Inner tube rubber material with high performance on resisting cracks in break angles

A folding-resistant and inner tube technology, applied in the rubber field, can solve the problems of cracking at the corners, affecting the air retention and service life of the inner tube, and achieve the effect of improving air retention, excellent air retention performance, and weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of inner tube rubber compound with high resistance to knuckle cracking. The raw material components are: 80 parts of butyl rubber, 15 parts of EPDM rubber, 10 parts of butyl reclaimed rubber, 30 parts of quick-press furnace black, and 35 parts of general-purpose furnace black , 5 parts of white ointment, 7 parts of 168 carbon black, 1 part of microcrystalline wax, 0.3 parts of chemical antioxidant AFS / LG, 5.9 parts of active agent (5 parts of ZnO, 0.9 part of SA), 0.5 part of processing aid D-S (ie N-(2-hydroxyethyl)stearamide, CAS: 111-57-9), 5.4 parts of tackifier 1102, 21 parts of processing oil P-150, 1.8 parts of vulcanizing agent S-325, 2 parts of accelerator ( 0.5 parts of M, 1.5 parts of TMTD).

[0030] Preparation process: (this process is carried out in a 255L internal mixer)

[0031] Step 1: Put in raw materials such as butyl rubber, butyl reclaimed rubber, EPDM rubber, carbon black, old anti-corrosion agent, active agent, white ointment, processing o...

Embodiment 2

[0039] A kind of inner tube rubber compound with high resistance to knuckle cracking. The raw material components are: 77 parts of butyl rubber, 17 parts of EPDM rubber, 12 parts of butyl reclaimed rubber, 25 parts of quick-press furnace black, and 40 parts of general-purpose furnace black , 5 parts of white ointment, 8 parts of 168 carbon black, 1.5 parts of microcrystalline wax, 0.3 parts of chemical antioxidant AFS / LG, 5.4 parts of active agent (4.5 parts of ZnO, 0.9 parts of SA), 0.5 parts of processing aid D-S, 8.0 parts Parts of tackifier 1102, 18 parts of processing oil P-150, 1.8 parts of vulcanizing agent S-325, 2 parts of accelerator (0.5 parts of M, 1.5 parts of TMTD).

[0040] Preparation process: (this process is carried out in a 255L internal mixer)

[0041] Step 1: Put in raw materials such as butyl rubber, butyl reclaimed rubber, EPDM rubber, carbon black, anti-corrosion agent, active agent, white ointment, processing oil and other raw materials and mix for 230...

Embodiment 3

[0049] A kind of inner tube rubber compound with high resistance to knuckle cracking. The raw material components are: 83 parts of butyl rubber, 12 parts of EPDM rubber, 10 parts of butyl reclaimed rubber, 35 parts of quick-press furnace black, and 30 parts of general-purpose furnace black , 5 parts of white ointment, 9 parts of 168 carbon black, 1.5 parts of microcrystalline wax, 0.2 parts of chemical antioxidant AFS / LG, 5 parts of active agent (4 parts of ZnO, 1 part of SA), 1.0 part of processing aid D-S, 4 parts Parts of tackifier 1102, 22 parts of processing oil P-150, 1.8 parts of vulcanizing agent S-325, 2 parts of accelerator (0.5 parts of M, 1.5 parts of TMTD).

[0050] The preparation process is the same as before.

