Gluten-free cereal cakes and making method thereof

A gluten-free and grain-free technology, applied in food science, baked food, baking, etc., can solve problems such as poor taste and flavor of cakes, lack of viscoelasticity, etc., and achieve the effect of increasing viscoelasticity, rich nutrition, and improving texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

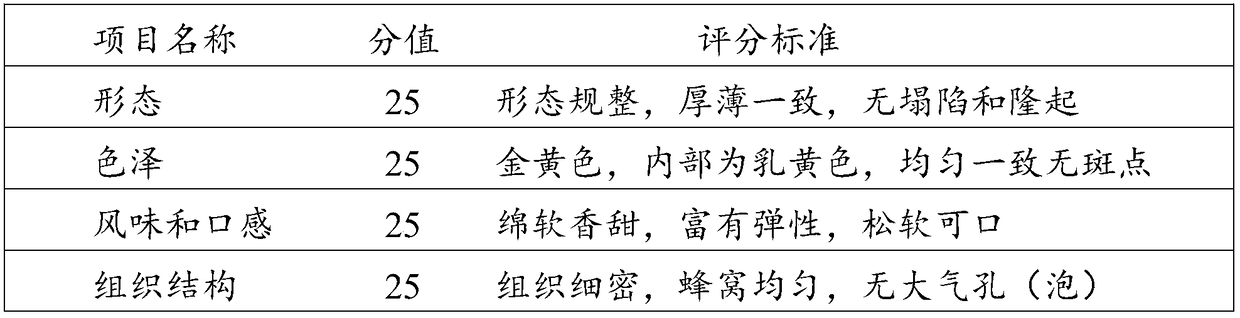

Examples

preparation example Construction

[0042] The present invention also provides a preparation method of the gluten-free cereal cake described in the above technical scheme, which includes the following steps:

[0043] (1) Mixing the gluten-free cereals, soybeans, transglutaminase, yeast, lactobacillus and NaCl described in the above technical scheme to obtain a batter;

[0044] (2) subjecting the batter obtained in the step (1) to the first fermentation to obtain a first fermentation product; the temperature of the first fermentation is 26-32°C, and the time of the first fermentation is 1.0-2.5h;

[0045] (3) The first fermented product obtained in step (2) is subjected to second fermentation to obtain a second fermented product; the temperature of the second fermentation is 38-44°C, and the time of the second fermentation is 1.5- 3.0h;

[0046] (4) The second fermentation product obtained in the step (3) is subjected to the third fermentation to obtain the third fermentation product; the temperature of the third ferment...

Embodiment 1

[0063] The raw materials and dosage for making the cake: 2.5kg of corn flour, 2.5kg of eggs, 2.5kg of white sugar, 0.5kg of soybean meal, 0.5kg of vegetable oil, 0.01kg of transglutaminase, and 0.01kg of Lactobacillus plantarum powder through a 100 mesh sieve. Dry yeast powder 0.05kg, baking powder 0.01kg, salt 0.01kg and drinking water 0.1kg.

[0064] Production Method:

[0065] After the above corn flour and soybean flour are thoroughly mixed, the drinking water which has been dissolved with TG enzyme, yeast, lactobacillus plantarum and salt is added and mixed thoroughly to prepare a batter.

[0066] Place the above-mentioned mixed batter in a thermostat for staged fermentation, and incubate at 28°C for 2 hours to obtain the first fermentation product; incubate the first fermentation product at 40°C for 2.5 hours to obtain the second fermentation product; The fermented product was incubated at 50°C for 30 minutes to obtain the third fermented product, which was taken out and coole...

Embodiment 2

[0071] The raw materials and dosage for making the cake: 4.5kg of corn flour, 4.5kg of eggs, 4.5kg of white sugar, 3.0kg of soybean meal, 1.5kg of vegetable oil, 0.1kg of transglutaminase, 0.2kg of Lactobacillus plantarum powder through a 100 mesh sieve. 0.2kg of dry yeast powder, 0.05kg of baking powder, 0.25kg of salt and 0.9kg of drinking water.

[0072] Production Method:

[0073] After mixing the corn flour and soybean flour, the drinking water which has been dissolved with TG enzyme, yeast, Lactobacillus plantarum and salt is added and mixed thoroughly to prepare a batter.

[0074] Place the above-mentioned mixed batter in a thermostat for staged fermentation, cultivate at 30°C for 1.5 hours to obtain the first fermented product; incubate the first fermented product at 42°C for 2 hours to obtain the second fermented product; The fermented product was incubated at 55°C for 20 minutes to obtain the third fermented product, which was taken out and cooled to room temperature.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com