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Vitamin C microcapsule flour improver and preparation method thereof

ActiveCN101438721BImprove machinabilityImprove gas retention performanceDough treatmentPre-baking dough treatmentFlavorMonoglyceride

The invention relates to a vitamin C smicrocapsule flour improver and a preparation method thereof. The wall material of the flour improver is a mixed type wall material containing starch, stearic acid monoglyceride and hardened oil, and the bag core substance is vitamin C. The stearic acid monoglyceride and the hardened oil are mixed and then melted, then the starch and the vitamin C are added in the molten mass and evenly stirred to obtain the finished product by freezing, granulating and crushing. The smicrocapsule flour improver has the advantages of good stability, proper release rate, security, no foreign flavor and high utilization ratio of the vitamin C. In the method for preparing the vitamin C smicrocapsule flour improver, the realized cladding rate is up to 90 percent, no solvent is required to be used, the environmental pollution phenomenon does not exist, the process is simple and feasible and the cost is low.

Owner:中山市南方新元食品生物工程有限公司

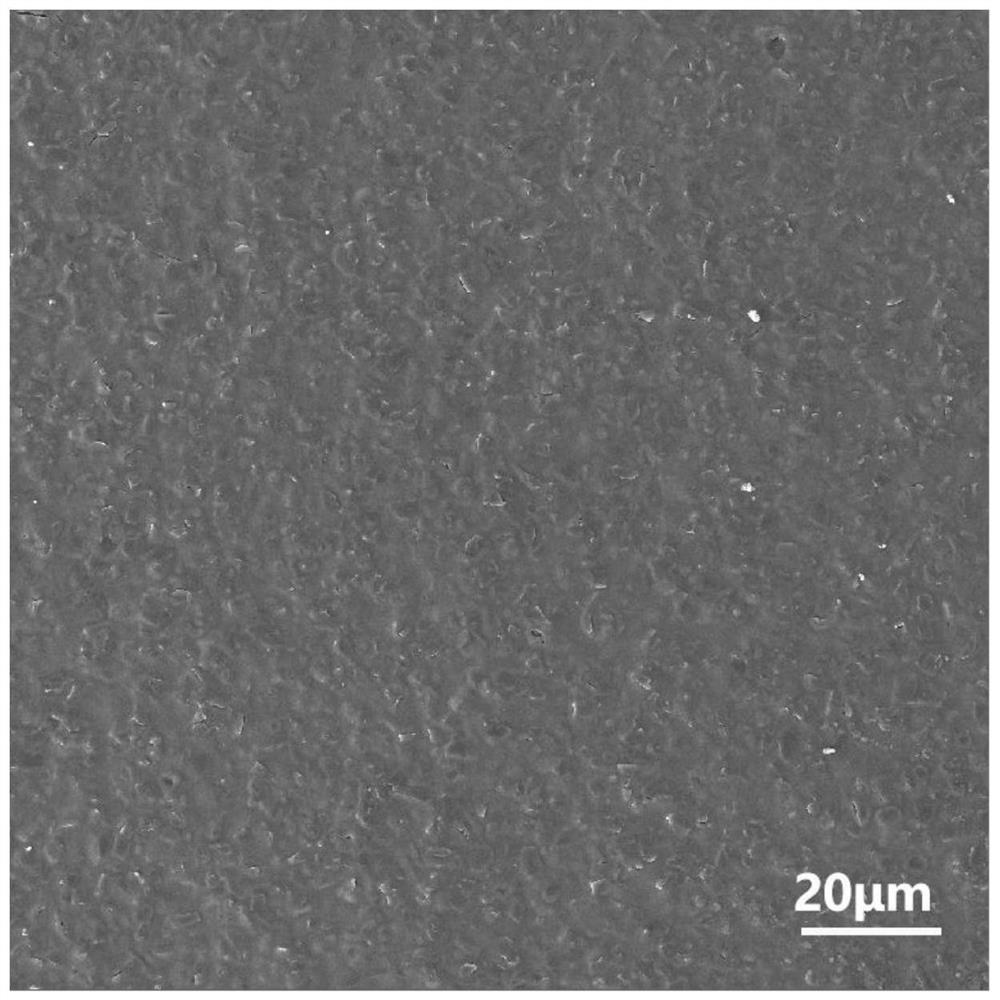

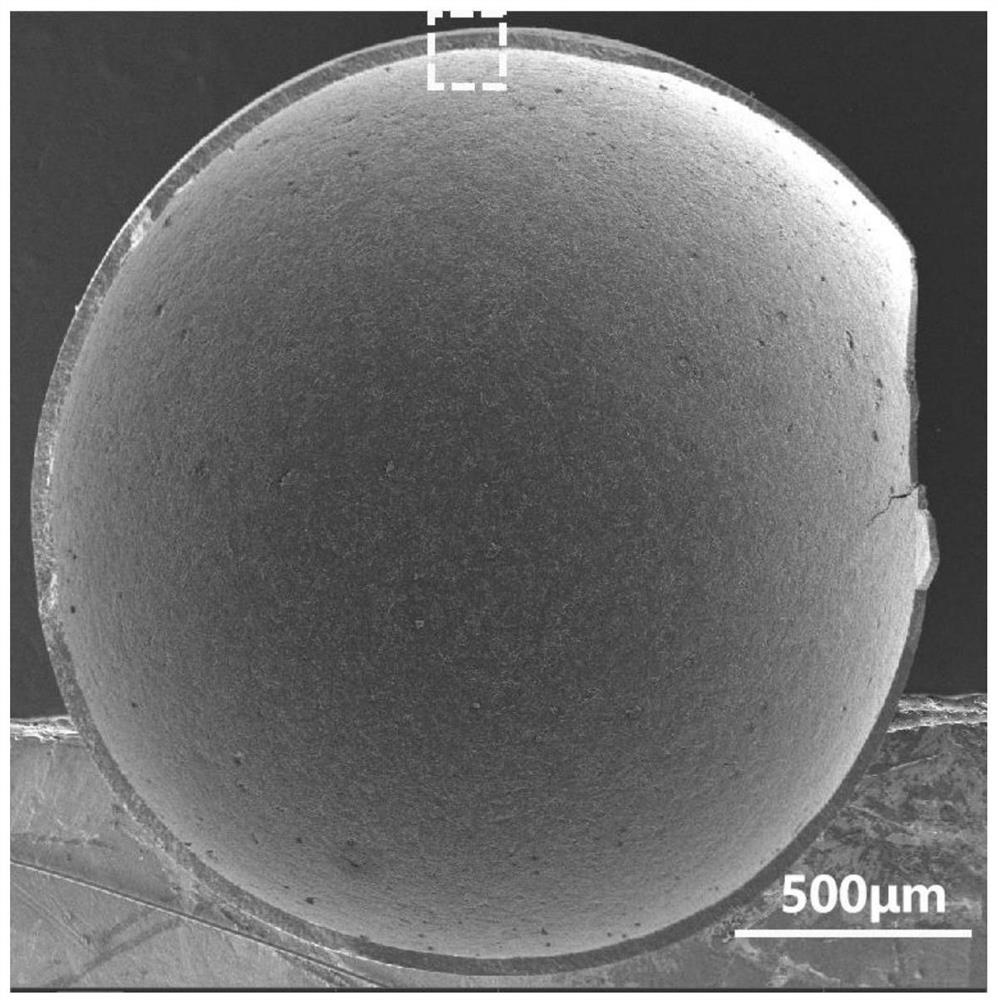

A kind of boron carbide/silicon carbide ceramic hollow microsphere and preparation method thereof

The invention discloses a boron carbide / silicon carbide ceramic hollow microsphere and a preparation method thereof. The preparation method utilizes a vinyl silane coupling agent to modify boron carbide, and then grafts PCS to B 4 on C‑V, then B 4 C-PCS is prepared into a slurry, and the polymer ball is used as a template to prepare a slurry coating ball, and finally the slurry on the polymer ball is cured in an air atmosphere, and then heat-treated in an air atmosphere to remove polymerization. Object spherical template, and finally fired at high temperature in an inert atmosphere to obtain boron carbide / silicon carbide ceramic hollow microspheres. The preparation method provided by the present invention can adjust the diameter of boron carbide / silicon carbide ceramic hollow microspheres by selecting polymer spheres with different diameters, and realize a wide range of diameter control, and the wall thickness of ceramic hollow microspheres can be changed by changing the slurry coating. The thickness of the wall can be adjusted in a wide range by adjusting the number of coating times. The preparation method is simple, convenient, fast and efficient, and the raw materials are cheap and easy to obtain, which has the potential for industrial production.