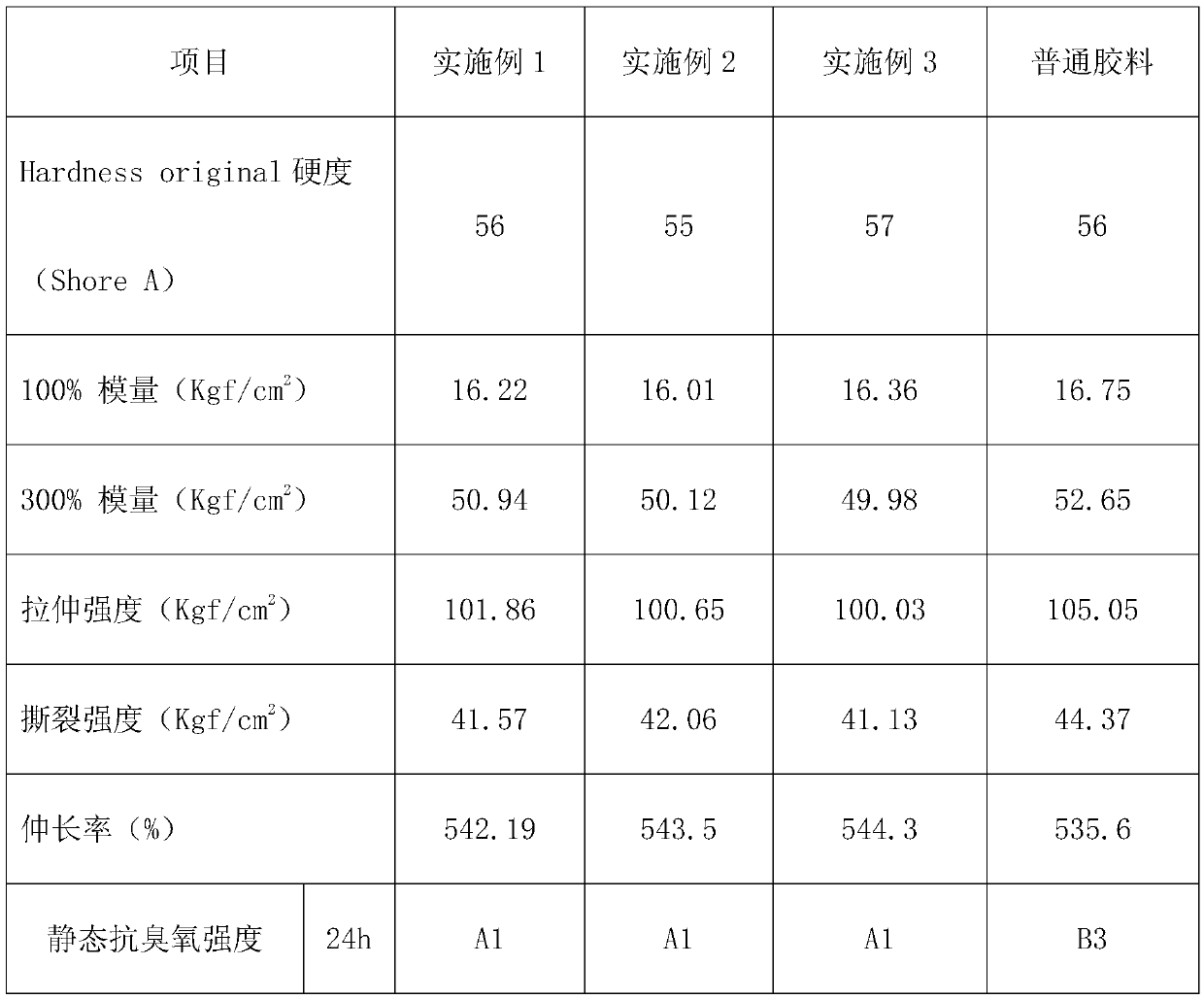

[0051] The technical indicators of the products prepared by the embodiments are shown in the table below.

[0052]

