Hot runner mold

A technology of hot runners and runners, which is applied in household appliances, other household appliances, household components, etc., can solve the problems of poor mechanical and physical properties of products, poor toughness, and increased processing difficulty, so as to improve mechanical and physical properties and improve durability. Gas performance, changing the effect of light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

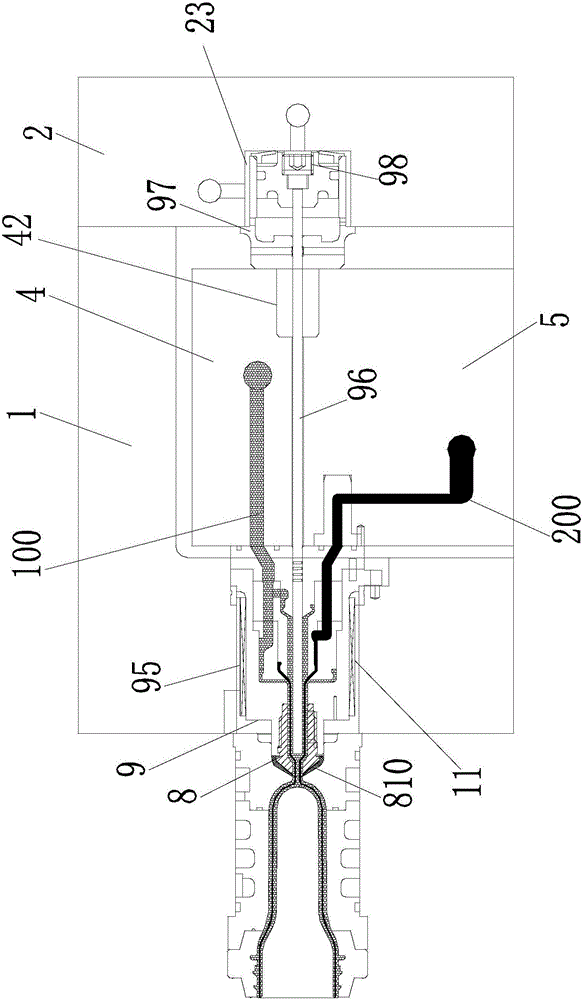

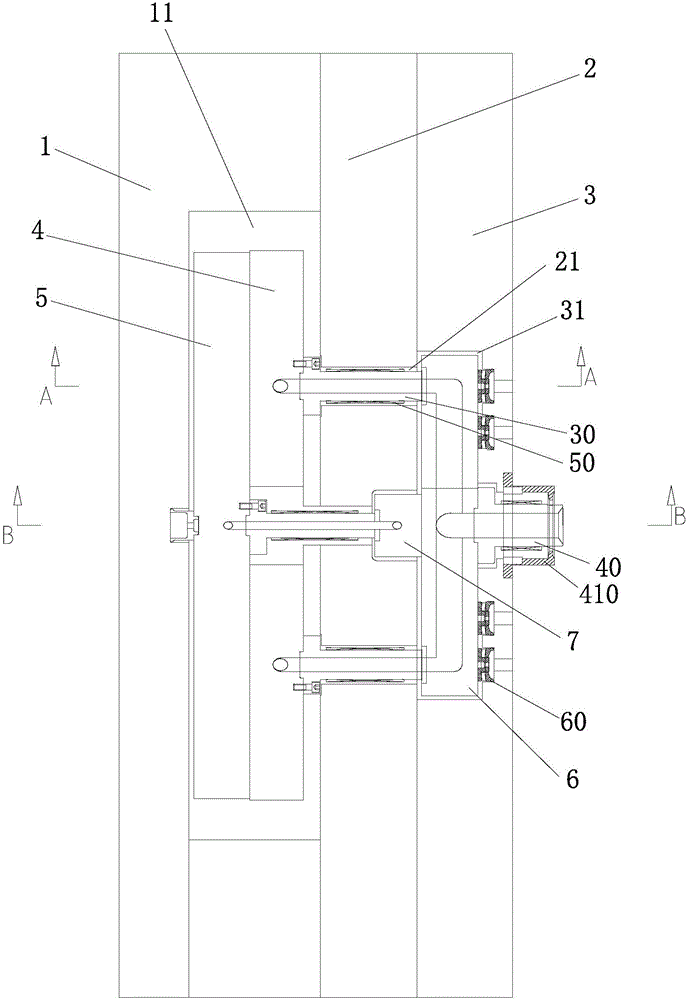

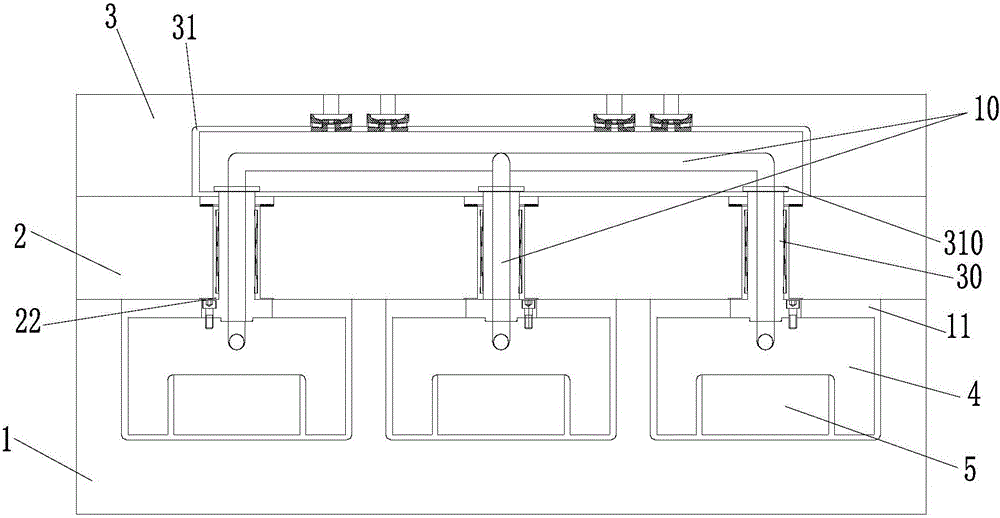

[0052] refer to Figure 1-5 , this embodiment provides a hot runner mold, including a runner plate structure and a nozzle structure;

[0053] The inside of the runner plate structure is provided with a surface melt flow channel and a core layer melt flow channel; the surface melt flow channel has a first glue inlet for introducing the surface melt material and a second glue inlet for discharging the surface layer melt material. A glue outlet; the core layer melt flow channel has a second glue inlet for introducing the core layer melt and a second glue outlet for discharging the core layer melt; the inside of the flow channel plate structure is also provided There are nozzle mounting holes;

[0054] The nozzle structure includes an injection nozzle 8 and a base 9; the injection nozzle 8 includes a cylindrical injection nozzle body, the injection nozzle body has an inlet 81 for introducing molten material and an outlet 82 for discharging molten material, The inlet is at one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com