A kind of boron carbide/silicon carbide ceramic hollow microsphere and preparation method thereof

A technology of silicon carbide ceramics and hollow microspheres, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problems of high cost, high preparation difficulty, poor controllability, etc., and achieves high density and simple and convenient preparation method. , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention provides a method for preparing boron carbide / silicon carbide ceramic hollow microspheres, comprising:

[0025] S1: Disperse the boron carbide powder in an ethanol aqueous solution containing a vinyl silane coupling agent, adjust it to acidity with glacial acetic acid, stir at room temperature to fully hydrolyze the vinyl silane coupling agent, stand for stratification, and separate the solid phase Filter and wash with ethanol, dry, grind and sieve to obtain vinyl-modified boron carbide powder;

[0026] S2: Disperse the vinyl-modified boron carbide powder in a benzene solution of PCS, heat up to 50-80° C., add a platinum-containing catalyst, and react at a constant temperature for 12-36 hours, then filter, and the obtained solid phase is subjected to benzene-based solution. After flux washing, dry grinding and sieving to obtain PCS-grafted boron carbide powder;

[0027] S3: take the PCS-grafted boron carbide powder as a solid phase, take PCS (poly...

Embodiment 1

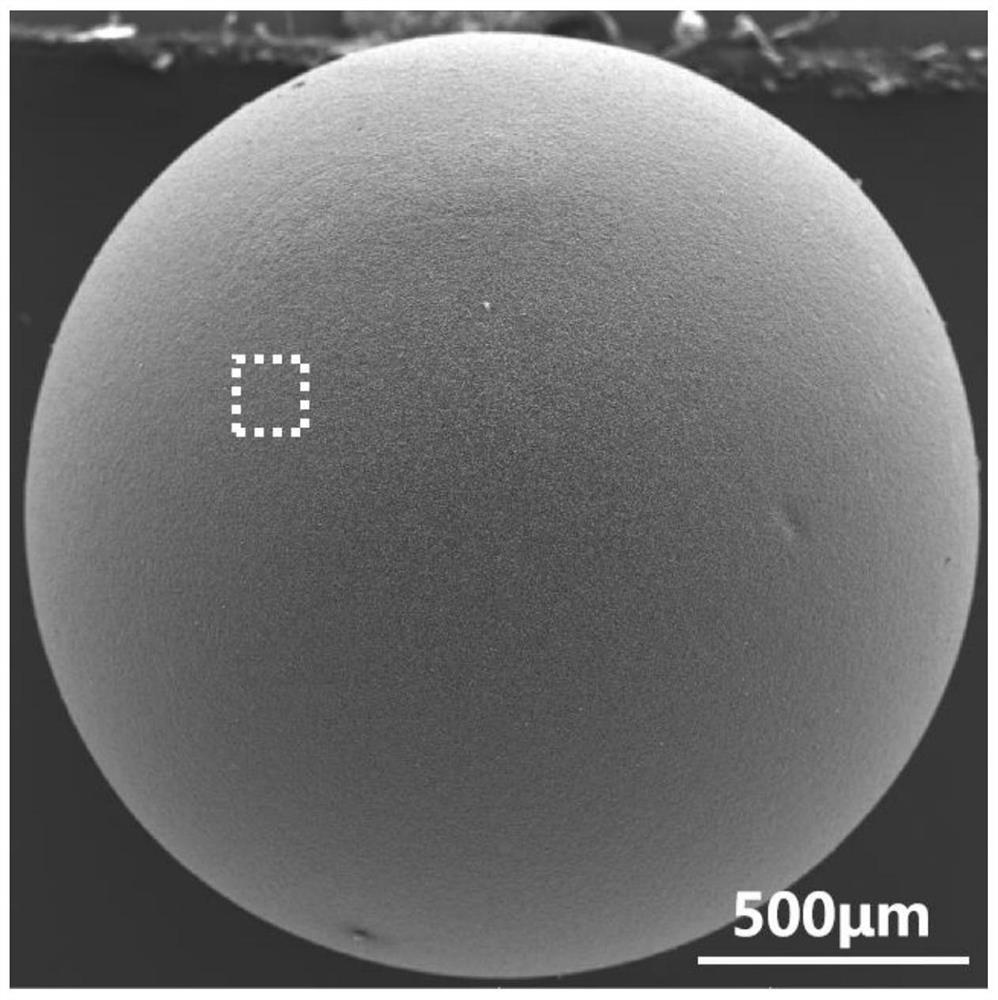

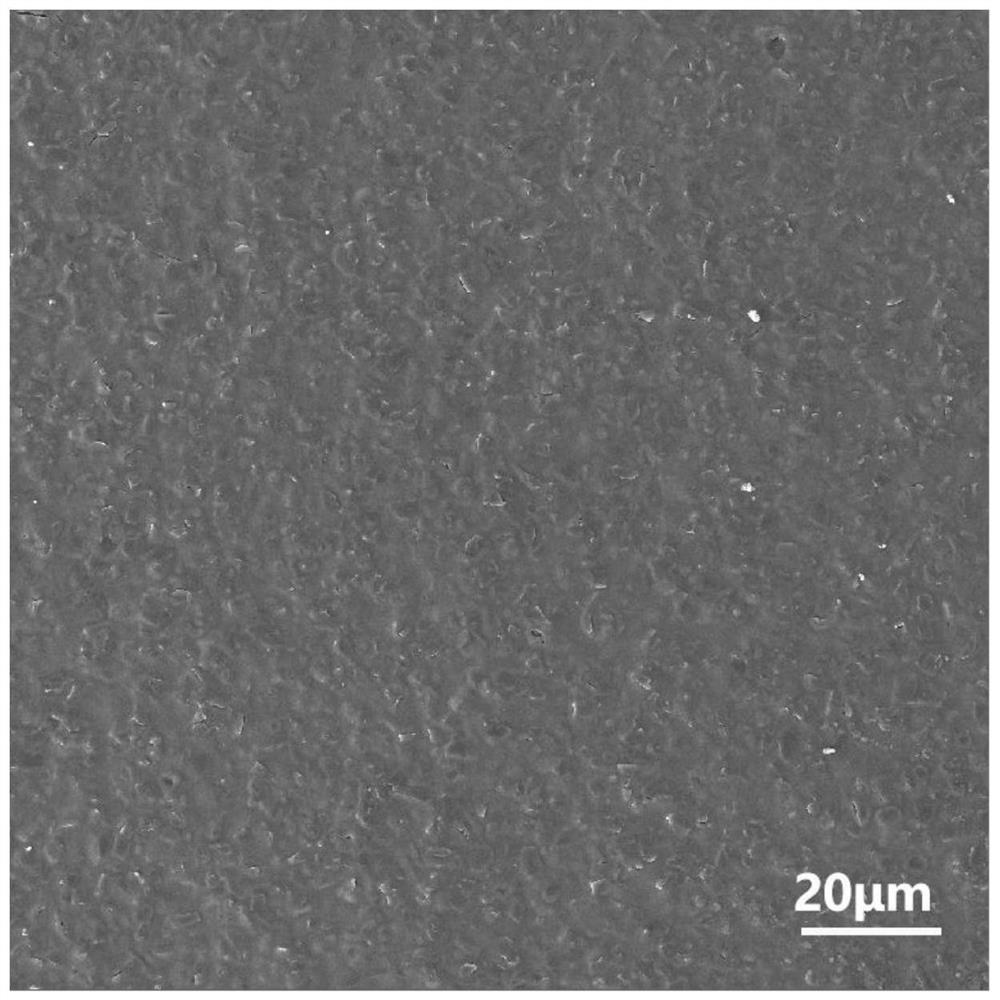

[0075] This embodiment provides a boron carbide / silicon carbide ceramic hollow microsphere with a diameter of about 1.7 mm and a wall thickness of about 30-40 μm.

[0076] This embodiment also provides a method for preparing boron carbide / silicon carbide ceramic hollow microspheres as described above, comprising the following steps:

[0077] The first step, vinyl modification of boron carbide powder:

[0078] 1. Disperse 20 grams of micron-grade high-purity boron carbide powder (particle size 1-3 microns) in 50 ml of 50vt% ethanol deionized aqueous solution, stir magnetically for 30 minutes, and then ultrasonically disperse for 30 minutes.

[0079] 2. Add 9 ml of trimethoxyvinylsilane, stir magnetically for 30 minutes, and then ultrasonically disperse for 30 minutes.

[0080] 3. Under the condition of magnetic stirring, add glacial acetic acid dropwise to the mixture until the pH value of the mixture reaches 2-4, and keep stirring at room temperature for 20h.

