Rubber material for connecting butyl inner tube and inflating valve and preparation method thereof

A butyl inner tube and valve technology, which is applied in the field of tire production, can solve the problems of destroying the air tightness of the inner tube, affecting the service life and safety performance of the inner tube, cracks, etc., and achieve high bonding strength, improve air retention and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

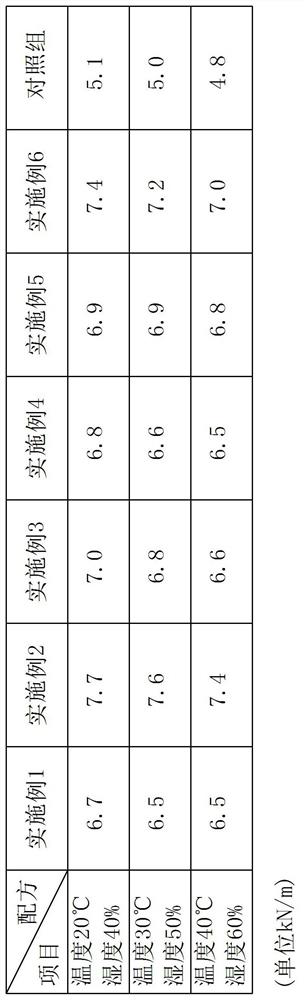

Examples

Embodiment 1

[0078] Embodiment 1: a kind of sizing material that connects butyl inner tube and valve, is made up of following components by weight:

[0079] Butyl rubber: 80 parts;

[0080] Soft carbon black: 30 parts;

[0081] Activator: 5 parts;

[0082] Petroleum resin: 5 parts;

[0083] Tackifying resin: 0.5 part;

[0084] White carbon black: 2 parts;

[0085] Coupling agent: 0.2 parts;

[0086] Accelerator: 0.5 parts;

[0087] Insoluble sulfur: 0.5 parts.

[0088] The activator adopts dihydrocarbyl zinc.

[0089] The coupling agent adopts long-chain alkyltrimethoxysilane.

[0090] The accelerator uses N,N-2 dicyclohexyl-2,2-dibenzothiazole sulfenamide.

[0091] A kind of preparation method that connects the sizing material of butyl inner tube and valve in embodiment 1, comprises the following steps:

[0092] S1, batching, carry out batching according to the formula of embodiment 1;

[0093] S2, internal mixing, butyl rubber, activator, petroleum resin, tackifying resin are ...

Embodiment 2

[0104] Embodiment 2: a kind of sizing material that connects butyl inner tube and valve, is made up of following components by weight:

[0105] Butyl rubber: 120 parts;

[0106] Soft carbon black: 80 parts;

[0107] Activator: 30 parts;

[0108] Petroleum resin: 35 parts;

[0109] Tackifying resin: 15 parts;

[0110] White carbon black: 22 parts;

[0111] Coupling agent: 3 parts;

[0112] Accelerator: 8 parts;

[0113] Insoluble sulfur: 6 parts.

[0114] The activator adopts dihydrocarbyl zinc.

[0115] The coupling agent adopts long-chain alkyltrimethoxysilane.

[0116] The accelerator uses N,N-2 dicyclohexyl-2,2-dibenzothiazole sulfenamide.

[0117] A kind of preparation method of the sizing material that connects butyl inner tube and valve in embodiment 2, comprises the following steps:

[0118] S1, batching, carry out batching according to the formula of embodiment 2;

[0119] S2, internal mixing, butyl rubber, activator, petroleum resin, tackifying resin are pu...

Embodiment 3

[0130] Embodiment 3: a kind of sizing material that connects butyl inner tube and valve, is made up of following components by weight:

[0131] Butyl rubber: 90 parts;

[0132] Soft carbon black: 40 parts;

[0133] Activator: 10 parts;

[0134] Petroleum resin: 10 parts;

[0135] Tackifying resin: 1 part;

[0136] White carbon black: 5 parts;

[0137] Coupling agent: 0.5 parts;

[0138] Accelerator: 1.5 parts;

[0139] Insoluble sulfur: 1 part.

[0140] The activator adopts dihydrocarbyl zinc.

[0141] The coupling agent adopts long-chain alkyltrimethoxysilane.

[0142] The accelerator uses N,N-2 dicyclohexyl-2,2-dibenzothiazole sulfenamide.

[0143] A kind of preparation method of the sizing material that connects butyl inner tube and valve in embodiment 3, comprises the following steps:

[0144] S1, batching, carry out batching according to the formula of embodiment 3;

[0145] S2, internal mixing, butyl rubber, activator, petroleum resin, tackifying resin are put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com