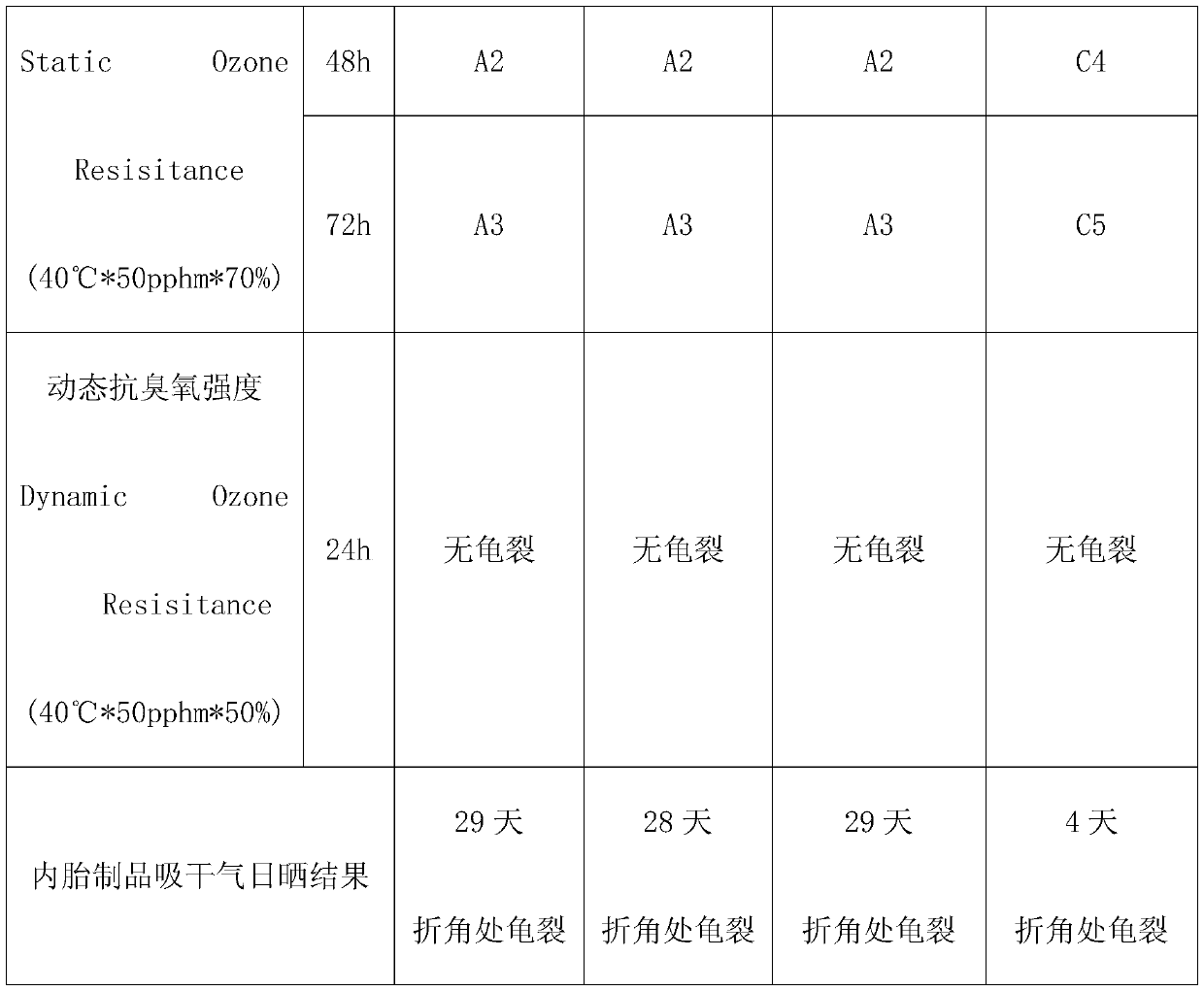

[0053]

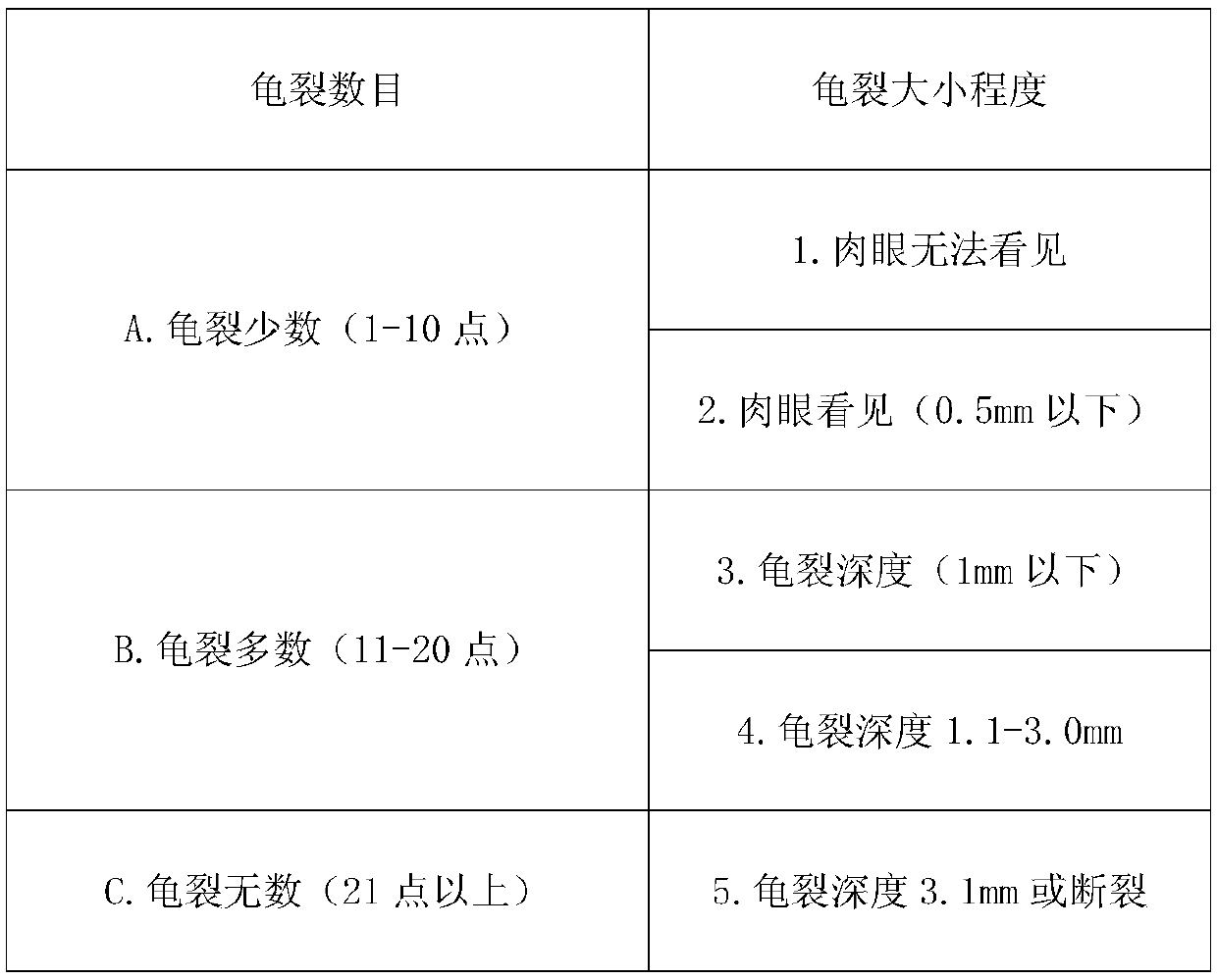

[0054] Note: The description of crack judgment is as follows

[0055]

[0056] From the above main technical indicato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com