High-gas-maintaining-performance inner surface rubber and synthesis method of high-gas-maintaining-performance inner surface rubber

A gas-retaining, inner surface adhesive technology, applied in the direction of natural rubber adhesives, non-polymer adhesive additives, adhesives, etc., can solve the low cost of low-halogenated butyl rubber technology, poor processing dispersion of halogenated butyl rubber, Problems such as the decrease of rubber vulcanization adhesion, etc., to achieve good aging resistance physical properties, good glue workability, and improved physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

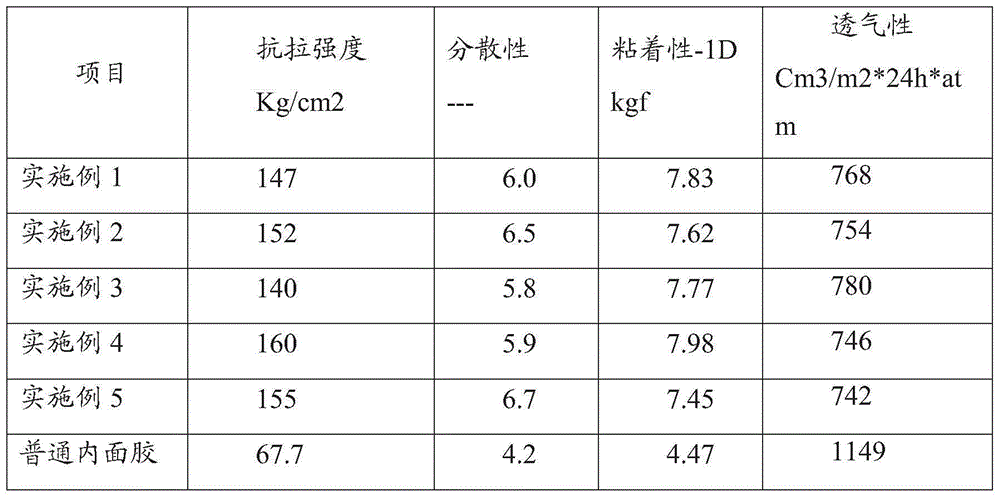

Examples

Embodiment 1

[0035] Raw material components: 28 parts of natural rubber, 37 parts of emulsion polystyrene butadiene rubber, 35 parts of chlorinated butyl rubber, 20 parts of high wear-resistant carbon black, 25 parts of general-purpose furnace black, 35 parts of flaky nano-kaolin, 1.5 parts of anti-aging agent BLE-W, 4 parts of active agent ZnO, 4 parts of active agent stearic acid, 4 parts of tackifying resin RT-1102, 3 parts of vulcanizing agent S-325, 1 part of accelerator alkylphenol disulfide TB710, 2 parts of accelerator agent TBBS, 1 part accelerator TMTD and 12 parts operating oil TDAE-22.

[0036] Preparation process: (this process is carried out in a 270L internal mixer)

[0037] 1): Mix natural rubber, flaky nano-kaolin, polystyrene-butadiene rubber, chlorinated butyl rubber, active agent, tackifier, and anti-aging agent for at least 40 seconds.

[0038] 2): Put in carbon black, general purpose furnace black and 1 / 2 operating oil and mix for at least 30 seconds,

[0039] 3): P...

Embodiment 2

[0046] Raw material components: 32 parts of natural rubber, 52 parts of emulsion polystyrene butadiene rubber, 52 parts of chlorinated butyl rubber, 25 parts of high wear-resistant carbon black, 30 parts of general furnace black, 52 parts of flaky nano kaolin, 2 parts of old anti-corrosion Agent BLE-W, 5 parts of active agent ZnO, 3 parts of active agent stearic acid, 5 parts of tackifying resin RT-1102, 5 parts of vulcanizing agent S-325, 1.5 parts of alkylphenol disulfide TB710, 3 parts of accelerator TBBS, 1.5 parts accelerator TMTD and 15 parts process oil TDAE-22.

[0047] The preparation process is the same as in Example 1.

Embodiment 3

[0049] Raw material components: 30 parts of natural rubber, 40 parts of emulsion polystyrene butadiene rubber, 38 parts of chlorinated butyl rubber, 20 parts of high wear-resistant carbon black, 28 parts of general furnace black, 40 parts of flaky nano kaolin, 2 parts of old anti-corrosion Agent BLE-W, 4 parts of active agent ZnO, 2.5 parts of stearic acid, 5 parts of tackifier RT-1102, 4 parts of vulcanizing agent S-325, 3 parts of alkylphenol disulfide TB710, 3 parts of accelerator TBBS, 1.0 parts accelerator TMTD and 10 parts process oil TDAE-22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com