Owner:NAT UNIV OF DEFENSE TECH

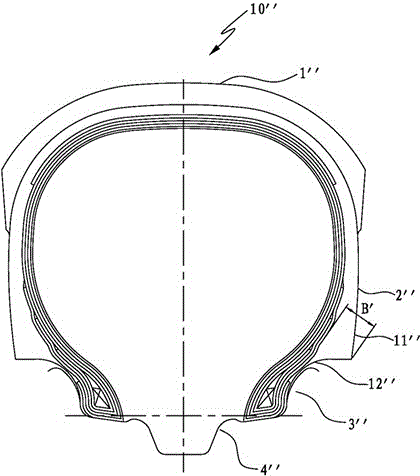

Section structure of motorcycle tire

InactiveCN106808929AReduce weightGuaranteed StrengthTyre sidewallsStress concentrationInternal pressure

Disclosed is a section structure of a motorcycle tire. The tire includes a tread part, sidewall parts, and bead parts. Each sidewall part is composed of an upper circle line and a lower straight line, wherein an obtuse angle is formed between the circle line and the straight line. Toothed lines are arranged on the straight lines in a full circumferential manner, and rounding is arranged between the sidewall parts and the bead parts. Circle lines and straight lines form the sidewall parts and make the sidewall parts be broken lines. Rigidity of the sidewall parts is ensured, so that the tire can well engage with a rim, and bead parts are protected from being separated from the rim. Further, toothed line design is added at straight lines of the sidewall parts, thereby reducing the weight of the whole tire. Rounding is arranged between the sidewall parts and the bead parts, so that stress concentration is prevented from generation between the sidewall parts and bead parts, and the strength of the bead parts is ensured. When the tire travels in a state of lower inner pressure, the tire can buckle the rim, and gas retention of the tire is improved for getting to the nearest maintenance point.

Owner:QINGDAO HUASHENG RUBBER

Inner tube rubber material with high performance on resisting cracks in break angles

The invention provides an inner tube rubber material with a high performance on resisting cracks in break angles. The rubber material comprises butyl rubber, ethylene propylene diene monomer, butyl reclaimed rubber, fast extrusion furnace black, general furnace black, white factice, 168 carbon black, microcrystalline wax, a chemical anti-aging agent AFS / LG, an active agent ZnO, an active agent SA,a processing aid D-S, tackifying resin 1102, processing oil P-150, a vulcanizing agent S-325, a promoter M, and an accelerant TMTD. A proper proportion of butyl rubber, butyl reclaimed rubber and ethylene propylene diene monomer is selected; and the white factice, the AFS / LG and the carbon black with proper specifications and proportions are added, so that excellent folding resistance and gas-retaining property are obtained, the resilience of the rubber material is remarkably improved, the ozone resistance, the weather resistance and the thermal aging resistance of the rubber material are improved, and the service life of the inner tube is prolonged.

Owner:KENDA RUBBER CHINA

A hot runner mold with double-layer runners

ActiveCN105965789BImprove gas retention performanceGood physical and mechanical propertiesDomestic articlesHollow articlesHot runnerTemperature control

The invention discloses a hot runner mold with double-layer runners, which includes a runner plate structure; the runner plate structure includes a transition plate and a cylinder plate; a first The surface layer flow channel plate and the first core layer flow channel plate; the inside of the first surface layer flow channel plate is provided with the first surface layer melt flow channel; the first core layer flow channel plate is provided with the first core layer melt material flow channel; A second surface layer flow channel plate and a second core layer flow channel plate are provided between the transition plate and the cylinder plate; a second surface layer molten material flow channel is provided in the second surface layer flow channel plate; the second core layer flow channel plate The channel plate is provided with a second core melt flow channel. The present invention adopts a double-layer flow channel design, that is, the surface melt flow channel is provided with a double-layer flow channel that can realize independent temperature control; the core layer melt flow channel is also provided with a double-layer flow channel that can realize independent temperature control, which can simultaneously Different molten plastics are injected into the cavity layer by layer, so that different materials can be injected layer by layer on the same preform.

Owner:GUANGZHOU HUAYAN PRECISION MACHINERY

Completely recoverable barrier PE membrane material as well as preparation method and application thereof

Owner:GUANGDONG FORETURE NEW MATERIAL CO LTD

A hot runner mold

ActiveCN106003570BImprove gas retention performanceGood physical and mechanical propertiesDomestic articlesHollow articlesHot runnerSurface layer

Owner:GUANGZHOU HUAYAN PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com