Polyamide-polyesteramide thermosol and its preparing process

A hot-melt adhesive and polyamide technology, applied in the direction of adhesives, etc., can solve the problems of unsatisfactory peel strength and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

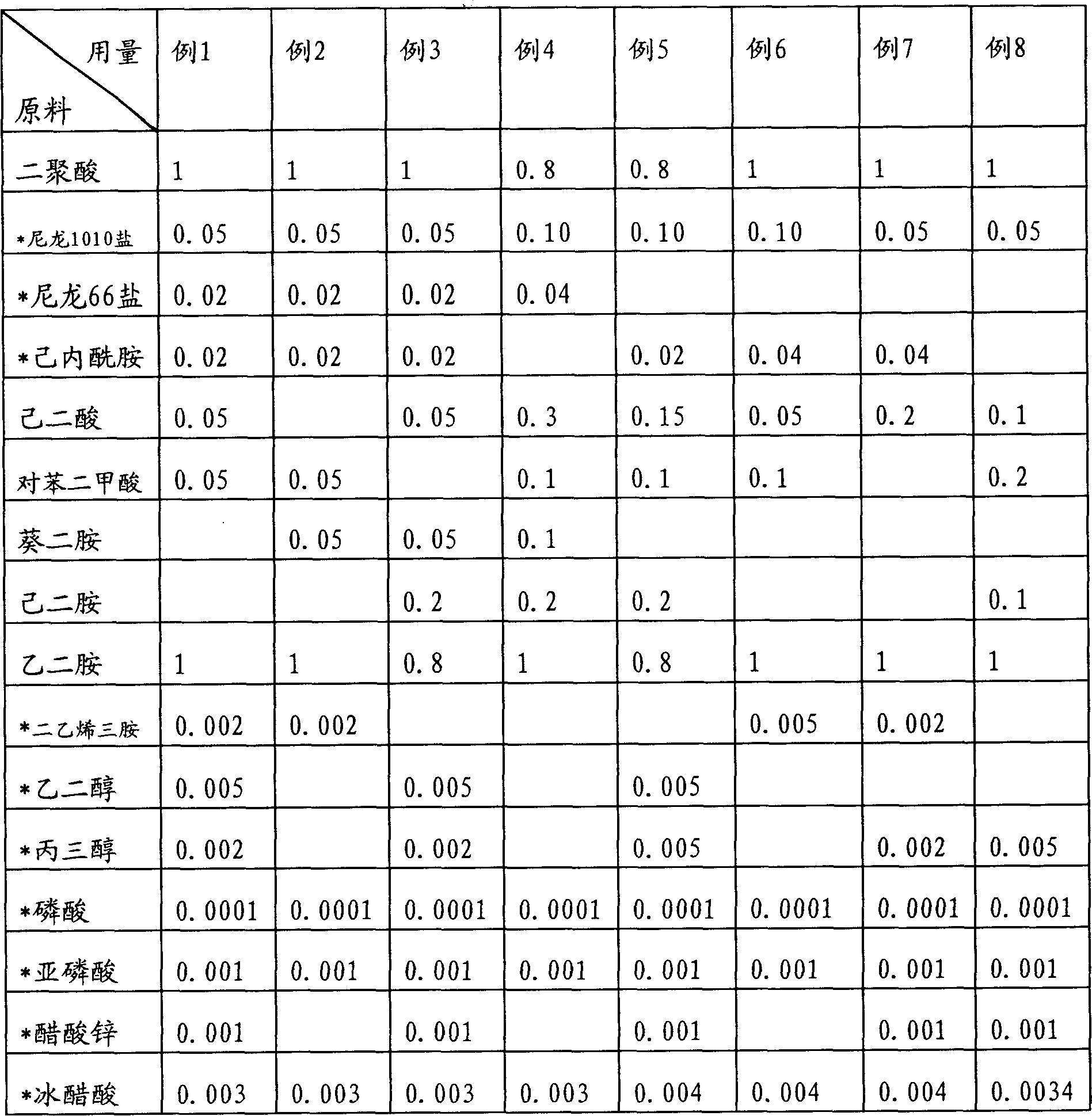

Examples

Embodiment 1

[0038] Reaction material: base material dimer acid ratio of main material: 1 mol,

[0039] Adipic acid ratio: 0.05 mol,

[0040] Terephthalic acid ratio: 0.05 mol,

[0041] Main ingredient ethylenediamine ratio: 1 mol,

[0042] Modifier: The proportion of nylon 1010 salt is 5% of the weight of the reaction material,

[0043] Nylon 66 salt proportioning is 20% of reaction material weight,

[0044] Caprolactam proportioning is 2% of reaction material weight,

[0045] Chain extender: The proportion of ethylene glycol is 0.5% of the weight of the reaction material,

[0046] Glycerol proportioning is 0.2% of reaction material weight,

[0047] Cross-linking agent: The ratio of diethylenetriamine is 0.2% of the weight of the reaction material,

[0048] Catalyst: the ratio of phosphoric acid is 0.01% of the total weight of the above reaction materials,

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com