[0081] 4. Ful...

Embodiment 2

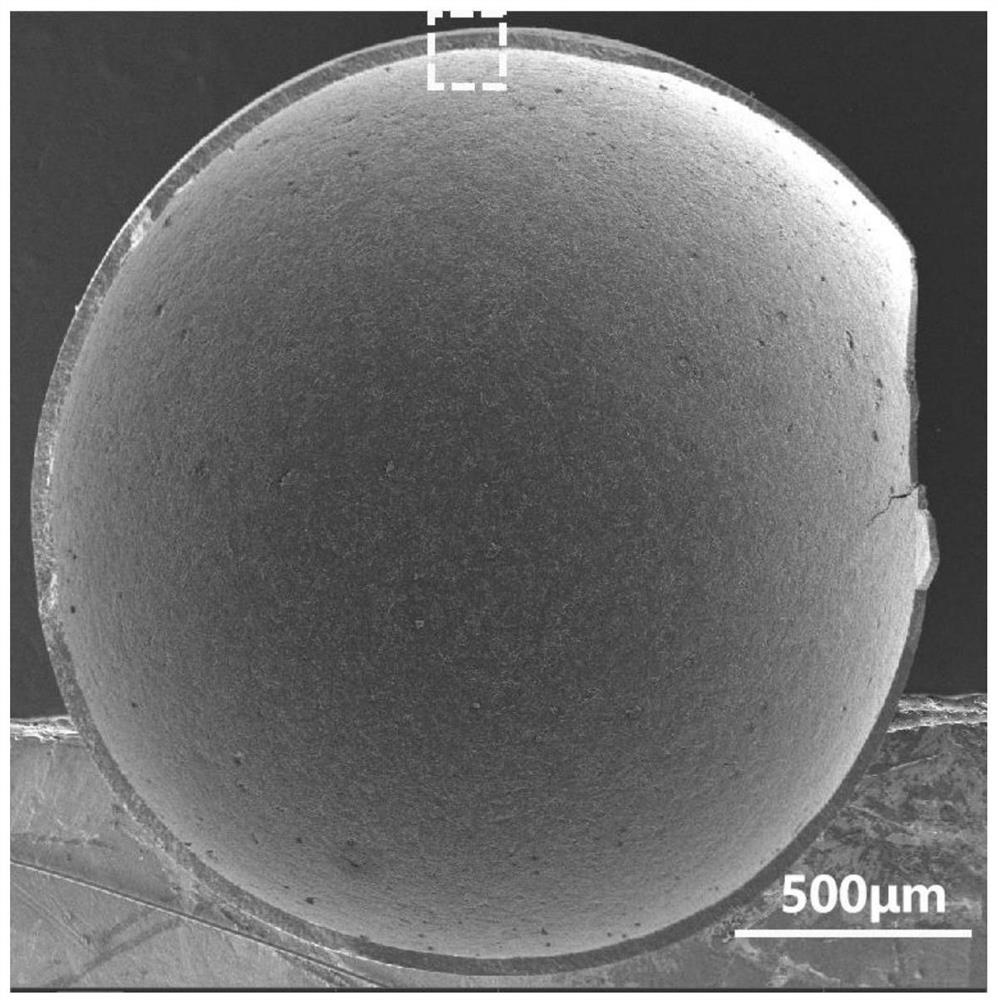

[0101] This embodiment provides a boron carbide / silicon carbide ceramic hollow microsphere with a diameter of about 2.1-2.2 mm and a wall thickness of about 60-120 μm.

[0102] This embodiment also provides a method for preparing boron carbide / silicon carbide ceramic hollow microspheres as described above, comprising the following steps:

[0103] The first step, vinyl modification of boron carbide powder: same as Example 1.

[0104] The second step, polycarbosilane graft modification of boron carbide powder: same as Example 1.

[0105] The third step, the preparation of modified boron carbide powder slurry:

[0106] 1. Take 1.5 grams of B 4 C-PCS, 3 mL xylene, 0.4 g PCS (softening point 230°C) in a small glass vial.

[0107] 2. Magnetic stirring for 30 minutes, and then ultrasonically dispersing for 30 minutes, keep stirring continuously at a stirring rate of 400 r / min to obtain boron carbide powder slurry (B 4 C-P0.4 slurry).

[0108] The fourth step, coating the modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com