Gluten-free grain fermentation type flour product and preparation method thereof

A fermented, gluten-free technology, applied in the direction of bacteria used in food preparation, food science, lactobacillus, etc., can solve the problem of not being able to form fermented steamed noodle products, and achieve increased elasticity, stable fermentation, and fine texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing the fermented noodle product described in the above scheme, comprising the steps of:

[0035] 1) activating after mixing yeast powder, plant lactobacillus powder and water, to obtain a fermented liquid;

[0036] 2) adding TG enzyme, gluten-free grain powder, vegetable protein powder without gluten protein, salt and bread improver in sequence to the fermented liquid in the step 1) and then stirring to obtain kneaded dough;

[0037] 3) Fermenting the kneaded dough in step 2) at 28-30°C for 1.5-2 hours, then fermenting at 38-40°C for 30-60 minutes, and then fermenting at 48-52°C for 20-30 minutes to obtain fermented dough;

[0038] 4) rolling the fermented dough of the step 3) to obtain pressed dough;

[0039] 5) Dividing the pressed noodle sheet in step 4), kneading and molding the obtained division pieces, then performing proofing and steaming in sequence to obtain fermented noodle products.

[0040] In the invention, yeast p...

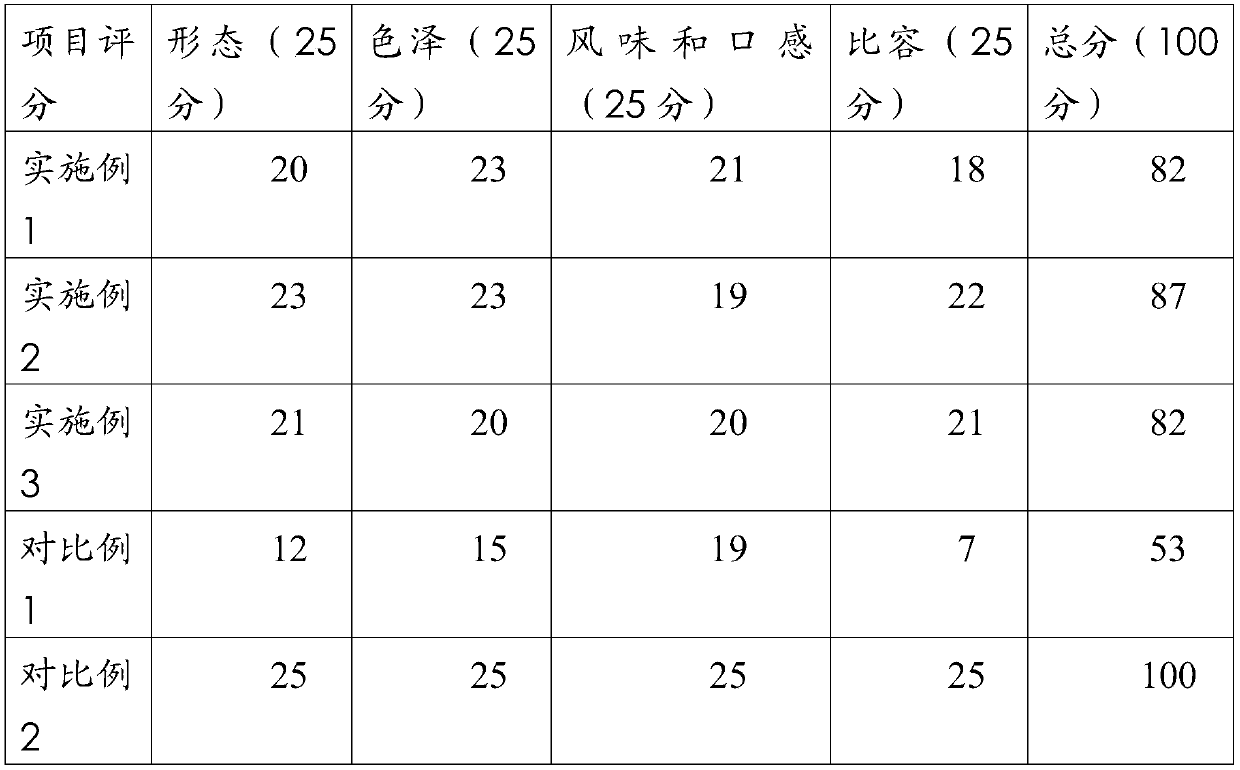

Embodiment 1

[0047] Weigh 1.0Kg of corn flour, 0.2Kg of soybean flour, 100g of yeast powder, 50g of TG enzyme, 10g of plant lactobacillus powder, 30g of salt, 10g of bread improver and 800g of water.

[0048] 1) After heating water to 35°C, mix and activate yeast powder, plant Lactobacillus powder and water for 18 minutes to obtain a fermentation broth;

[0049] 2) Add TG enzyme, gluten-free grain flour, corn flour, salt and bread improver to the fermented liquid in the step 1) sequentially, and stir at a speed of 30 r / min for 15 minutes to obtain kneaded dough;

[0050] 3) Fermenting the kneaded dough in step 2) at 28°C for 2 hours, then fermenting at 38°C for 60 minutes, and then fermenting at 48°C for 30 minutes to obtain fermented dough;

[0051] 4) The fermented dough in the step 3) is rolled by a tablet press (the distance between the upper and lower rollers is 0.4cm) for 12 times to obtain pressed dough sheets;

[0052] 5) After dividing the pressed dough sheet in step 4), knead th...

Embodiment 2

[0054] Weigh 1.2Kg of rice flour, 0.1Kg of soybean protein powder, 300g of yeast powder, 1g of TG enzyme, 50g of plant lactobacillus powder, 10g of salt, 20g of bread improver and 600g of water.

[0055] 1) After heating water to 40°C, mix and activate yeast powder, plant Lactobacillus powder and water for 12 minutes to obtain a fermentation broth;

[0056] 2) Add TG enzyme, gluten-free grain flour, corn flour, salt and bread improver to the fermented liquid in step 1) and stir at a speed of 50 r / min for 10 minutes to obtain kneaded dough;

[0057] 3) Fermenting the kneaded dough in step 2) at 30°C for 1.5 hours, then fermenting at 40°C for 30 minutes, and then fermenting at 52°C for 20 minutes to obtain fermented dough;

[0058] 4) The fermented dough in the step 3) is rolled by a tablet press (the distance between the upper and lower rollers is 0.6cm) for 8 times to obtain pressed dough;

[0059] 5) After dividing the pressed dough sheet in step 4), knead the obtained divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com