A hot runner mold with double-layer runners

A technology of hot runner and double-layer flow, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of material brittleness, poor toughness, and poor mechanical and physical properties of products, so as to achieve good toughness and improve gas retention Performance, the effect of improving mechanical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

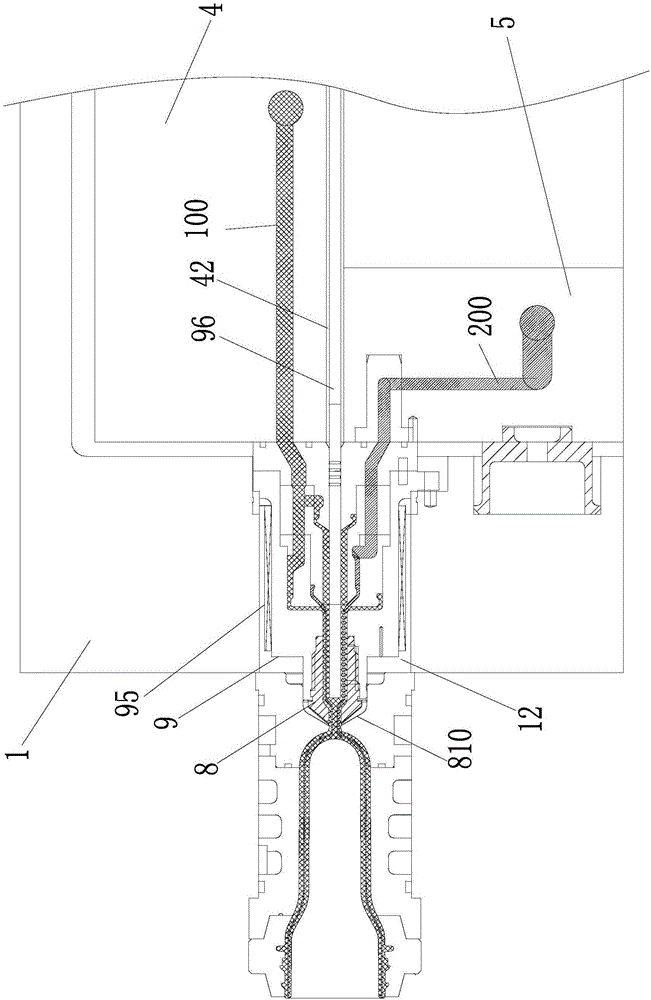

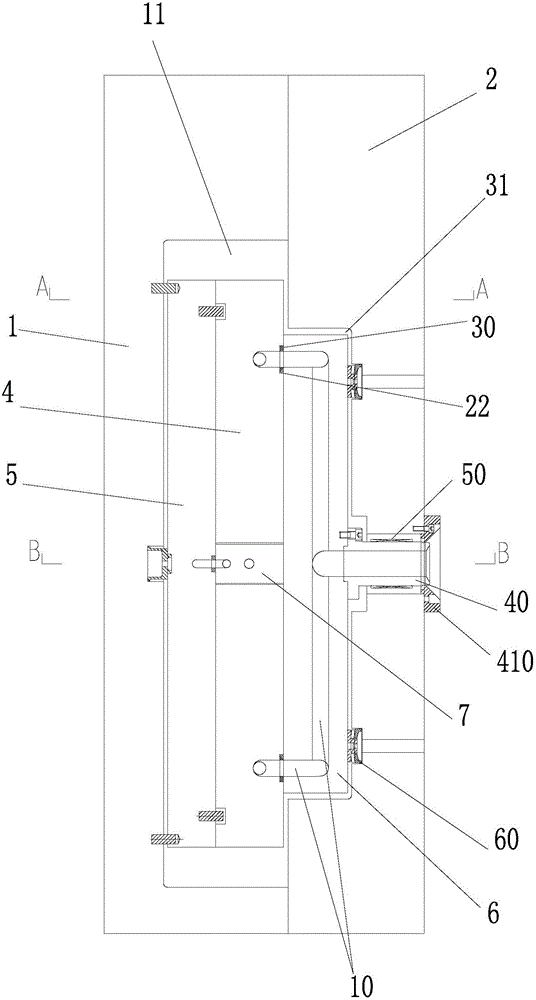

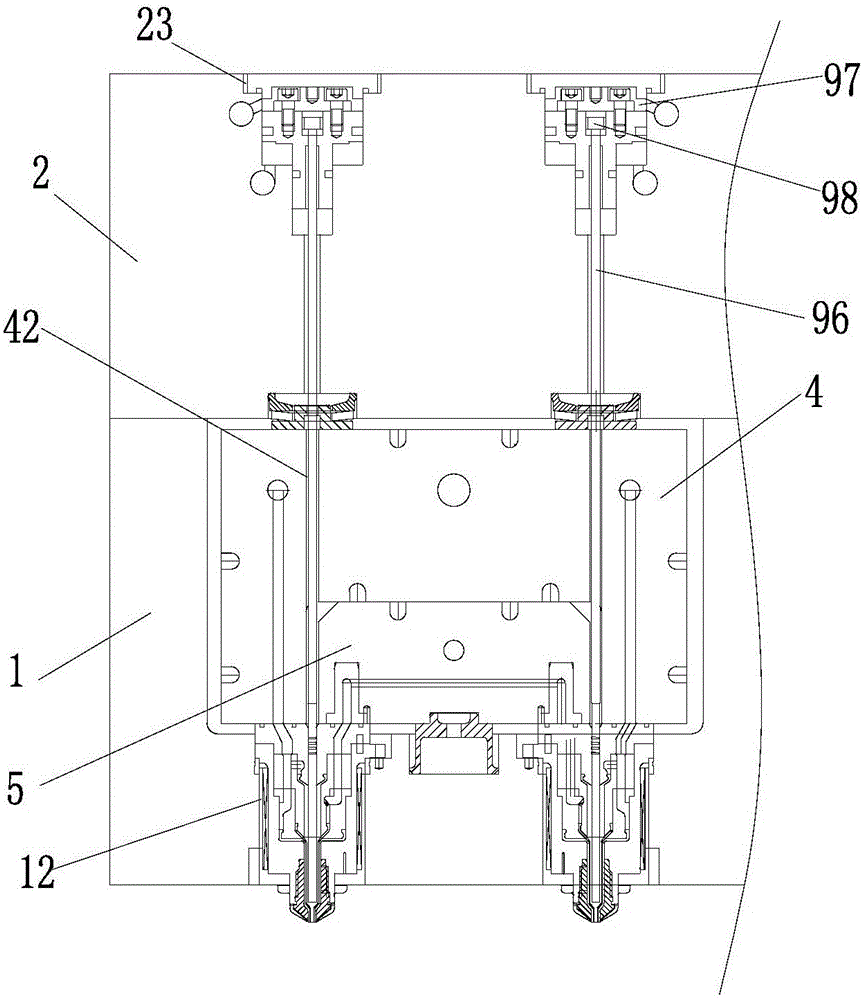

[0047] refer to Figure 1-6 , this embodiment provides a hot runner mold with double-layer runners, including a runner plate structure and a nozzle structure;

[0048] The inside of the runner plate structure is provided with a surface melt flow channel and a core layer melt flow channel; the surface melt flow channel has a first glue inlet for introducing the surface melt material and a second glue inlet for discharging the surface layer melt material. A glue outlet; the core layer melt flow channel has a second glue inlet for introducing the core layer melt and a second glue outlet for discharging the core layer melt; the inside of the flow channel plate structure is also provided There are nozzle mounting holes; the flow channel plate structure includes a transition plate 1 and a cylinder plate 2; one end of the cylinder plate 2 is fixedly connected to the transition plate 1;

[0049] At least one first accommodation cavity is provided between the transition plate 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com