Novel tire airtight liner promoter and preparation method and application thereof

An air liner and enhancer technology, used in special tires, tire parts, building components, etc., can solve the problems of no improvement in gas permeability, poor processing fluidity of rubber, and narrow range of rubber types, so as to improve gas retention. Improved performance and driving safety, improved air retention, reduced surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

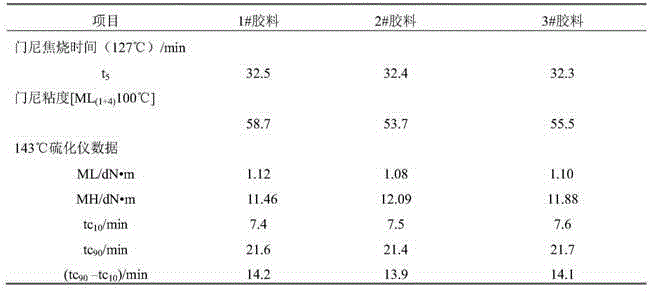

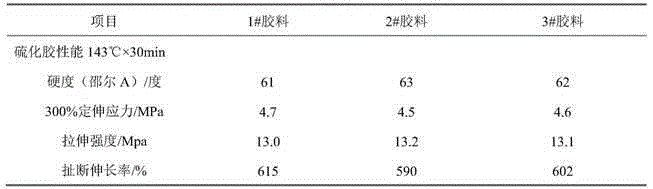

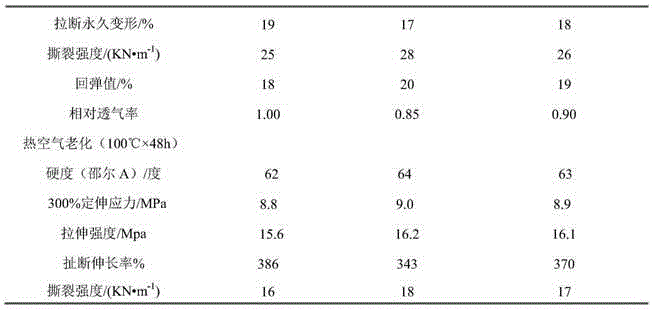

Examples

Embodiment 1

[0044] Weigh raw materials according to the following composition, and prepare 100 grams of airtight layer promoter of the present invention

[0045]

[0046] The preparation steps are as follows:

[0047] Melt rosin resin, refined pitch resin, C9 petroleum resin, styrene-modified phenolic resin and zinc oleate at 145°C, then slowly add fly ash while stirring, and continue stirring for 15 minutes after adding fly ash. Finally pour out and cool to obtain the novel tire inner-layer promoter.

Embodiment 2

[0049] Weigh raw materials according to the following composition, and prepare 100 grams of airtight layer promoter of the present invention

[0050]

[0051] The preparation method is the same as in Example 1.

Embodiment 3

[0053] Weigh raw materials according to the following composition, and prepare 100 grams of airtight layer promoter of the present invention

[0054]

[0055] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com